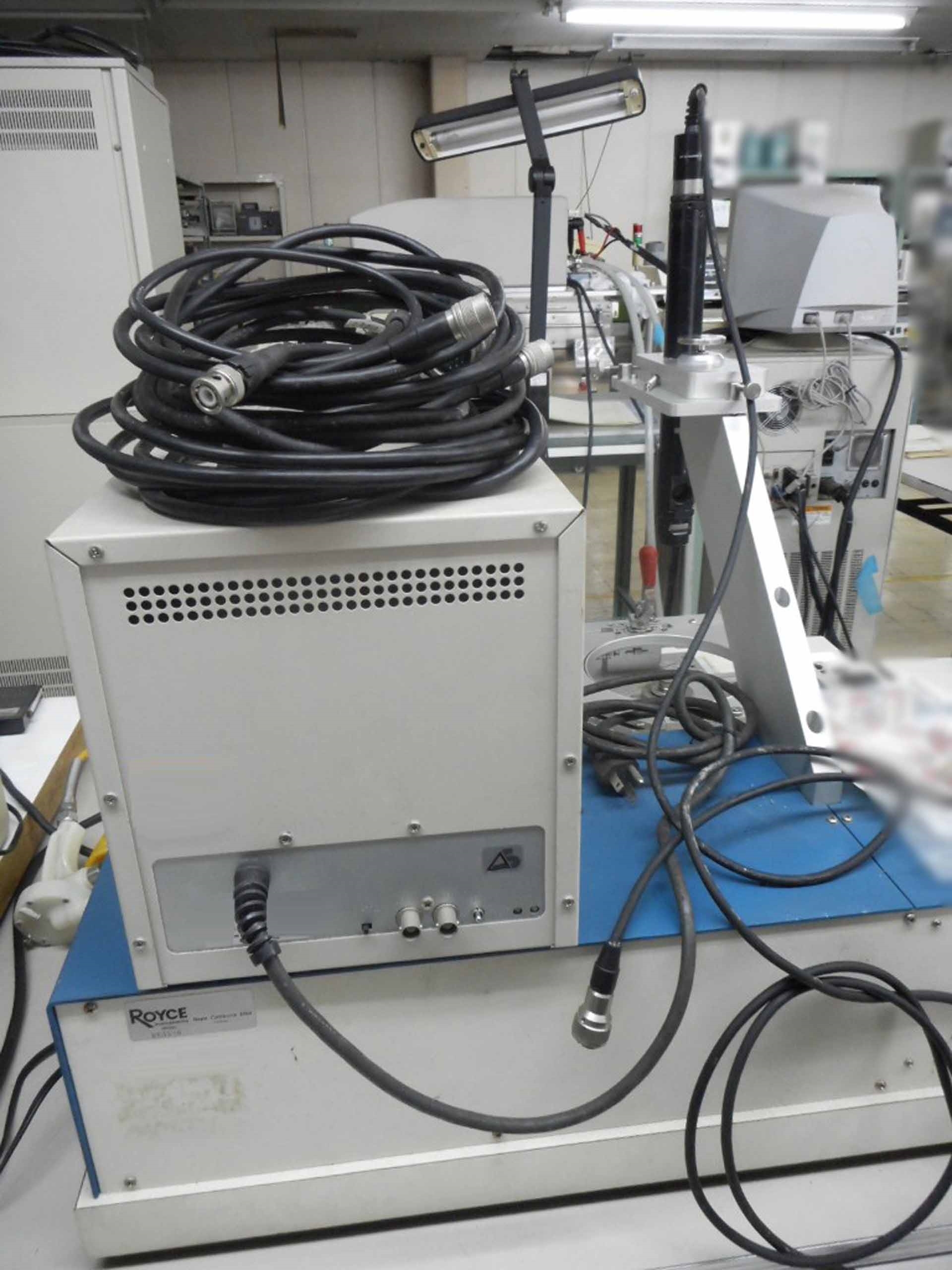

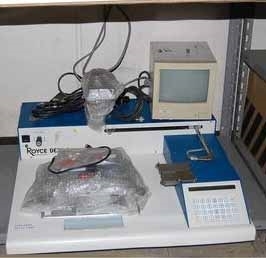

