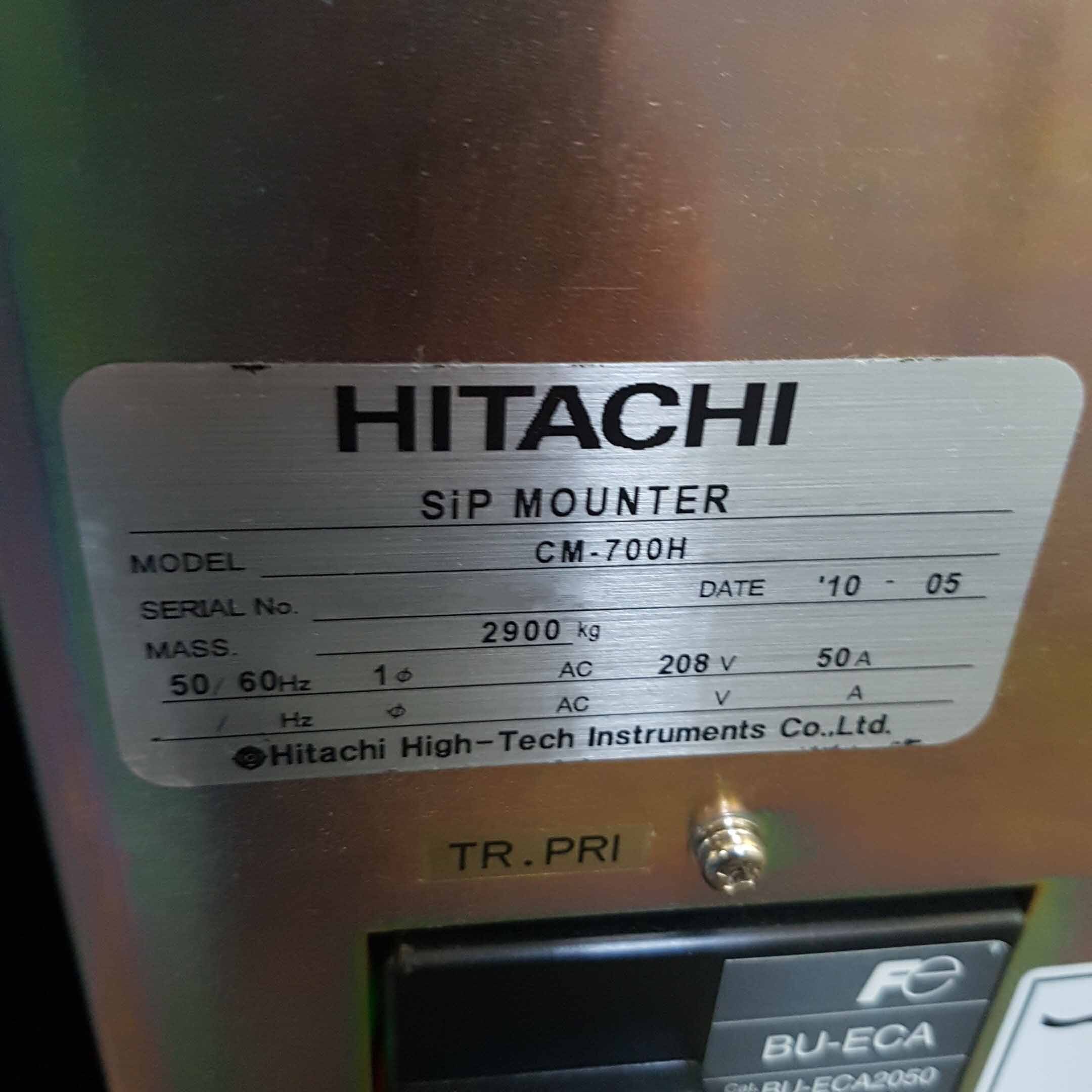

Used HITACHI / RENESAS CM 700H #9366142 for sale

URL successfully copied!

