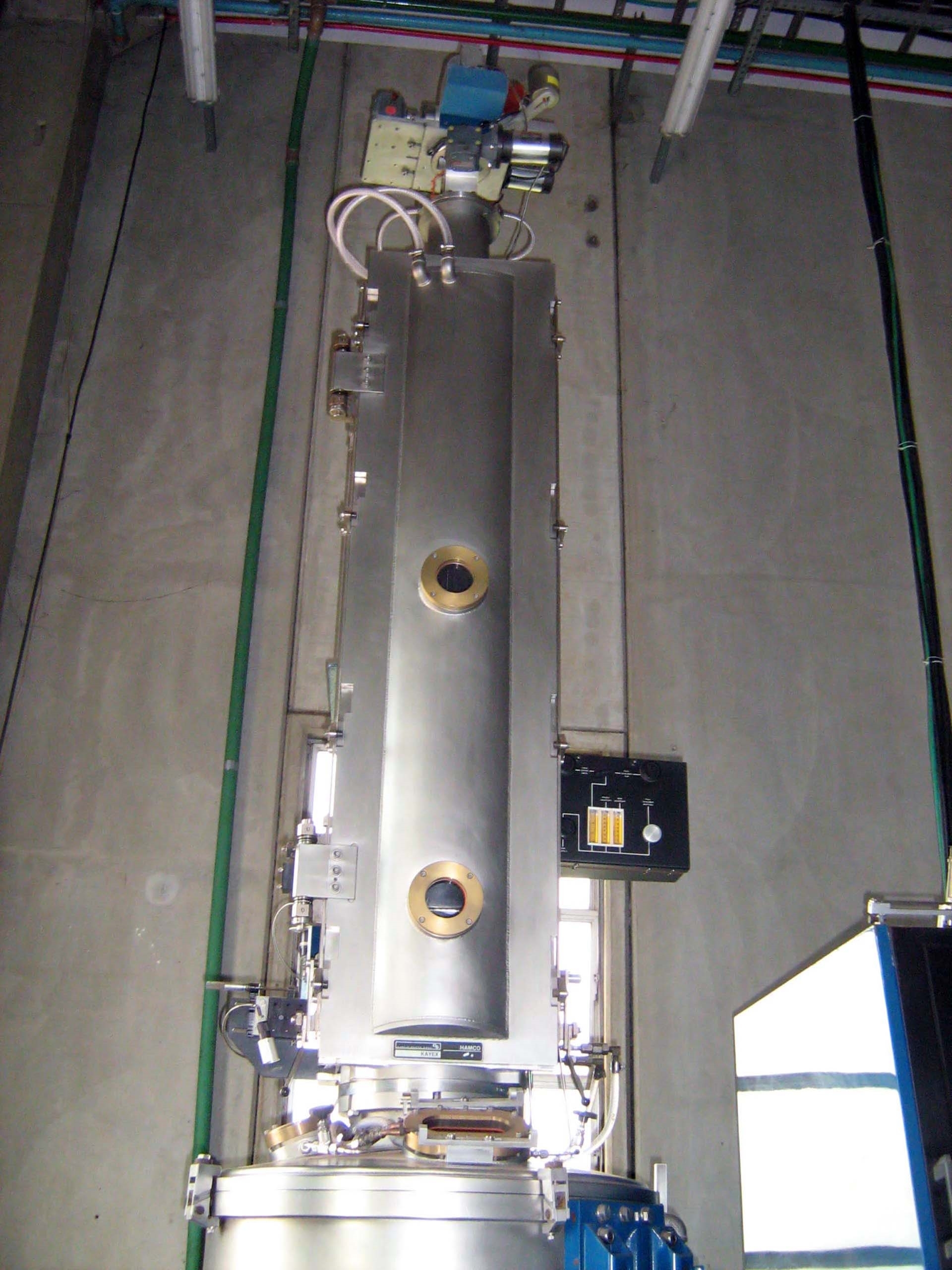

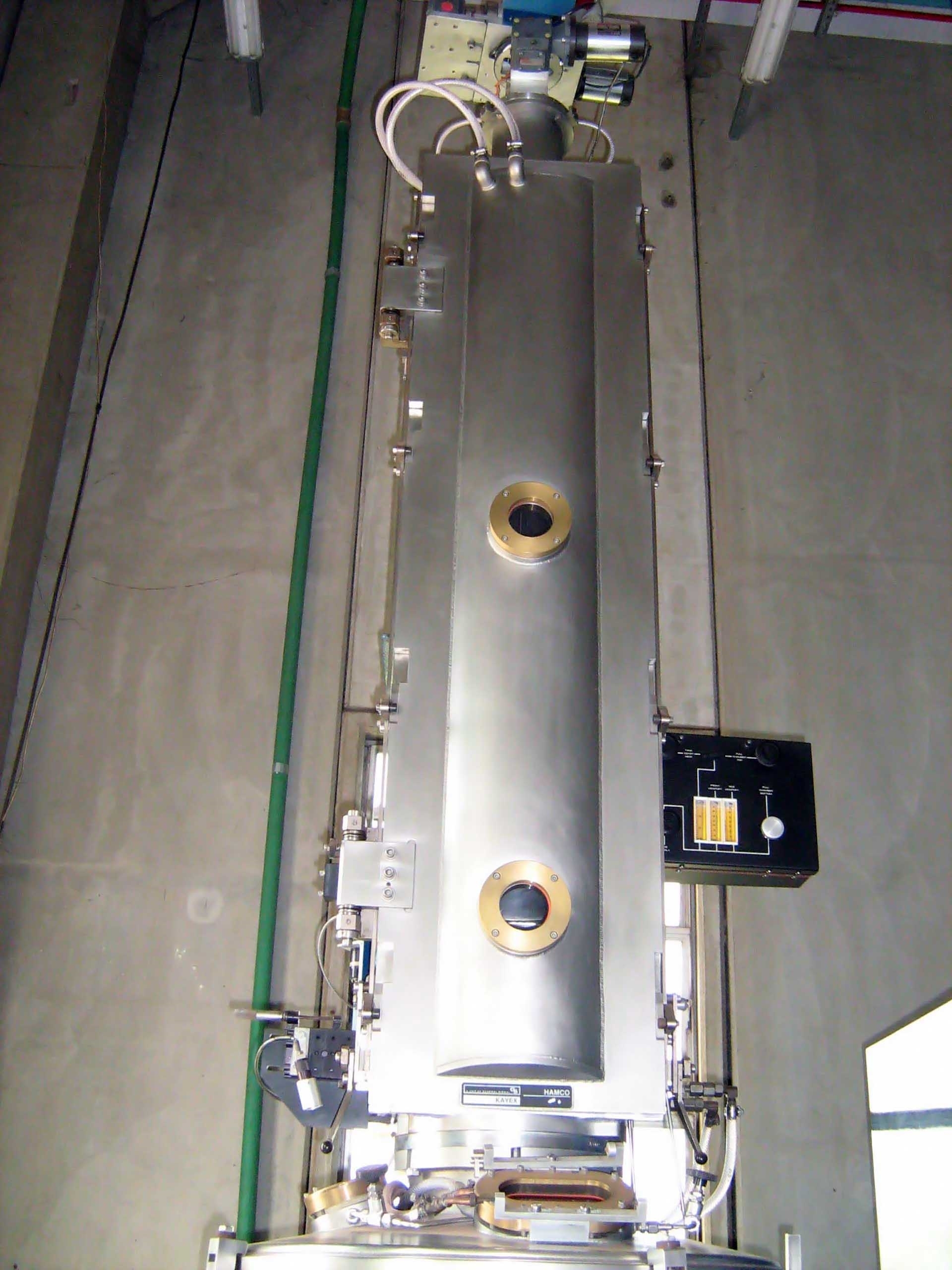

Used KAYEX / HAMCO CG 6000 #9229973 for sale

URL successfully copied!

Tap to zoom

ID: 9229973

Oven

For silicon casting and mono crystalline growth

With control panel

Transformer

Vacuum pump (Turbo)

Manual data

Vacuum pump: OMEL SA

BLN 250 / 240

With WEG motor

25 CV / 460 V / 33.0 A / 1170 RPM

Auxiliary vacuum pump:

With motor: 0.75 CV / 460 V / 2.25A / 1750 RPM

Hydraulic pump:

Motor: 0.5 CV / 460 V / 1,05A / 1725 RPM

Power requirements: 460 V / 300 A, 400 V / 350 A.

KAYEX / HAMCO CG 6000 crystal growing, sawing and slicing equipment is a versatile system designed for use in multiple facets of the crystal growth, slicing and sawing process. This unit rapidly and accurately grows, saws and slices single crystals, wafers, and multi-level crystals to cater to a range of scientific and industrial applications. KAYEX CG 6000 machine features a direct drive stepper motor controlled by a CNC axis control tool, and is comprised of three major components: crystal growth, sawing and slicing. HAMCO CG 6000's crystal growth component utilizes a two-stage process with a primary stage for crystal nucleation and a secondary stage for crystal growth. The crystal growth process is integrated with a dedicated controller, enabling users to precisely control the gas concentration and temperature necessary for crystal growth. CG 6000's sawing component utilizes diamond-impregnated carbide blades for precise sawing of various crystalline materials. By using a closed loop asset, KAYEX / HAMCO CG 6000 precisely controls the speed and cutting force to produce thin crystalline wafers while minimizing breakage. KAYEX CG 6000's slicing component employs a C-frame with either a mechanical or electrical drive for precise slicing and cutting. The slicing model is equipped with various quartz saws and c-frame cutters, allowing it to perform complex slicing, cutting, and chipping operations on crystalline material. The crystals can be precision cut and sliced into various shapes and sizes depending on the application. HAMCO CG 6000 equipment is a unique solution for crystal growth, sawing, and slicing applications. It provides a cost-effective, precise solution that produces superior crystal purity and low-angled crystal slices. The system is easy to use, with a user-friendly interface that allows users to accurately adjust the parameters for optimal crystal growth, sawing, and slicing operations.

There are no reviews yet