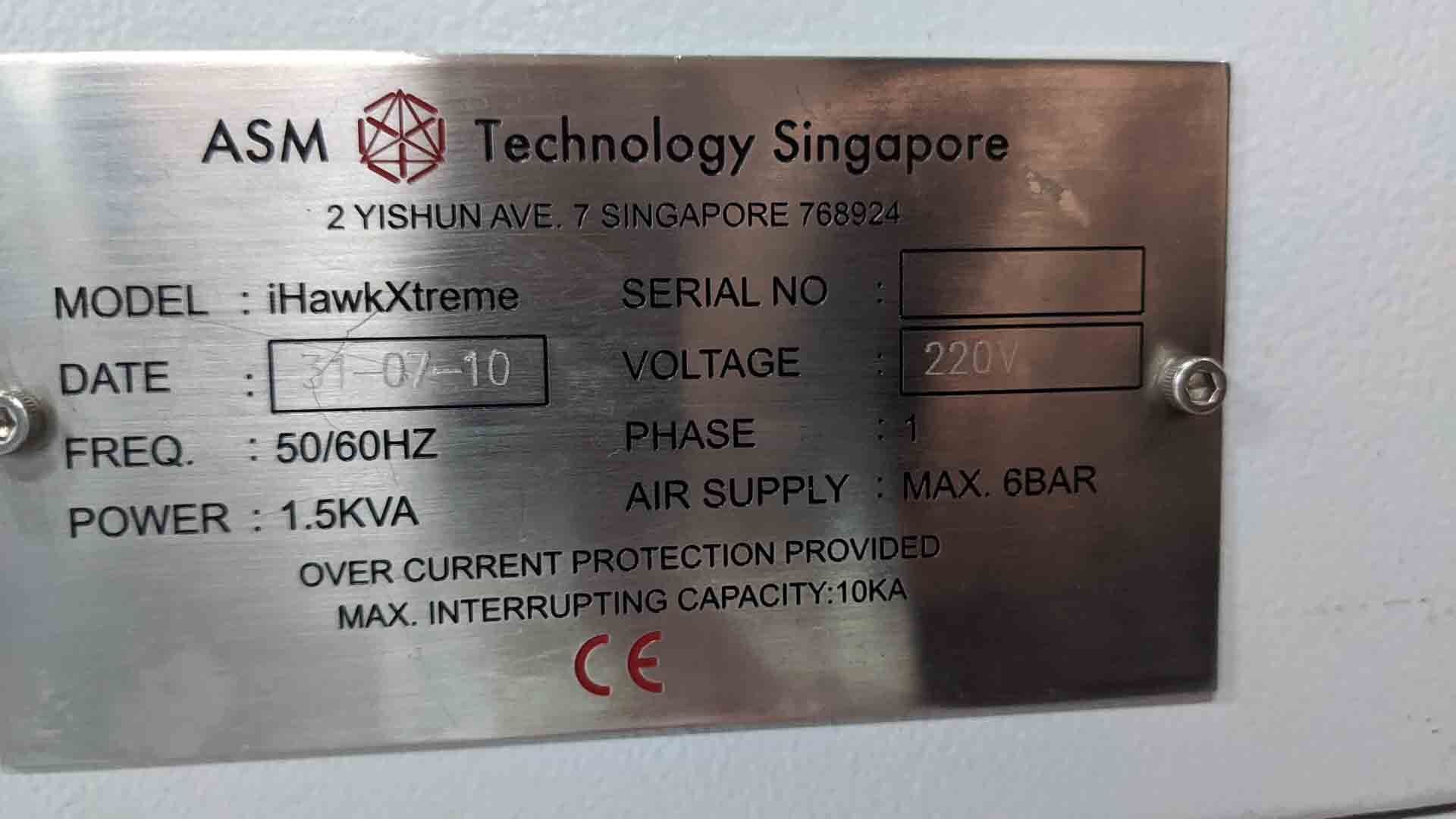

Used ASM iHawk Xtreme #293600181 for sale

URL successfully copied!

