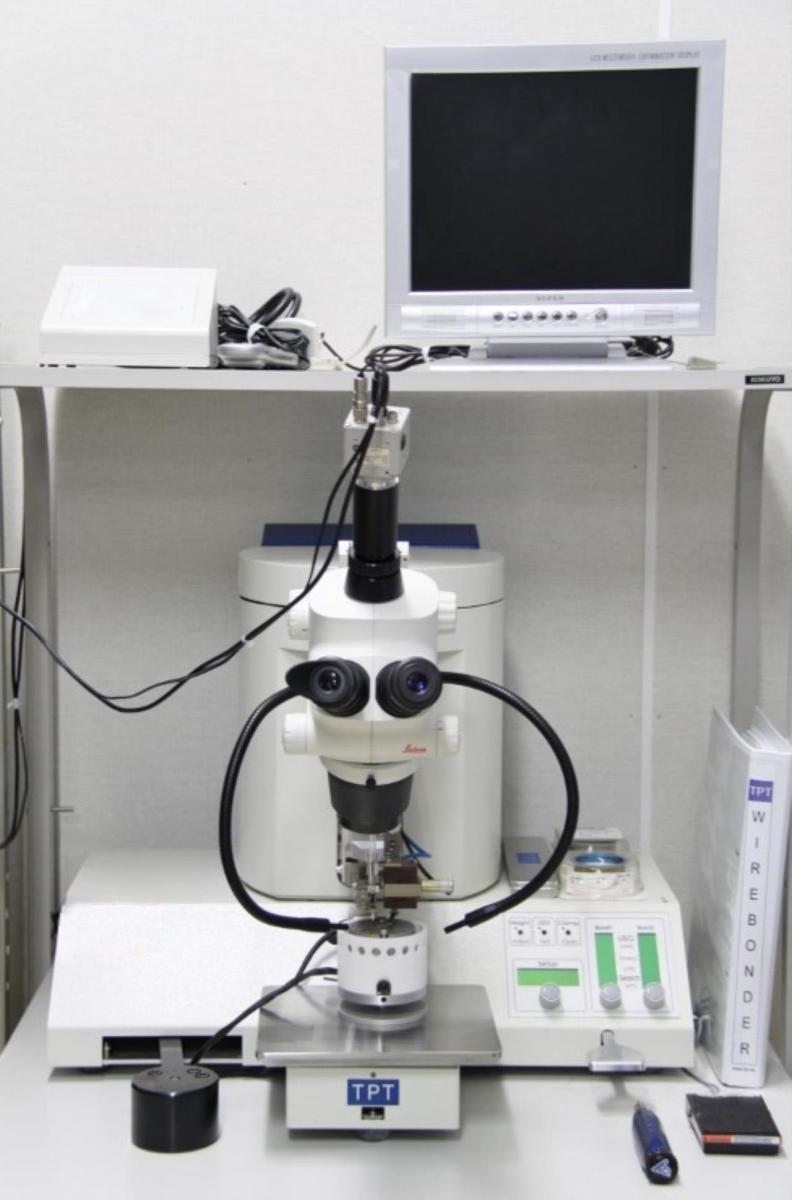

Used TPT HICKMANN HB 10 #9171934 for sale

URL successfully copied!

Tap to zoom

ID: 9171934

Vintage: 2007

Wire bonder

Bonding methods:

Wedge-wedge

Ball-wedge

Ribbon bonding

Bumb-bonding

Gold wire diameter: 17-75 µ (0.7 - 3 mil)

Aluminium wire diameter: 17-75 µ (0.7 - 3 mil)

Ribbon size: Maximum 25 x 250µ (1x8 mil)

Ultrasonic system: 63.3 kHz Transducer PLL control

Ultrasonic power: 0-10 Watt output

Bond time: 0 -10 sec

Bond force: 5 - 150 cNm (350cNm Option)

Bonding tool: 1.58 φ 19 mm length (0.0624" x 0.750")

Motorized wire spool: 50.8 mm (2")

Wire termination: Bond head tear / Clamp tear

Wire feed angle: 90°

Clamp movement: Motorized, up / Down

Ball size control: Electronic

Motorized Z travel: 17 mm (0.67")

Throat depth: 165 mm (6.7")

Fine table motion: 10 mm (0.4")

Mouse ratio: 6:1

Temperature controller: Up to 250°C +/- 1°C

Electrical requirements: 100 - 240V +/-10%, 50/60 Hz, 10A maximum

Physical dimensions: 680 mm (27") x 640 mm (25") x 490 mm (19")

Accessories:

Heater stage: 100 x 100mm

Bondstart kit

Manual Z

Pick & place

Pick and place heater stage

Pull tester

Spotlight targeting system

CE Marked

2007 vintage.

TPT HICKMANN HB 10 is an automatic lower section bonder designed for efficiently welding and joining different kinds of materials, such as rubber and metal. This bonder has 10 individual welding ovens which allow for greater precision in the welding process. It also has a wide range of options for controlling the temperature and pressure of each oven. TPT HICKMANN HB10 also features a large, easy to use LCD display that provides operators with a wealth of information and control options. The display provides real-time readings of the process details and reports any malfunctions or problems that may occur during operation. HB 10 also has a load and unload system that allows for materials to be moved from one station to the other quickly and precisely. This system also allows the operator to adjust cooling times and other parameters depending on the material being welded. It has a durable construction with stainless-steel surfaces and rust-resistant materials, ensuring good stability and longevity. Additionally, HB10 comes equipped with a range of safety features. This includes a sensor system which can detect potential hazards and alert the operator, as well as a variety of emergency shutoff mechanisms that will ensure the bonder's safety in case of an emergency. Overall, TPT HICKMANN HB 10 provides an efficient and reliable solution for welding and joining of materials such as rubber and metal. Its user-friendly LCD display allows for easy operation, while its durable construction and range of safety features make it a safe and reliable machine. With its wide range of options and advanced features, this bonder is ideal for a variety of welding and joining applications.

There are no reviews yet