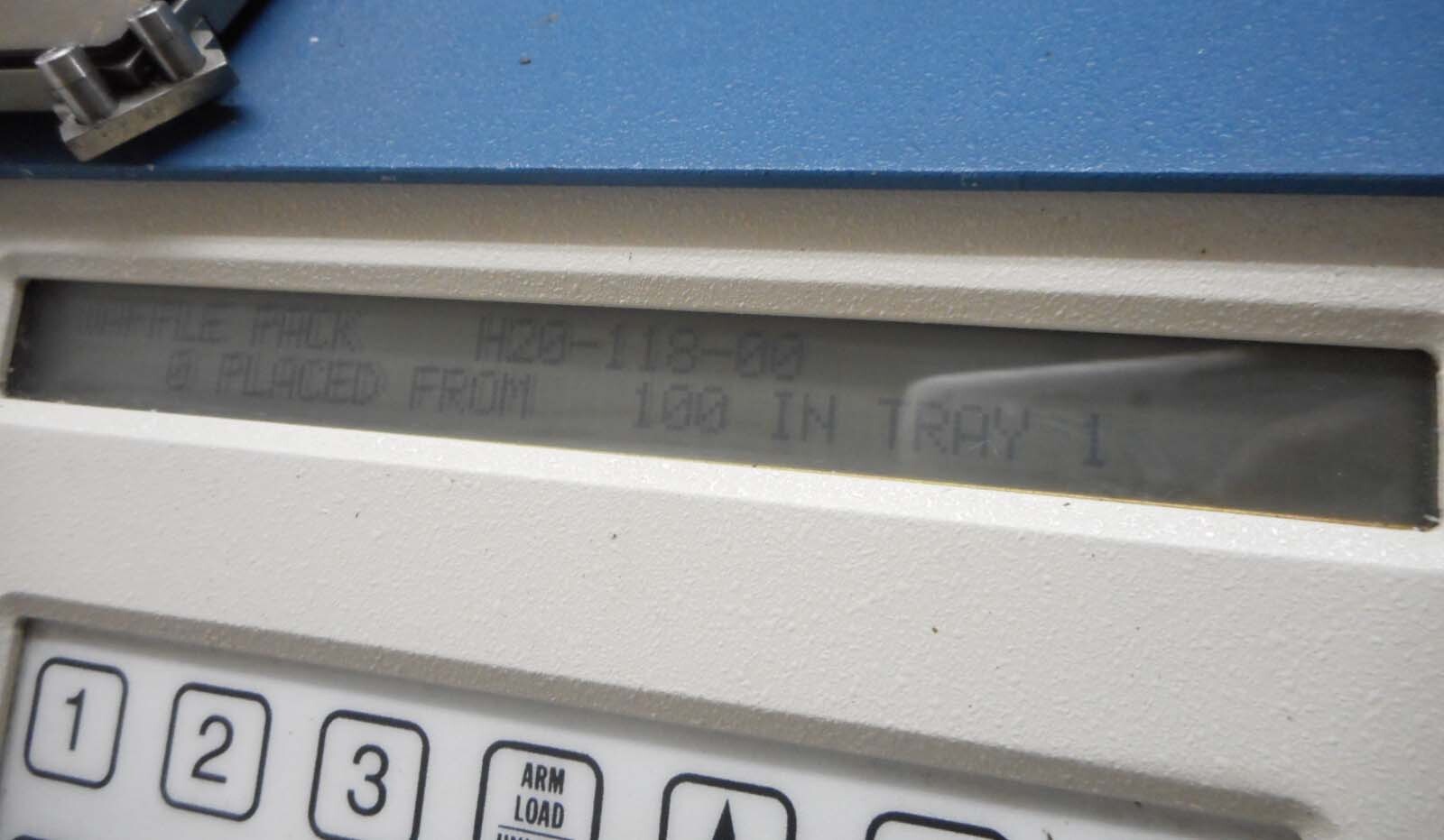