Tap to zoom

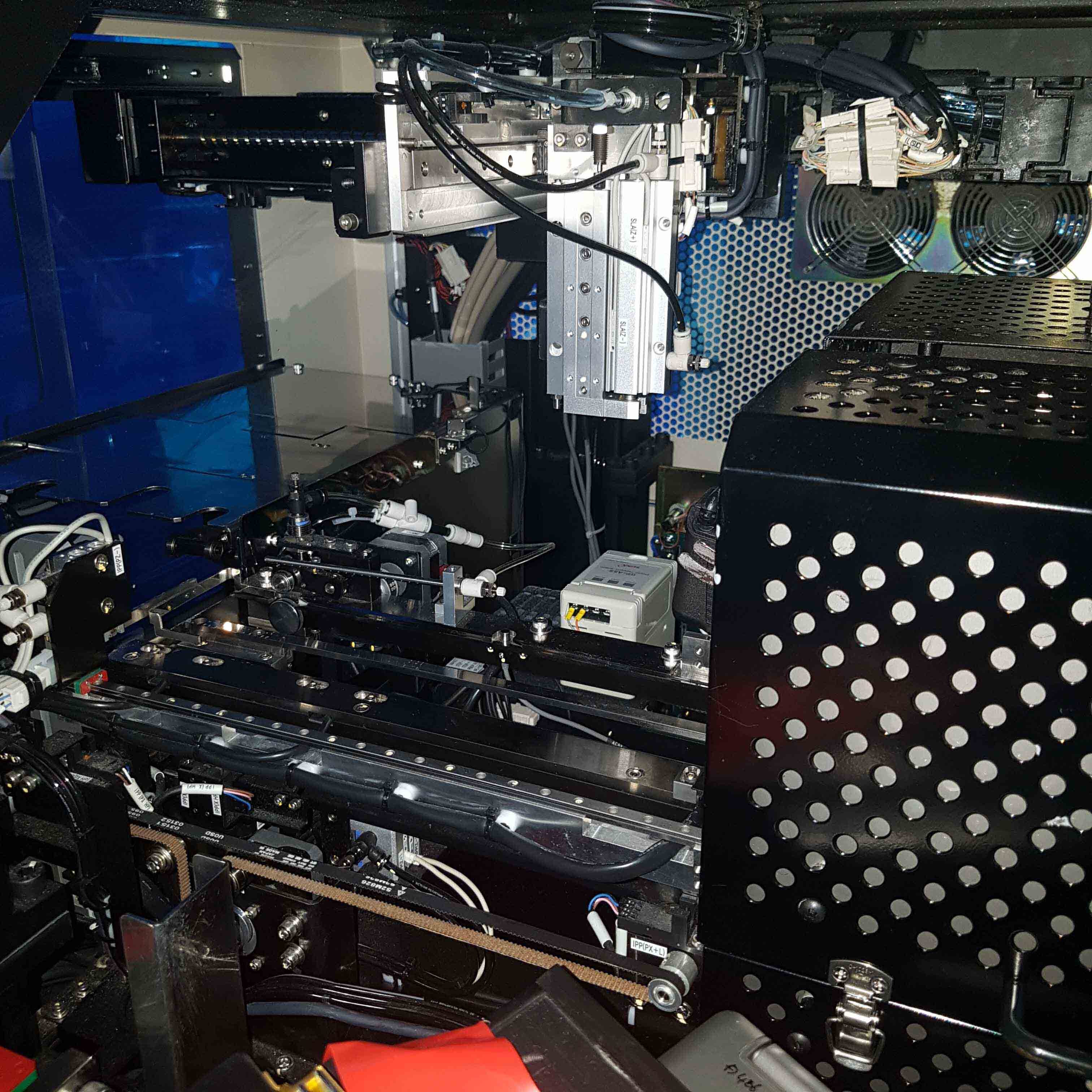

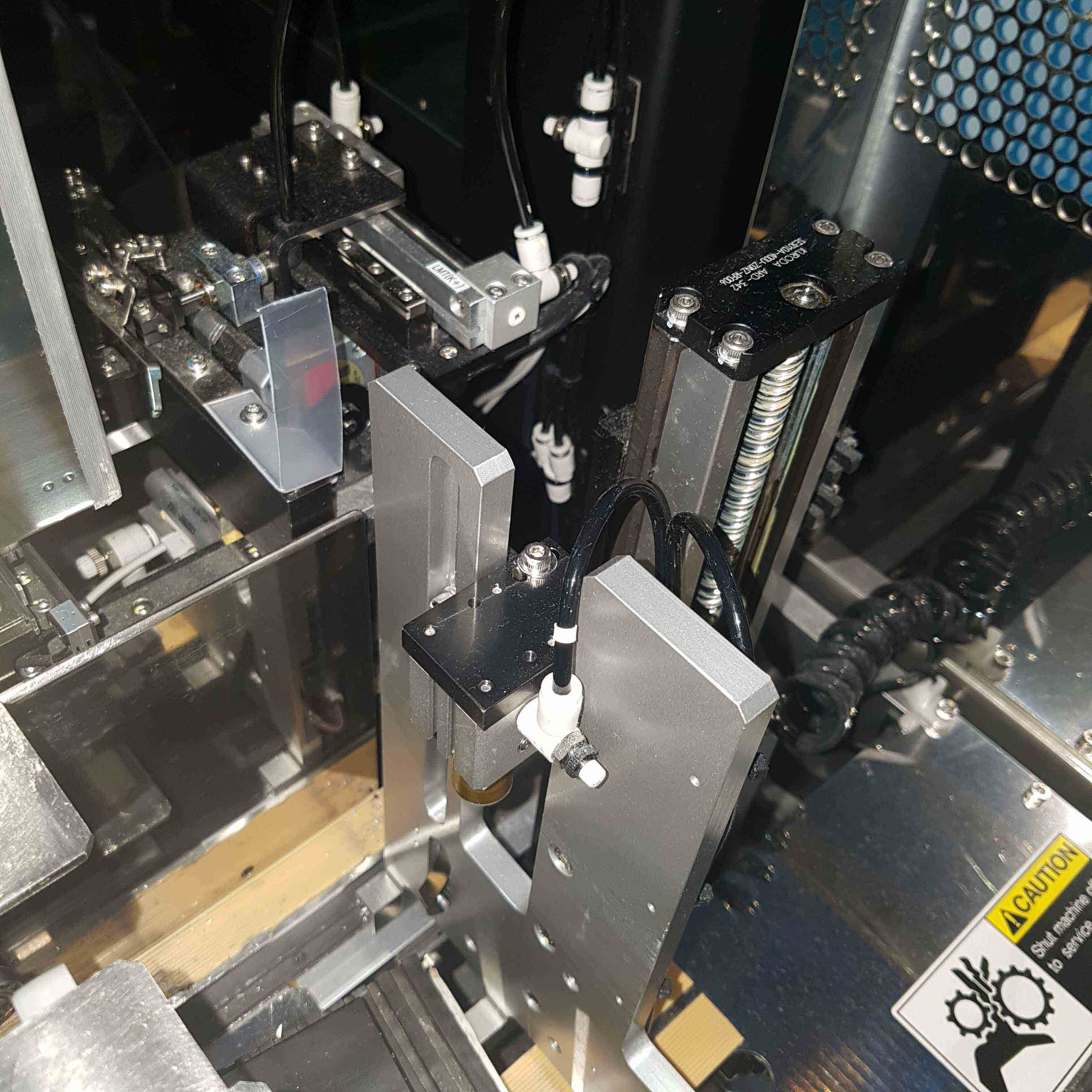

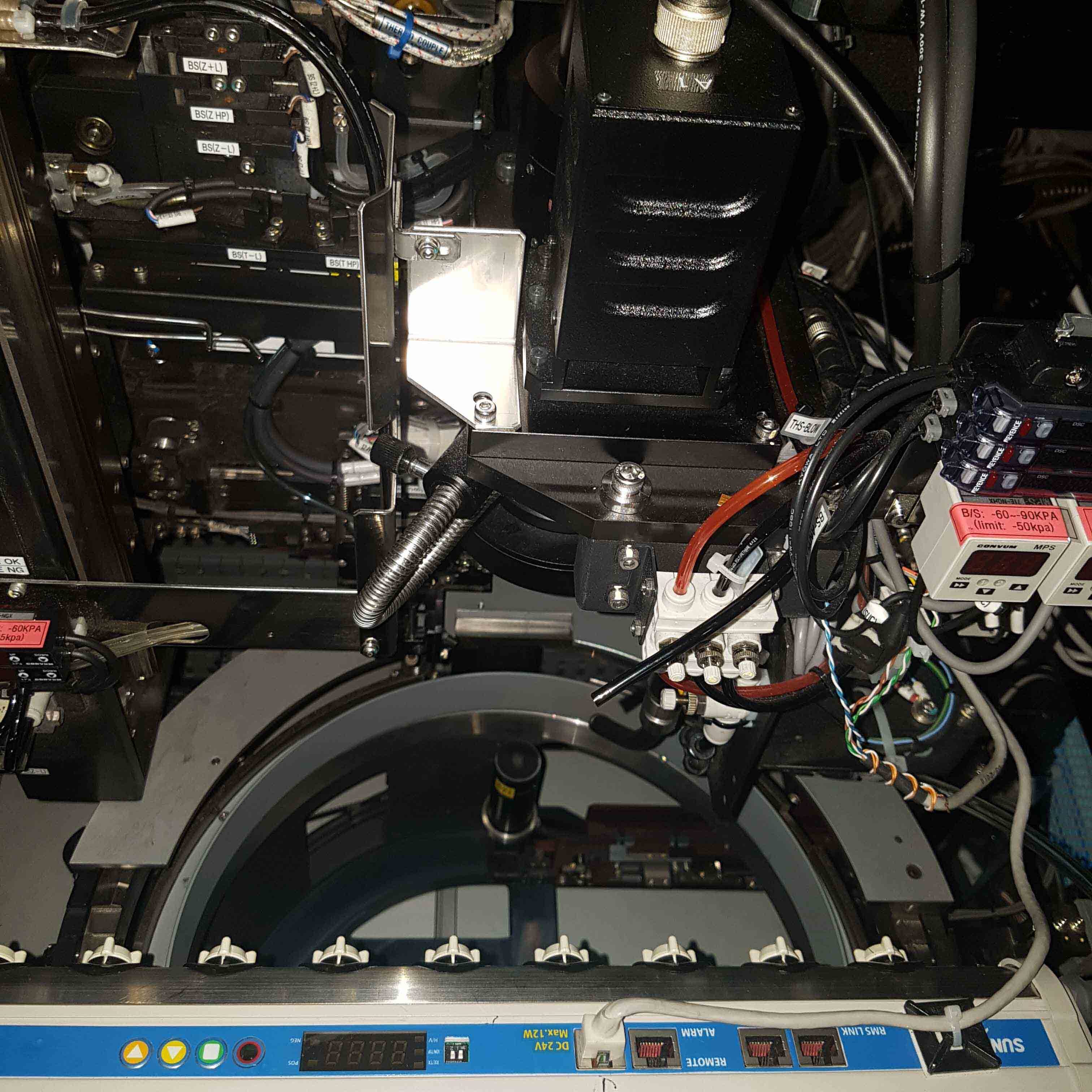

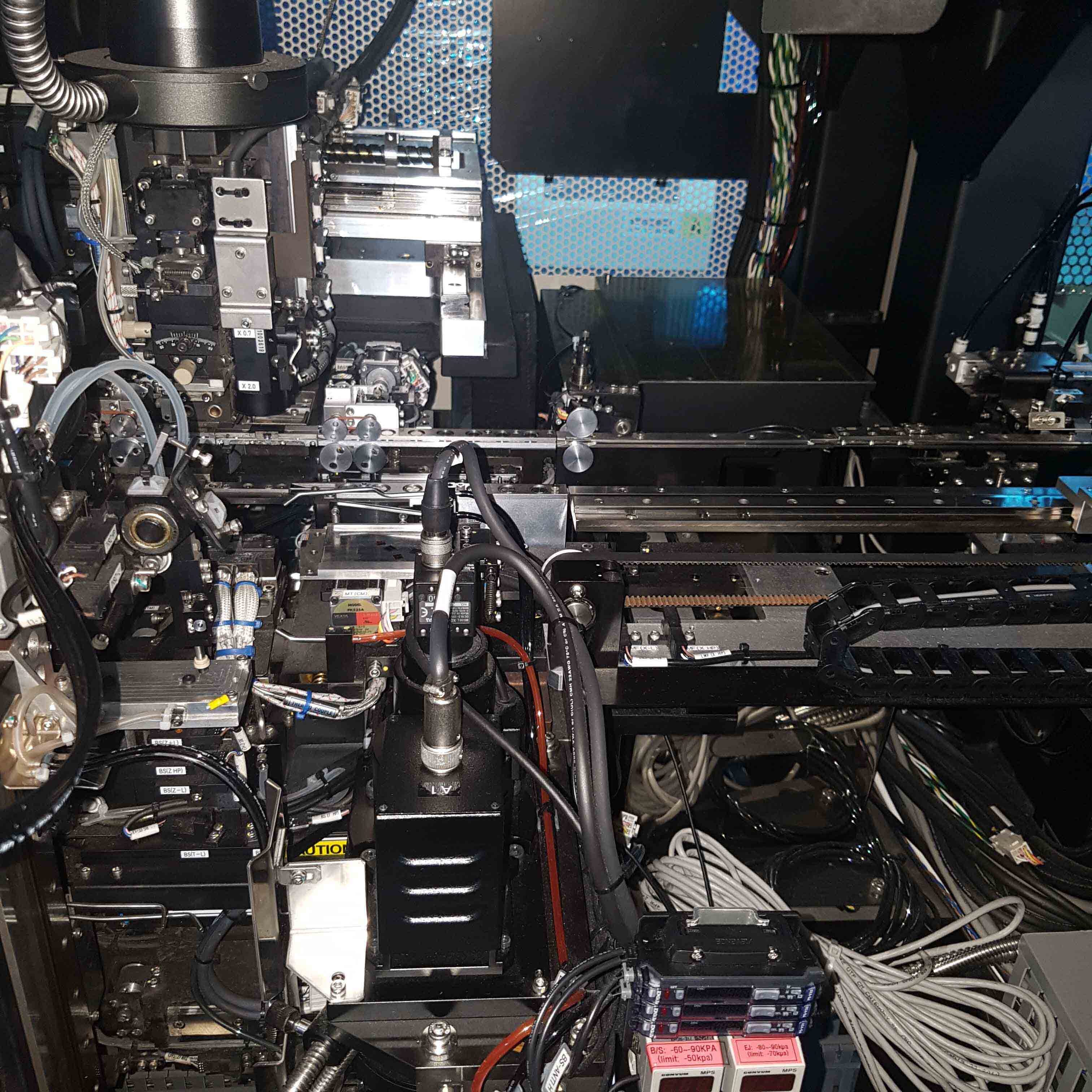

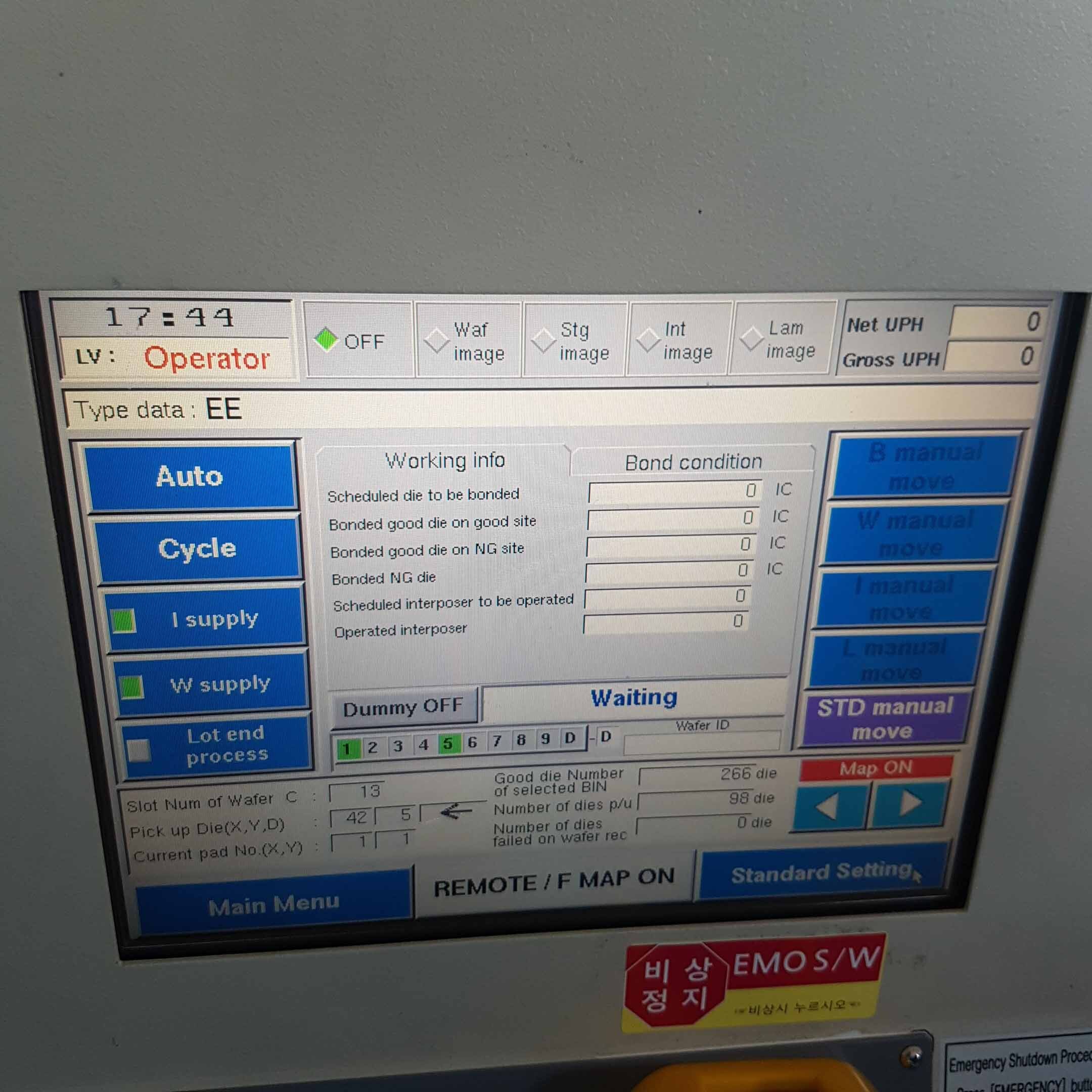

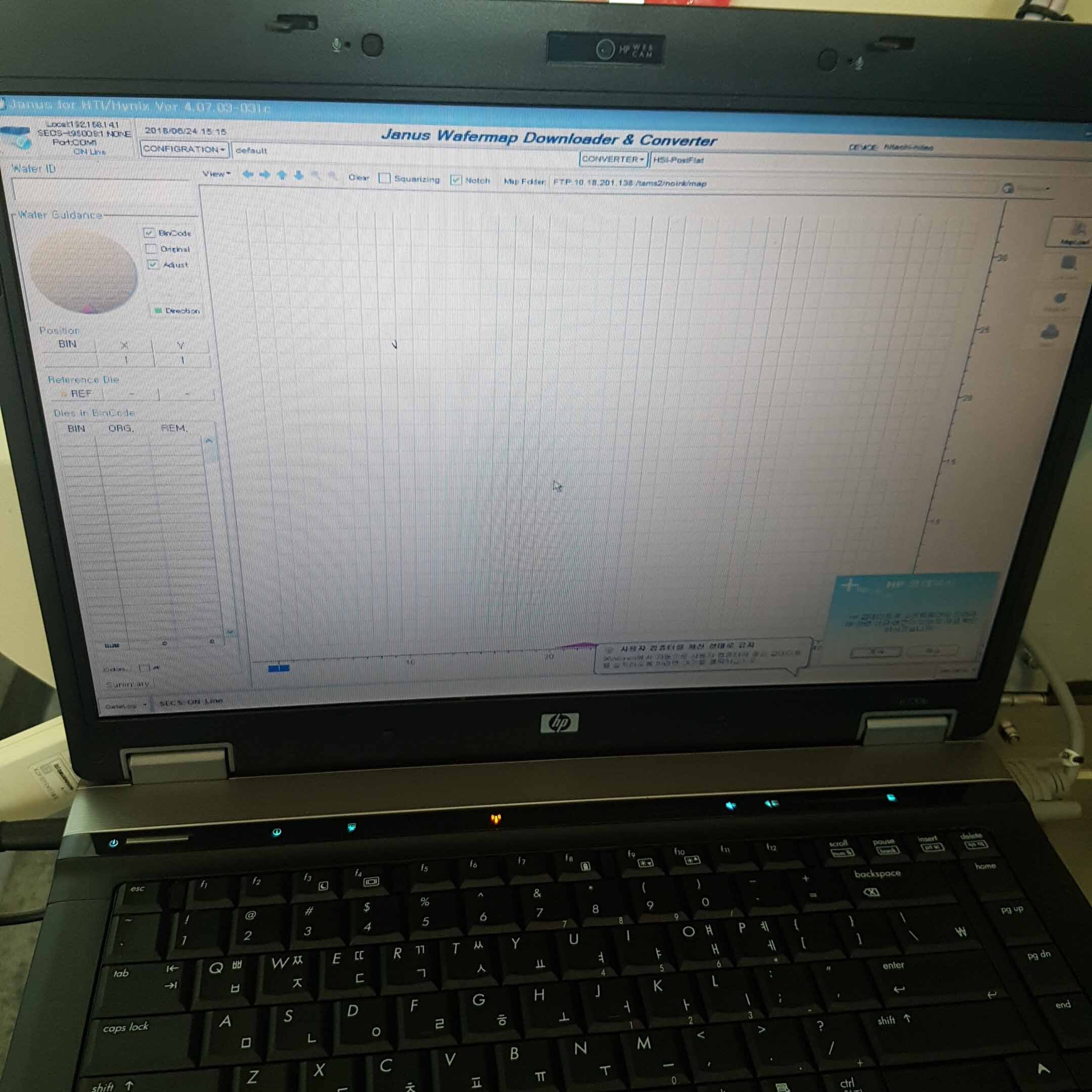

HITACHI / RENESAS CM 700H is a state of the art die attacher that is designed for efficient operation. It features a high speed placement of up to 