Tap to zoom

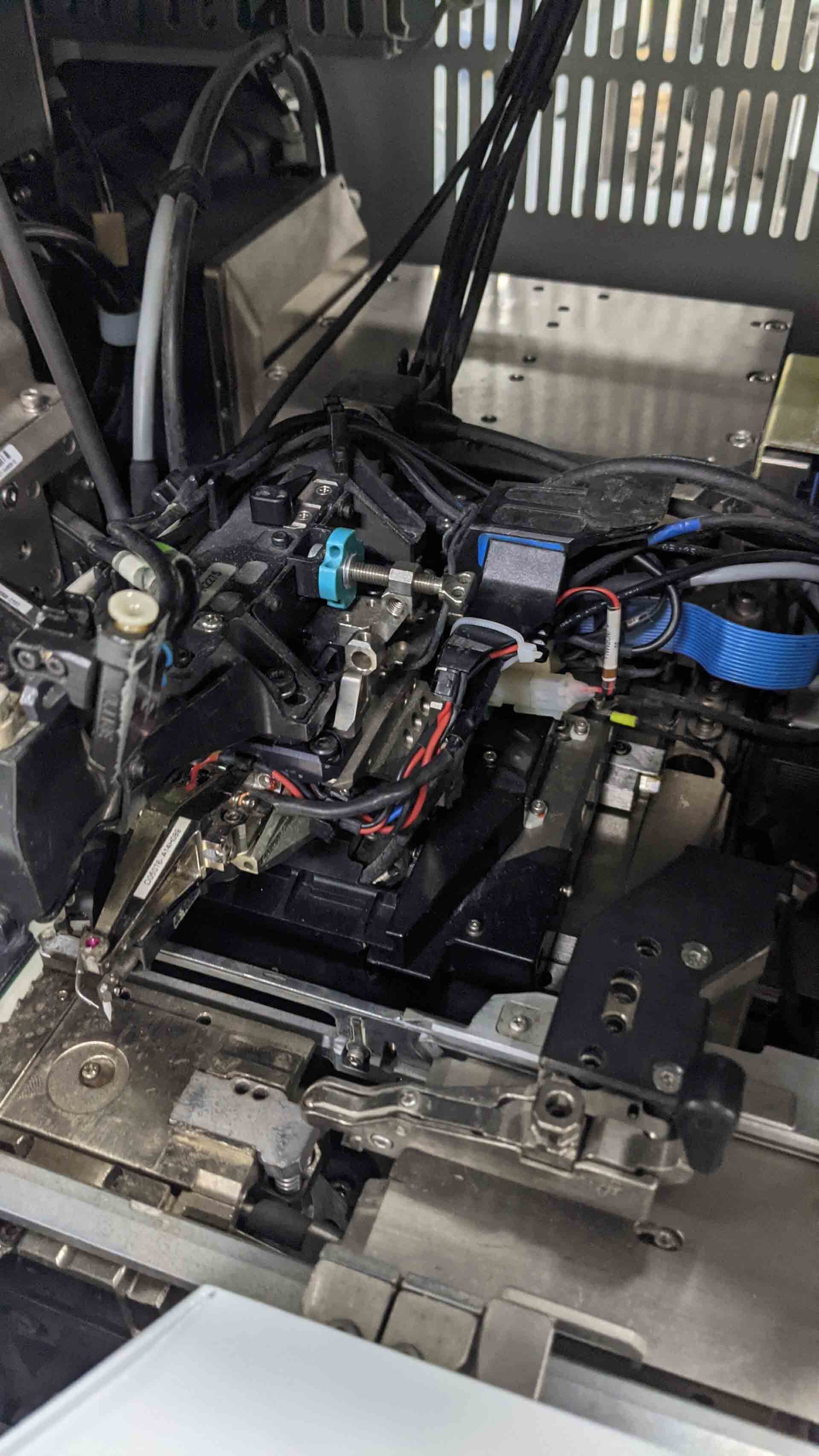

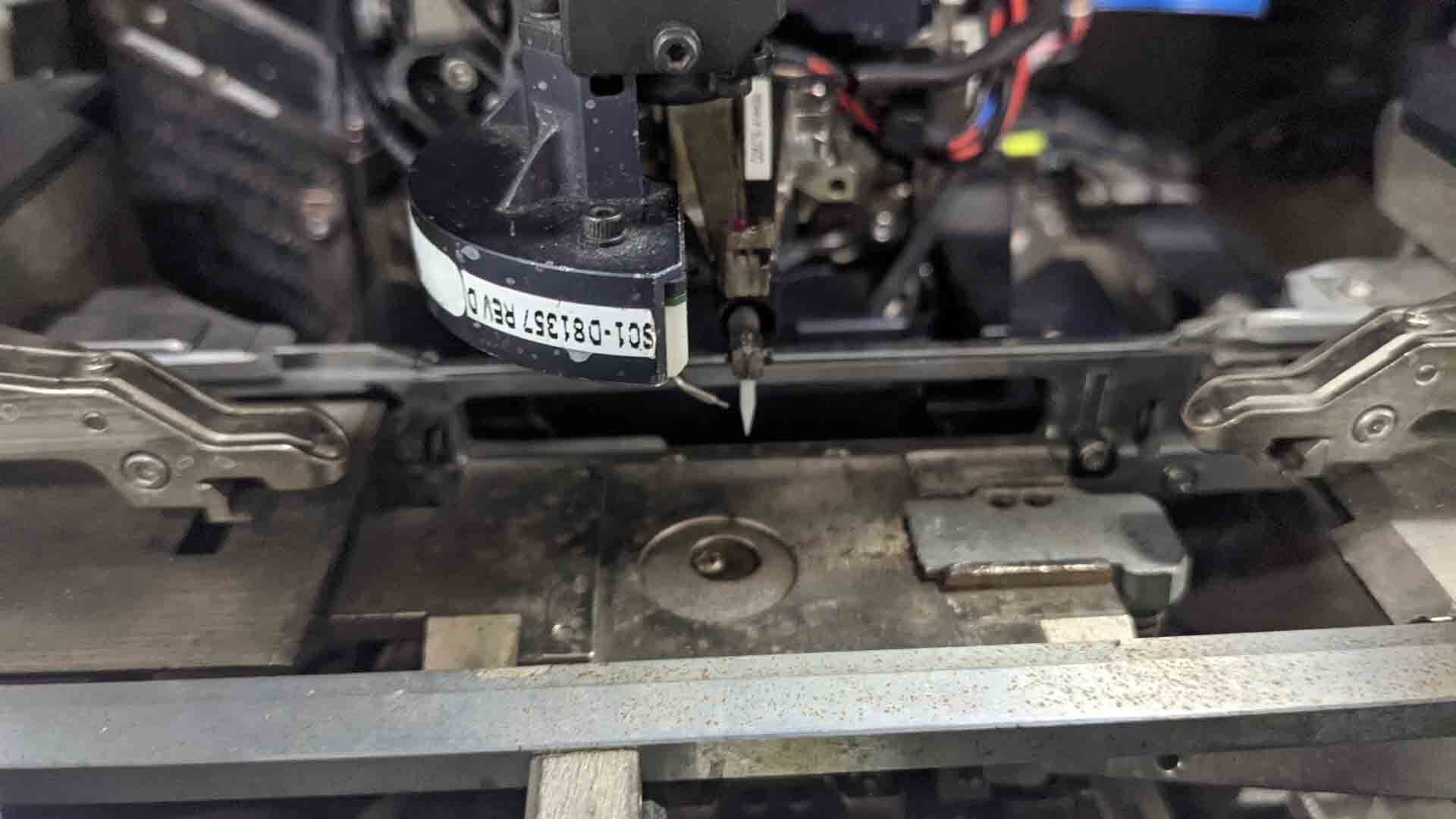

ASM iHawk Xtreme is an innovative ultrasonic bonder designed for quickly and accurately bonding a wide range of substrates. It is an all-in-one equipment that blends advanced ultrasonic bonding and sophisticated process control with an operator-friendly interface. The system utilizes a style of high frequency welding that is ideally suited for small medical device assembly and the production of precision micro-bonded components. Its high degree of accuracy and intuitive ease of use makes ASM IHAWK-XTREME bonder an indispensable tool for manufacturers of high-precision components, medical products, and components used in the aerospace and automotive industries. I HAWK XTREME bonder features a powerful and reliable VX90 ultrasonic transducer, designed to operate efficiently up to 25 kHz and deliver uniform, controlled welds. The sophisticated control package enables the unit to reach different levels of power, dependent on the application requirements. The machine is designed to minimize setup time and material consumption, thanks to its intuitive selection menus and graphical user interface. The intelligent process controls, meanwhile, enable precise material characterization to ensure consistent weld results. IHAWK-XTREME bonder also offers a wide range of optional features to accommodate unique production requirements. These include a range of accessories, such as specialized tooling and weldable materials as well as a scan and verification tool that reinforces precision and accuracy in production. The asset is also compatible with a number of automation and supply chain solutions, enabling manufacturers to develop production systems and optimized production lines. In addition to its reliable, accurate performance and operator-friendly interface, iHawk Xtreme bonder also delivers excellent safety features. Its lightweight and compact form factor minimizes operator fatigue, while the integrated safety model helps to eliminate unnecessary risks. The high-quality, durable design offers reliable performance and increased service life, while the integrated maintenance equipment helps to reduce downtime. The entire system is designed to offer simple, stress-free operation, making it an essential tool for any advanced production facility.

There are no reviews yet