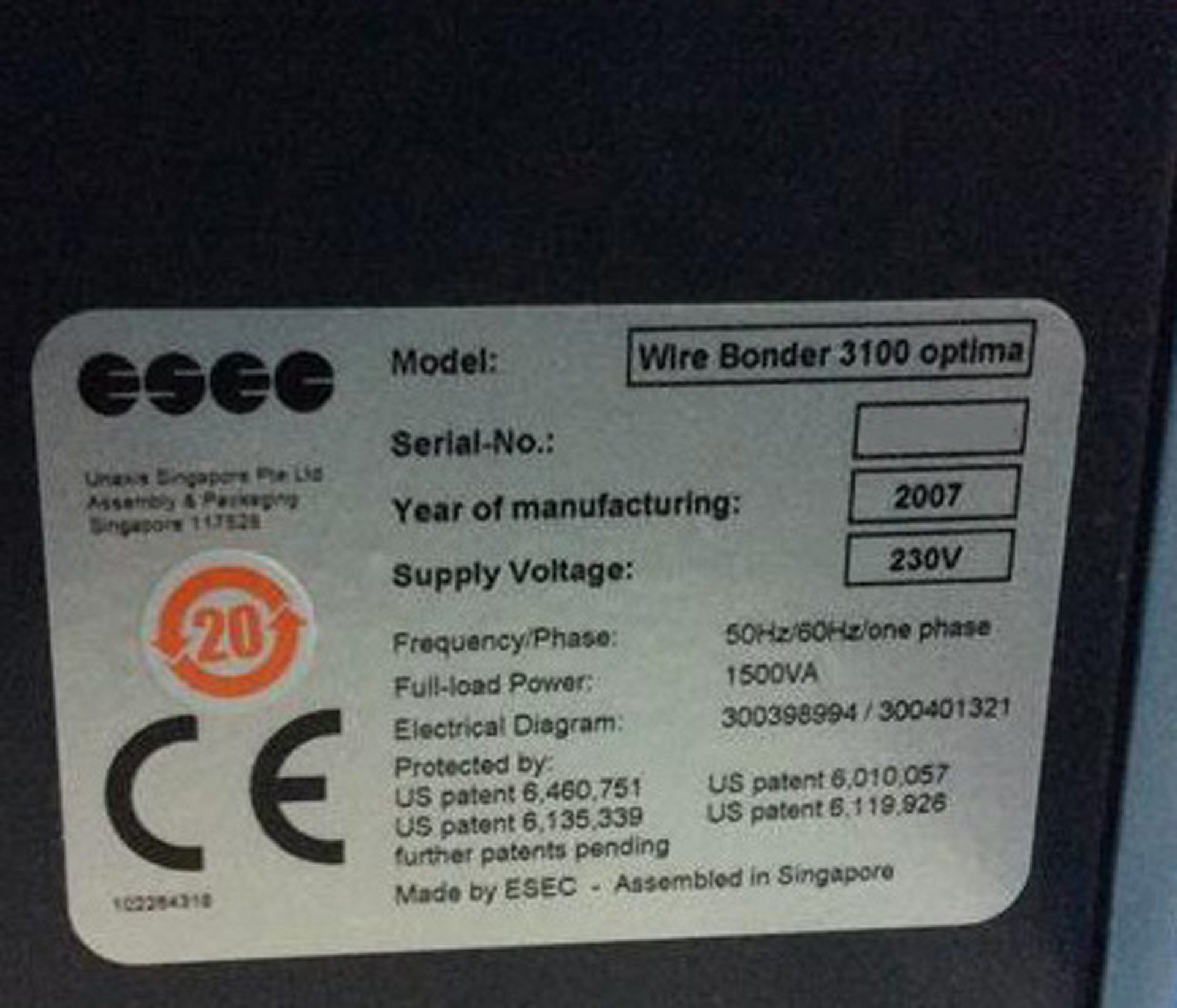

Used ESEC 3100 Optima #9373285 for sale

URL successfully copied!