3000 pieces per hour with highly accurate die positioning and high throughput production rates for larger orders. The die attacher has a compact body with an intuitive user-friendly interface, allowing for easy programming and troubleshooting. It also features a pick-and-place head that offers excellent stability and manoeuvrability, allowing for precise die placement and adjustment. The tool makes use of advanced motion control technology to insure faster and more accurate execution of the commands, resulting in higher precision and output with less waste of materials. HITACHI CM 700H also features a load cell which allows for accuracy in the placement of the dies. This is especially beneficial when precise positioning is important. The robust construction of the tool enables it to handle large volumes of die placement tasks in a short period. The load cell can be programmed to detect the weight of the die, resulting in more accurate die placement with fewer rejects. RENESAS CM 700H also features a vision system which assists in the placement process. This includes image acquisition and processing, as well as edge detection for more precise placement of the dies. To further add to its accuracy, CM 700H utilizes a laser detection system to detect the edges of the dies for an even more accurate positioning. Finally, the user-friendly programming software allows users to easily tweak settings to their needs. From adjustable parameters, such as temperature and heating/cooling times to selecting optimal nozzle size, nozzle type and die placement speed, users have the ability to tailor the system to their requirements. In conclusion, HITACHI / RENESAS CM 700H is a high-end, high-performance die attacher that boasts superior throughput speeds, robust stability and precise positioning that yield numerous benefits for both production and the environment. As a result, this state-of-the-art die attcher is ideal for research and development applications and for mass production of custom parts and components.

There are no reviews yet