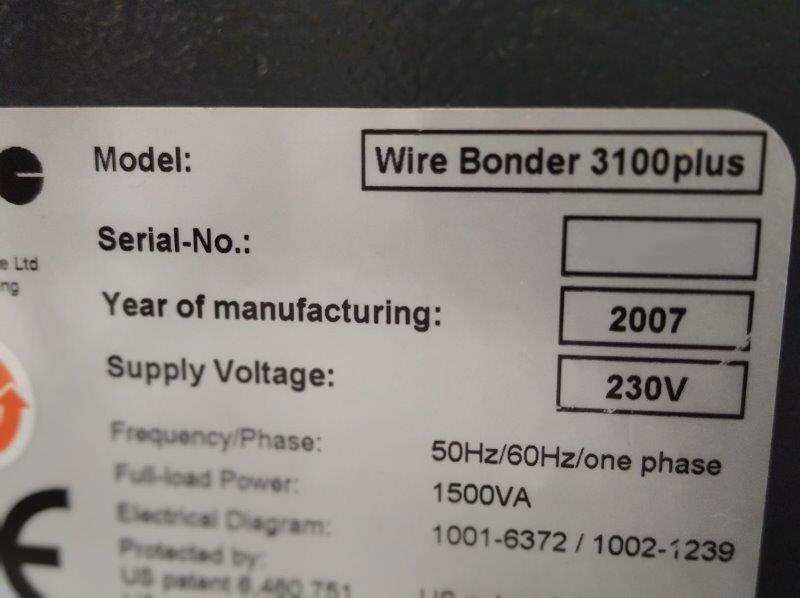

Used ESEC TSUNAMI W3100 Plus #9360822 for sale

URL successfully copied!

Tap to zoom

ESEC TSUNAMI W3100 Plus is a high-performance, automated wedge bonder for interconnecting components in semiconductor devices. The equipment is designed to meet increasing demands for higher throughput speeds, improved accuracy, and greater flexibility in bond applications. W3100 Plus offers unparalleled control over the entire bonding process, from component placement to the final wire bond. ESEC TSUNAMI W3100 Plus operates at speeds of up to 12,000 wires per hour with unparalleled accuracy and repeatability. It can handle a wide range of wire sizes, from 0.015" to 0.250". The system can handle a variety of wire materials, including copper alloys, gold, silver, and aluminum. The bonder utilizes a closed-loop control unit that allows for continuous monitoring and adjustment of the bond process based on input parameters. This ensures consistent, high-quality bonds with each cycle. The machine is equipped with precision fine-pitch wire pitching and placement components, including a highly accurate six-axis robot and dual-axis camera. The robot is capable of self-centering and positional fine-tuning of components for precise placement. It can accurately place, cut, and bond multiple wires in a single cycle, allowing for greater flexibility in the design and fabrication of products. The tool also includes a vision asset and an intelligent package recognition model. The vision equipment continuously monitors each bond location and records images taken before and after each bond to ensure a precise process. The intelligent package recognition system allows the bonder to identify the and size of the die and substrate, as well as their position in the package, to ensure precise placement during the bonding process. W3100 Plus is also equipped with multiple bank storage and transport systems, allowing for the efficient management of components as they enter and exit the unit. This feature helps to minimize the risk of misplacement or damage to components in the machine, and ensures that the most efficient bonding solutions can be achieved. The tool has a user-friendly, intuitive graphical interface that allows for easy control of all parameters during the bonding process. It also includes real-time data monitoring that allows for easy monitoring of asset performance and troubleshooting. The user interface is user friendly and includes an intuitive on-screen display that clearly displays all relevant data. The TSUNAMI ESEC TSUNAMI W3100 Plus bonder provides a powerful and highly reliable solution for integrated circuit and semiconductor device production. This model offers precision, repeatability, and a spacious work area for faster and more efficient processing of parts. This equipment offers excellent throughput and accuracy and is suitable for a variety of wire-bonding solutions.

There are no reviews yet