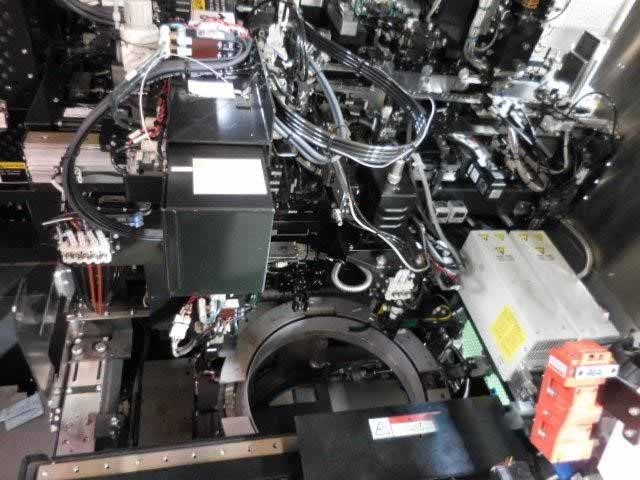

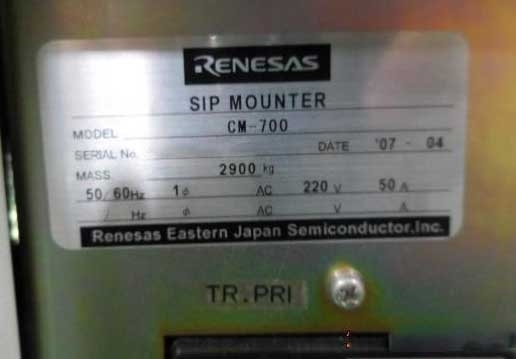

Used HITACHI / RENESAS CM 700 #9253790 for sale

URL successfully copied!

Tap to zoom

ID: 9253790

Vintage: 2007

SIP Mounter, 12"

Configuration:

Input station:

Magazine handling system

Lead frame / Substrate stacker

Interposer loading system

Interposer handling system

Pre bake unit: RT 300°C

Pre heat unit: RT 200°C

Die bonding system

Die lamination system

Output magazine handling system

Wafer handling system

Die pick and place system

Vision system

High speed bonding: 3600 UPH

Placement accuracy: XY < 38μM (3σ)

Mount method: Face down heat compression

Bond tool:

Temperature: Up to 400°C

Force: 7.8 to 147 N

Lamination tool

Temperature: Up to 400°C

Force: 19.6 to 490 N

2007 vintage.

HITACHI / RENESAS CM 700 die attach mechanical unit is a versatile and reliable die bonding robot with a die attach pick-up arm which works both with axial components and right angle connectors. This equipment can achieve high-speed dispensing for both non-pick-up and pick-up pin ID component installations as well as silent, beat-less flow die attach applications. Thanks to its advanced technology, HITACHI CM 700 prevents any potential die damage and increases the production output. RENESAS CM-700 uses the latest in-die attach technology, including a stationary jogger substrate table and a moving die attach arm. The stationary jogger substrate table is adjustable and helps in providing a clean field for component installation. It also features auto die placement and squeezing, and has the potential to produce component installation rates of up to 5000 parts per hour. This unit also provides a model-based setup procedure that can determine the optimal combination of die placings. The moving die attach arm can reach speeds of up to 2000mm/sec for precise installation of various components. It can precisely pick up and place components without causing damage. With its flexible and adjustable settings, it can produce precise die attach applications for any combination of component sizes, heights, and positions. With the addition of a die attach vision system, it can also perform non-destructive screening and inspection for advanced ID component installations. HITACHI / RENESAS CM-700 is designed with a user-friendly graphical interface, providing easy setup and operation, with minimal complexity and specialised training. This makes RENESAS CM 700 particularly suitable for high-volume, high-accuracy die attach applications. Additionally, this machine is designed with a robust and durable construction, with perforated sheet metal covers and steel frames for maximum protection against shocks and dust. These features ensure repeatable, reliable, and accurate systems throughout the lifecycle of each production line. Overall, CM 700 die attach mechanical unit is an innovative and advanced solution for numerous die attach applications. From non-pick-up to pick-up pin ID component installations, its advanced technology, user-friendly graphical interface, adjustable settings, and durable construction make it a suitable and reliable system for any production environment.

There are no reviews yet