Tap to zoom

ID: 9373285

Wire bonders

Auto focus capability

Cognex base

(4) Magazines for QFP84 L/F

Loader and unloader platform

Vacuum tank: 1.5 L

Noise level: < 75dB

Bond head:

Bond placement accuracy: ± 2.5 µ (3 Sigma)

Wire cycle time: 56 minutes per second (Standard loop)

Fine pitch: 35 µm in line at 3 Sigma

Maximum bonding area: 52 x 70 mm / 2 x 2.75"

Looping:

Maximum loop height: 50-70 µm

Maximum wire length: 9 mm per 360 mils

Wire sway:

Wire length: <2.54mm (0.100"), ± 2.5 µm at 3 Sigma

Wire length: >2.54mm (0.100"), ± 1% wire length at 3 Sigma

Magazine handler:

Gripper with self adjusting clamps

Tunnel buffer system

Materials:

Wire:

Gold wire

Diameter: 15-75 µm per 0.6-3.0 mils

Capillary:

Length: 11.1mm per 0.437"

Diameter: 1.58mm per 1/16"

Lead frame:

Length: 100-270 mm / 4.0 to 10.63"

Width: 15-84 mm / 0.6 to 3.3"

Thickness: 0.1-0.8 mm / 4 to 32 mils standard

Pad downset: 0-2.3 mm / 0 to 90 mils

Maximum pitch: 90 mm / 3.5"

Magazines:

Length: 125-275 mm / 4.92 to 10.82"

Width: 20-120 mm / 0.78 to 4.7"

Magazine type: Open on both sides

Air consumption:

Normal:

Maximum: 65 nl per minute (At P: 5 Bar)

Venturi:

Maximum: 230 nl per minute

Air quality:

Maximum: 1.4 g/m³ (SPT) Water contamination

Maximum: 0.1 mg/m³ (SPT) Oil contamination

Maximum: 5 mg/m³ (SPT) particles

Maximum particle size: 5 µm

Vacuum:

Type: 15 nl per minute

Minimum: -0.8 ± 0.05 Bar / -24" Hg ± 1.5" Hg

Maximum: -0.9 Bar / -27" Hg

Temperature range:

Maximum drift: ± 2.5°C

Maximum: ± 30°C

Minimum: ± 15°C

Compressed air: 5-8 Bar / 73-116 psi

Power supply:

204-230 V, 50/60 Hz, 2900 W

100-120 V, 50/60 Hz, 1200 W

DVD Drive

CE Marked

2006-2007 vintage.

ESEC 3100 Optima is an automated wire bonder developed by ESEC Corporation. 3100 Optima is a professional automated wire bonder designed to provide accurate and repeatable wire bonding for a variety of circuit board applications. The wirebonder offers a range of features such as high accuracy and repeatability due to its superior motion systems; advanced process monitoring capabilities for better control over wire bond parameters and process conditions; and a robust construction that is suitable for volume production of wire bond products. ESEC 3100 Optima is constructed from a heavy-duty aluminum alloy frame with a durable powder coated finish that ensures the highest quality and reliable operation of the wire bonder. The robust construction also guarantees a long service life for the bonder as it is designed to withstand the rigors of production environments. The device comes with an intuitive user-friendly interface that allows for quick and easy configuration and operation via a series of buttons and menus. 3100 Optima utilizes a lead-free bonder head adapter and a variety of tooling to accommodate a wide range of different copper wire sizes and shapes. The standard work envelope for ESEC 3100 Optima is 12.7" x 9.5" x 13.78". The machine's two-axis, four-axis motion system ensures accurate and repeatable wire bonding as it ensures that the bonder head accurately follows the pattern as specified via the user interface. The machine's high accuracy and repeatability is further enhanced with the use of its advanced process monitoring capabilities that allow for better control over wire bond parameters and conditions via real-time feedback from sensors. 3100 Optima wire bonder comes equipped with several safety features to ensure a safe and reliable wire bonding process. These include perimeter guarding barriers that securely encase the entire wire bonder head to prevent any unauthorized access into the area, and a switch that allows operators to manually control the movement of the bonder head. The perimeter guards also contain anti-fatigue mats that prevent any accidental damage to the wire bonders head. Furthermore, the wirebonder also comes with a wide range of accessories such as, a spool holder, a wire puller, and a variety of other consumables and tooling. Overall, ESEC 3100 Optima wire bonder offers high accuracy, repeatability, and safety for a professional and reliable automated wire bonding process. Its robust construction and intuitive user-friendly interface makes it suitable for volume production of bond products. 3100 Optima also provides advanced process monitoring capabilities that allow for greater control over wire bond parameters and conditions. The wire bonder is suitable for a wide range of different copper wire sizes and shapes, and also provides several safety features to ensure safety and reliability of the system.

There are no reviews yet