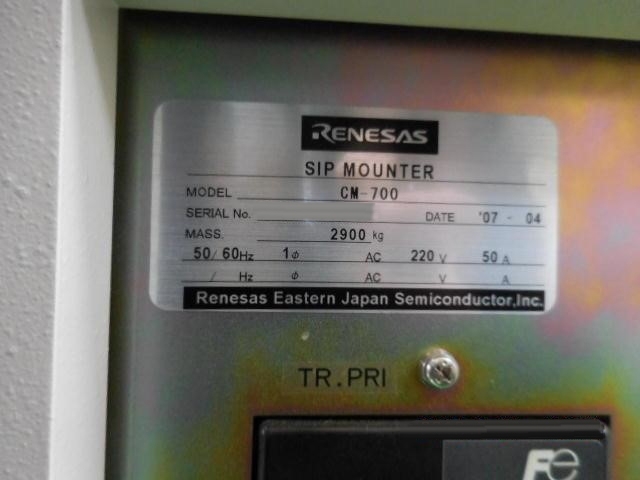

Used HITACHI / RENESAS CM 700 #9253793 for sale

URL successfully copied!

Tap to zoom

ID: 9253793

Wafer Size: 12"

Vintage: 2007

SIP Mounter, 12"

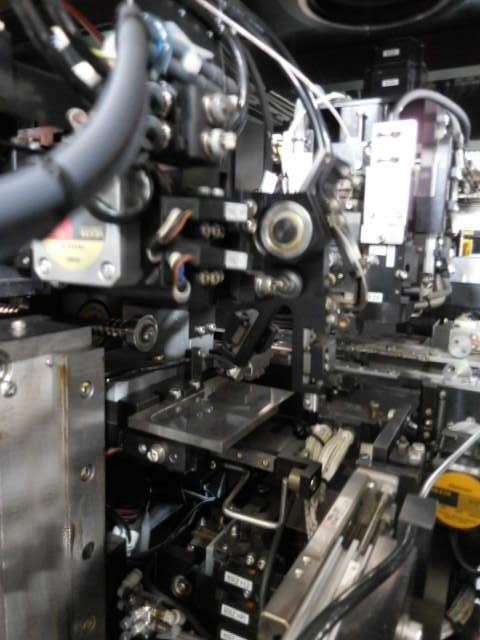

Input station:

Magazine handling system

Lead-frame / Substrate stacker

Interposer loading system

Interposer handling system

Pre-bake unit: RT~300°C

Pre-heat unit: RT~200°C

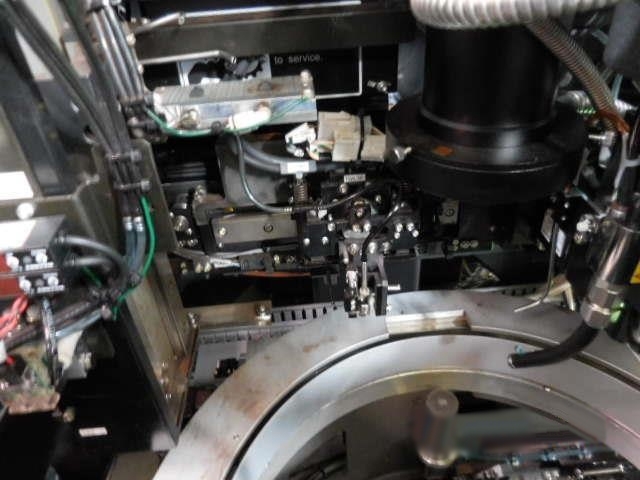

Die bonding system

Die lamination system

Output magazine handling system

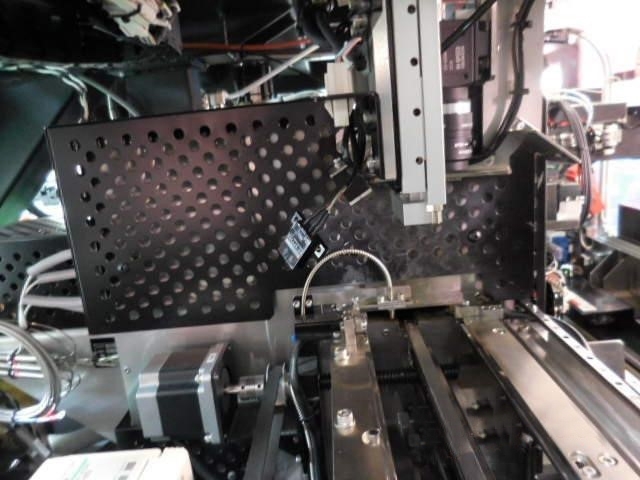

Wafer handling system

Die pick and place system

Vision system

High speed bonding: Up to 3600 UPH

Placement accuracy: XY < 38 μM (3σ)

Mount method: Face down and heat compression

Bond tool:

Temperature: Up to 400°C

Force: 7.8 to 147 N

Lamination tool:

Temperature: Up to 400°C

Force: 19.6 to 490 N

2007 vintage.

HITACHI / RENESAS CM 700 is a die attach machine designed to build highly efficient and low-cost components for a wide range of applications. Featuring advanced features such as fully automatic die attaching, integrated glue re-stocking equipment, and one-touch operation, this machine offers the ease of use, speed and accuracy needed for solderless interconnect assembly in a variety of demanding applications. HITACHI CM 700 is capable of die attaching with a precision of ± 30µm, making it ideal for highly efficient and low-cost components. Its integrated glue re-stocking system uses specially formulated adhesive to promote strong bonding between the die and substrate and ensure die assembly is secure and reliable. The machine incorporates field programmable logic control (PLC), providing easy-to-use, one-touch operation and flexible programming. The user-friendly touch panel display provides a visual guide to the operation and layout of the machine. RENESAS CM-700 supports various die packages, including Small Outline Package (SOP) and Quad Flat No-Lead (QFN). It can handle dies from 1- to 10-mm2 in size, with a daisy-chain operation allowing multiple dies to be attached simultaneously. With its linear motor technology, the machine features fast attachment speeds, making it a reliable and efficient solution for high-volume production. HITACHI / RENESAS CM-700 is equipped with multiple safety features to protect both the machine operators and the delicate die parts. An adjustable optical safety shield protects against contamination and ensures secure die handling. In addition, the machine's auto-shutoff function shuts down the entire unit if an obstruction or other object blocks the die attach cycle for added safety. CM-700 is a powerful die attach machine offering the efficient and reliable automated assembly of highly accurate and low-cost components. Its advanced features, such as one-touch operation, integrated glue re-stocking machine, and field programmable logic control make this highly capable machine an ideal solution for demanding production environments.

There are no reviews yet