Used TPT HICKMANN HB16 #9137362 for sale

URL successfully copied!

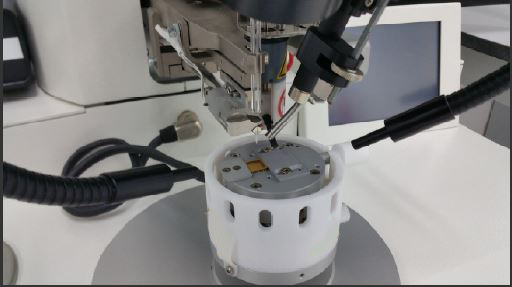

Tap to zoom

ID: 9137362

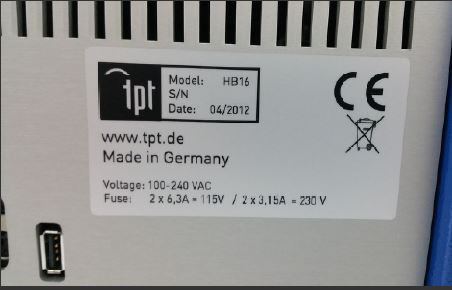

Vintage: 2012

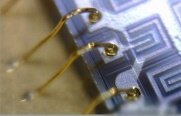

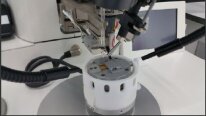

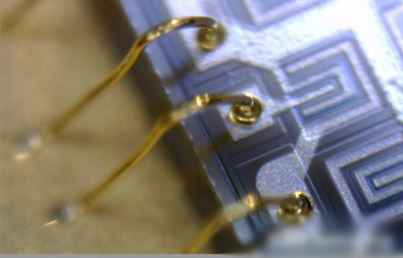

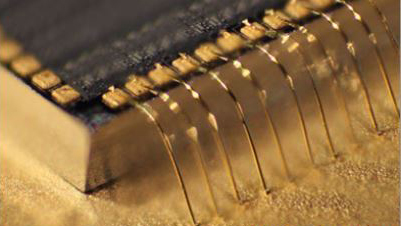

Semi-automatic thermosonic ball / Wedge bonder

Bump and ribbon bonding

17~ to 75~ Wire and 25~ x 250~ ribbon

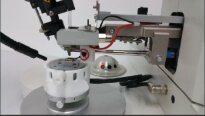

6,5" TFT Touch screen

Deep-access bond head: 16mm

Bond arm length: 165mm

100 Program storage capacities

Motorized Z- & Y-axis

Programmable loop profile

USB Backup

Electronic ball size control

Specifications:

Bonding Method: Wedge-wedge, ball-wedge, ribbon & bump-bonding

Gold wire diameter: 17-75µ (0,7-3 mil)

Aluminium wire diameter: 17-75µ (0,7-3 mil)

Ribbon size: Max. 25 x 250MI (1x8 mil)

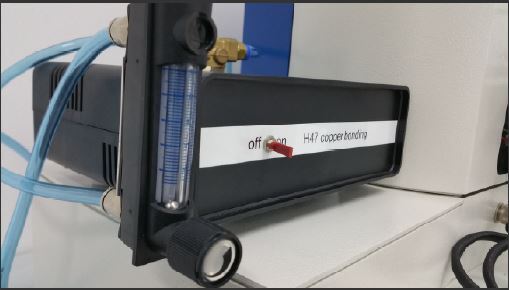

Ultrasonic system: 63,3 kHz Transducer PLL Control

Ultrasonic power: 0-10 Watt output

Bond time: 0-10 sec

Bond force: 5 - 150 cNm (350cNm option)

Bonding tool: 1,58 x 0.19 mm length (0,0624" x 0,750")

Motorized wire spool: 50,8 mm ( 2")

Wire termination: Bond head tear / Clamp tear

Wire feed angle: 90°

Clamp movement: Motorized, Up / Down

Ball size control: Electronic

Motorized Z travel: 17 mm (0,67")

Motorized Y travel: 10 mm (0,27")

Throat depth: 165 mm (6,7")

Fine Table motion: 10 mm (0,4")

Mouse ratio: 6:1

Temperature controller: Up to 250°C +/- 1°C

Electrical requirements: 100 - 240V +/-10% 50/60 Hz 10A max

CE Marked

2012 vintage.

TPT HICKMANN HB16 is a special high speed precision bonder designed with automated and high precision processes for laser welding, wire bonding, and other types of assembly. This type of bonder is suitable for high volume and precision applications where fast speeds and excellent results are desired. TPT HICKMANN HB 16 bonder comes with a wide range of work envelope designs. Its features include a large 19.7" x 15.75" table with X, Y and Z axial motion. It utilizes a precision-controlled twin air bearing system to ensure smooth and precise operation during installation and assembly. Its rear modules can be equipped with a range of laser sources, including fiber, diode, and YAG varieties for laser welding. The front module is divided into multiple sections, each of which can be outfitted with standards tools like twistband, coding, pin insertion, blade crimping, soldering iron heads and other types of assembly tools. It also features special ultrasonic and wire-bonding heads. These heads can handle ultrafine wires up to 25 μm in diameter. Every section has its own T-slot module which allows the operator to install and customize the tools that best suit each application. HB16 is designed to make the assembly processes more efficient and productive. It has been designed to minimize the time and effort required for reliable interconnections using high precision technologies. The bonder has a user-friendly 5.7" touchscreen, which allows the operator to adjust parameters, create new settings, and monitor the status of the bonder. In order to increase lifetime reliability and performance, TPT HICKMANN HB16 has a range of sophisticated safety mechanisms installed. Its integral safety systems include E-stop, light curtains and aluminium doors that are automatically triggered during working operations. These safety systems ensure that the machines are only operated by qualified and trained personnel. Overall, HB16 bonder is an innovative machine that will help streamline and improve the impactful process of assembly. With its advanced features, high performance, and user-friendly software, this bonder is an ideal choice for high volume applications that require precision results.

There are no reviews yet