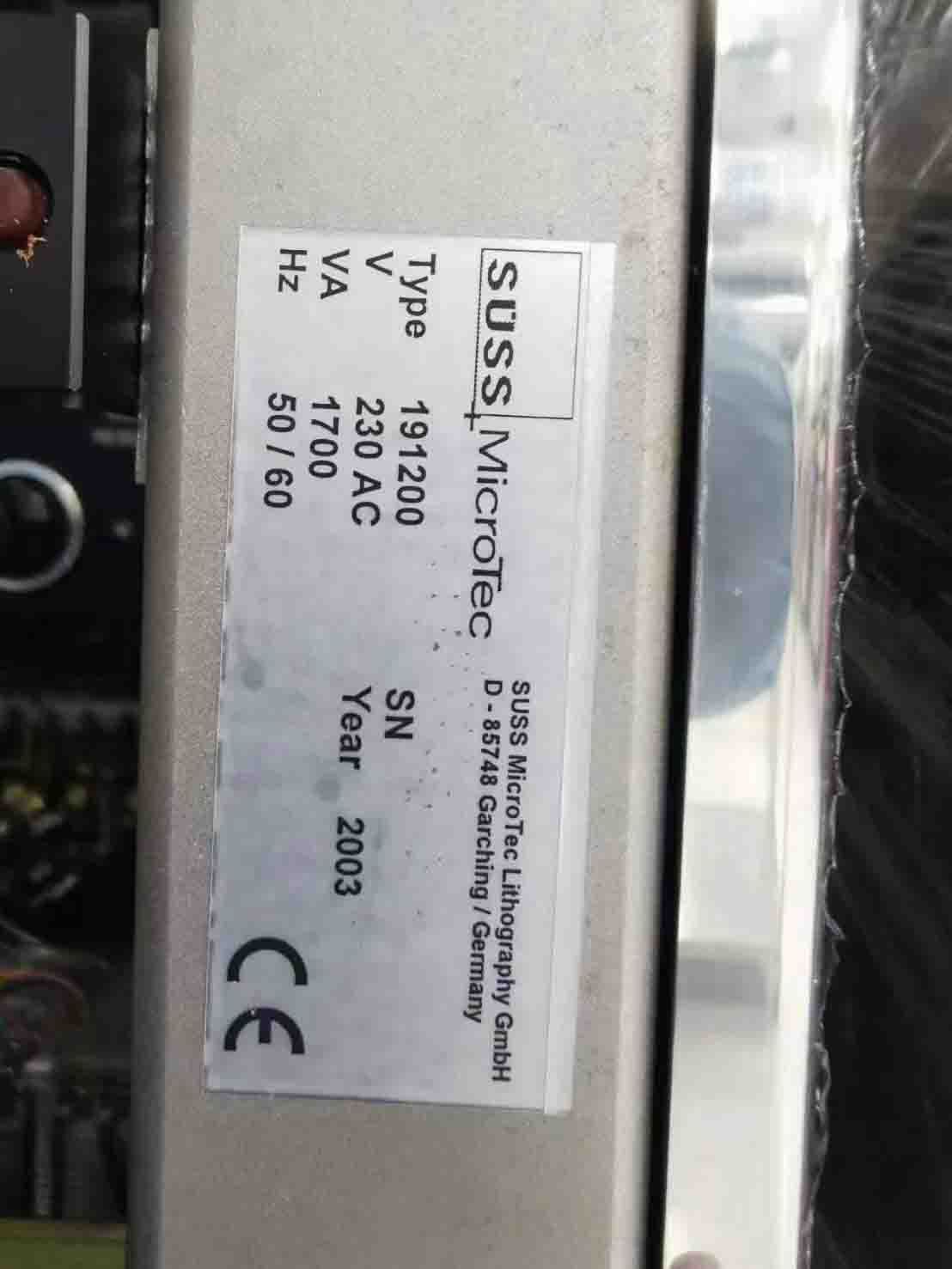

Used KARL SUSS / MICROTEC ABC 200 #293639489 for sale

URL successfully copied!

Tap to zoom

KARL SUSS / MICROTEC ABC 200 is an advanced bonder equipment, allowing fine wire and flip chip bonds to be completed with a high level of precision. It is designed for applications needing precise bonding and gripper processes, and is ideal for a wide range of diverse product manufacturers. The system utilizes a comprehensive infrastructure for precise processing that is equipped with a vacuum powered application head, and precise real-time software control. This is supplemented by adjustable front and rear entry doors, together with the reduced volume of the working area, adding to the unit's accuracy. With the built-in locator and orientation machine, MICROTEC ABC200 is able to precisely place the components, making it ideal for high production settings. The integrated robotics also allow for simple and quick setup as well as easy handling, loading, and unloading of parts. Thanks to the robust design, with its precise and protective integration of grips, the tool can handle high workloads without compromising quality. Programming the entire process is effortless, with a user-friendly GUI that allows total control and flexibility. KARL SUSS ABC-200 features high-performance motion controllers that offer fast speed control. The mechanics are optimized with linear X-Y axes, providing a boost in the speed of the wire bonding process. Additionally, the flexible controls for the bonder heads ensure that your bonds are always accurate. The asset allows for quick integration and thermal optimization within the process, with the ability to configure up to ten heat sizes from the default settings. Furthermore, if higher resolution is required, then the dynamic heat can be used to maximize flexibility. In conclusion, KARL SUSS ABC 200 is a suitable choice for a wide array of different manufacturers looking for a precise bonder model for their needs. Its adjustable entry doors and precise software control make it the perfect tool for creating high-quality products. The motion controllers and robotic components also help improve the speed and quality of the assembly process, while making it easier to optimize the entire process with thermal controls.

There are no reviews yet