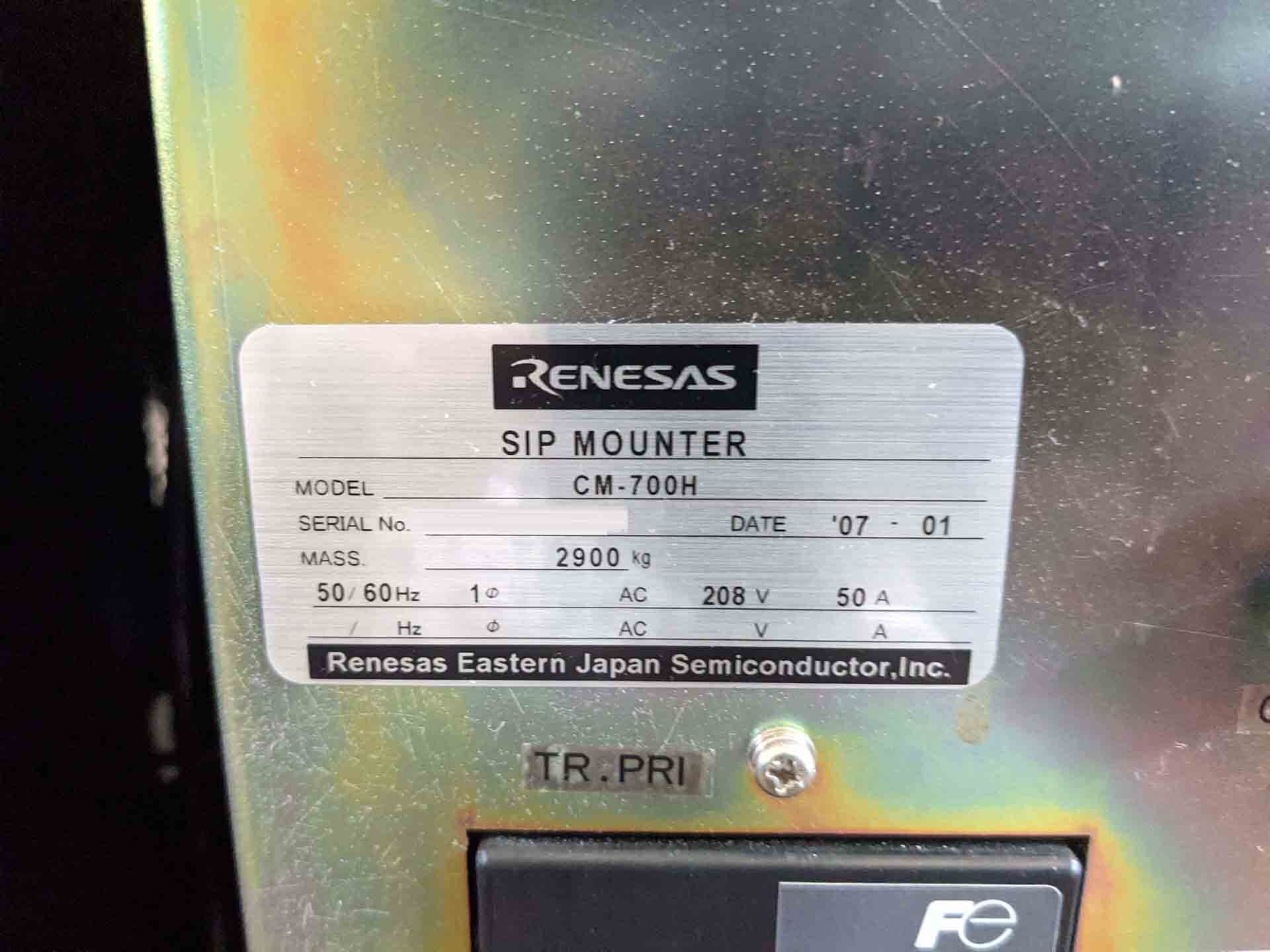

Used HITACHI / RENESAS CM 700H #9399513 for sale

URL successfully copied!

Tap to zoom

HITACHI / RENESAS CM 700H is a state-of-the-art die attacher designed for efficient semiconductor assembly. The machine is capable of accurately placing and attaching small dies onto substrates with extreme precision in a fast and reliable manner. HITACHI CM 700H utilizes precision motion and vision control technology that allows it to accurately position and pick up die from a height of 0.2mm and place the die onto various transfer surfaces with an accuracy of 0.02mm. RENESAS CM 700H is also capable of handling a wide variety of die sizes and shapes. It can process die sizes ranging from 0.2mm square to 12mm square, and can also process different die shapes including small squares, rectangles, circles and ellipses. CM 700H comes equipped with an auto-adjustable precision optical alignment system which uses a proprietary image recognition algorithm to automatically detect various defects within the die, including out-of-spec die shape, orientation, and warpage. This system helps to achieve the highest possible yields when using HITACHI / RENESAS CM 700H. Its auto-placement software allows HITACHI CM 700H to place and attach components without human intervention. The software is capable of automatically locating and attaching die in any order and pattern, eliminating the need for tedious manual labor during the assembly process. RENESAS CM 700H is capable of operating in a variety of production environments, ranging from low volume to high-volume production scenarios. It is designed to provide superior performance with high speed, stability and reliability. Its built-in safety functions also enable it to operate safely in a fast, high-volume production line. In addition to its high speed, CM 700H is energy-efficient and uses minimal energy, helping to reduce overall costs. For added convenience, the machine features an intuitive touchscreen HMI interface that allows users to easily adjust and monitor the machine's settings. It also includes a built-in system for monitoring and controlling the quality of attached dies, enabling users to quickly diagnose and rectify product defects. Over time, the machine can store data about the product history, including defects and performance-related parameters for further analysis. Additionally, the machine can be integrated into existing networks for shared use with other machines or connected to an external computer to easily download and transfer data. HITACHI / RENESAS CM 700H is an impressive die attacher that effectively combines precision motion control, advanced vision and auto-placement software to achieve superior die assembly and attach yields. It is a robust and reliable machine that is capable of handling a wide variety of die sizes and shapes, and is suitable for any type of production environment.

There are no reviews yet