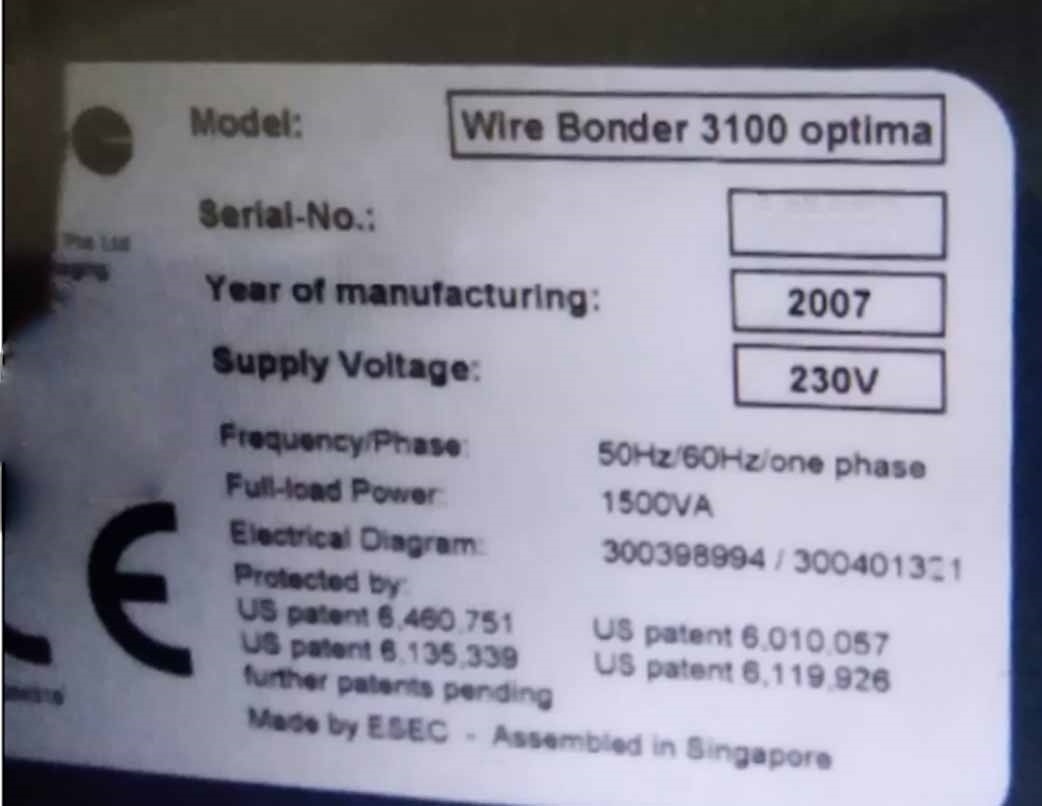

Used ESEC 3100 Optima #9220330 for sale

URL successfully copied!

Tap to zoom

ESEC 3100 Optima is an automated bonding equipment that is designed to address a variety of applications. With the ability to bond components into complete assemblies, its versatile design enables operators to bond all types of projects, including SMT and through-hole areas on the same board. 3100 Optima is the perfect choice for applications such as handheld electronics, computers, telecommunications and consumer electronics. ESEC 3100 Optima is equipped with a patented CCD optical measurement system which monitors the entire production process. The unit can detect component position, component size and component center at speeds of up to 480 components/minute. This makes the Optima suitable for a large range of products and improves efficiency. An ergonomic LED-touch panel makes operator navigation and oversight easy and simple. The panel features a wide range of parameters that can be adjusted to accommodate changing production conditions. 3100 Optima is designed for total integration into the production line with its ability to load and unload boards simultaneously at both ends of the machine. The tool has a standard board width of 433mm with an optional board width of 610mm; it also has a variable front stop, range of accessories and conveyor options available. ESEC 3100 Optima operation is monitored and controlled by a dedicated embedded controller that can be easily integrated into the inter-process communication structure within the production line. 3100 Optima utilizes lead-free compatible solder fluxes for optimal performance. The asset offers an advanced process design with its unique jetting head. This decrease maintains process consistency and improves on throughput, precision and accuracy. The solder jetting feature also allows operators to reduce their operating costs by using smaller quantities of flux by 40-60%. The model also includes advanced diagnostics for production monitoring. Built-in tooling and integrated process feedback allow operators to track flux performance and consistency, monitor temperature and detect any anomalies that could cause defects. ESEC 3100 Optima is an innovative equipment designed to provide reliable, accurate and efficient throughput. Its built with advanced technology that helps operators reduce production costs and increase the quality of their final product. With the Optima, customers can expect improved throughput, precision and accuracy in their production processes.

There are no reviews yet