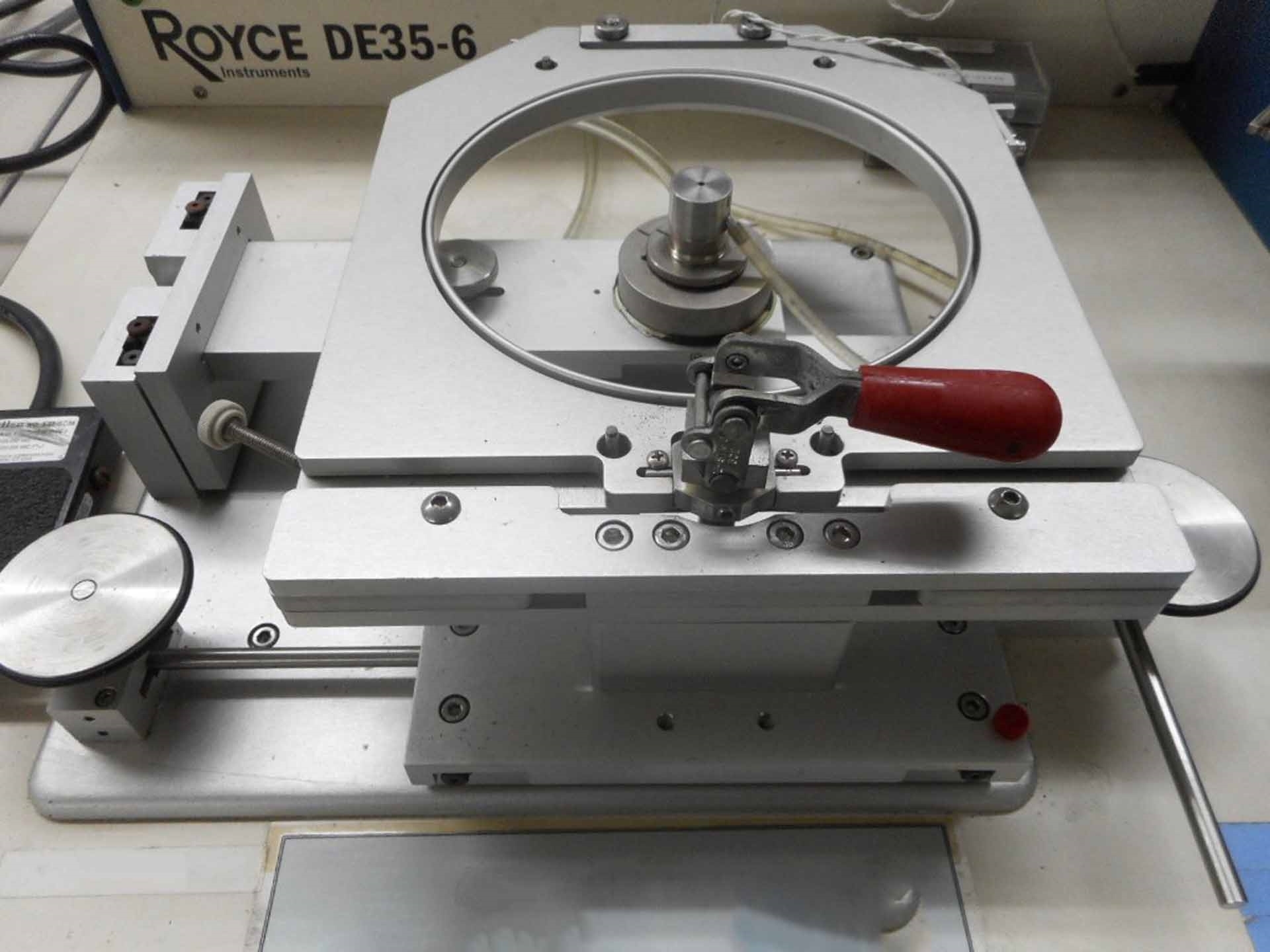

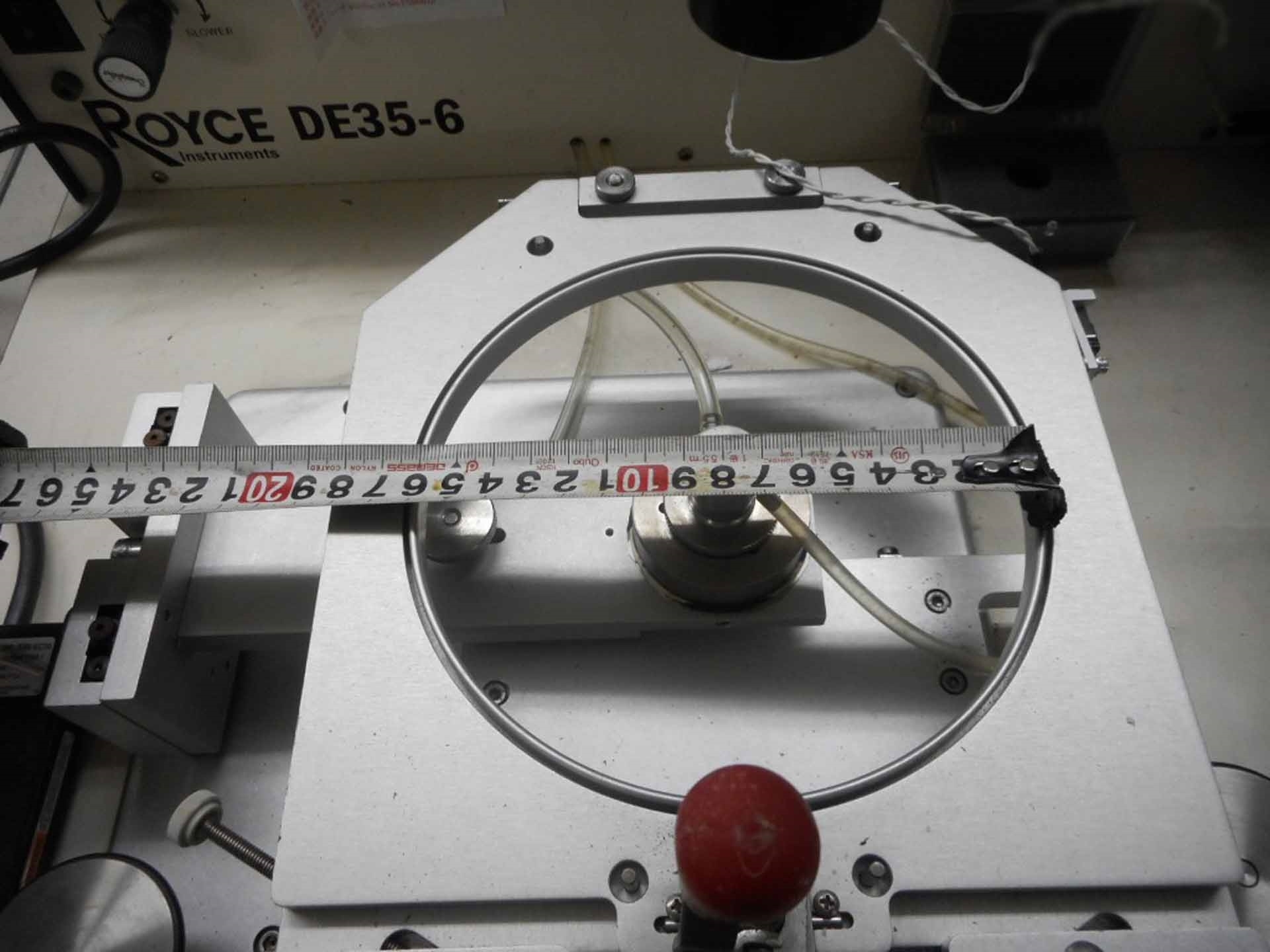

Used ROYCE DE 35-6 #9118143 for sale

URL successfully copied!

Tap to zoom

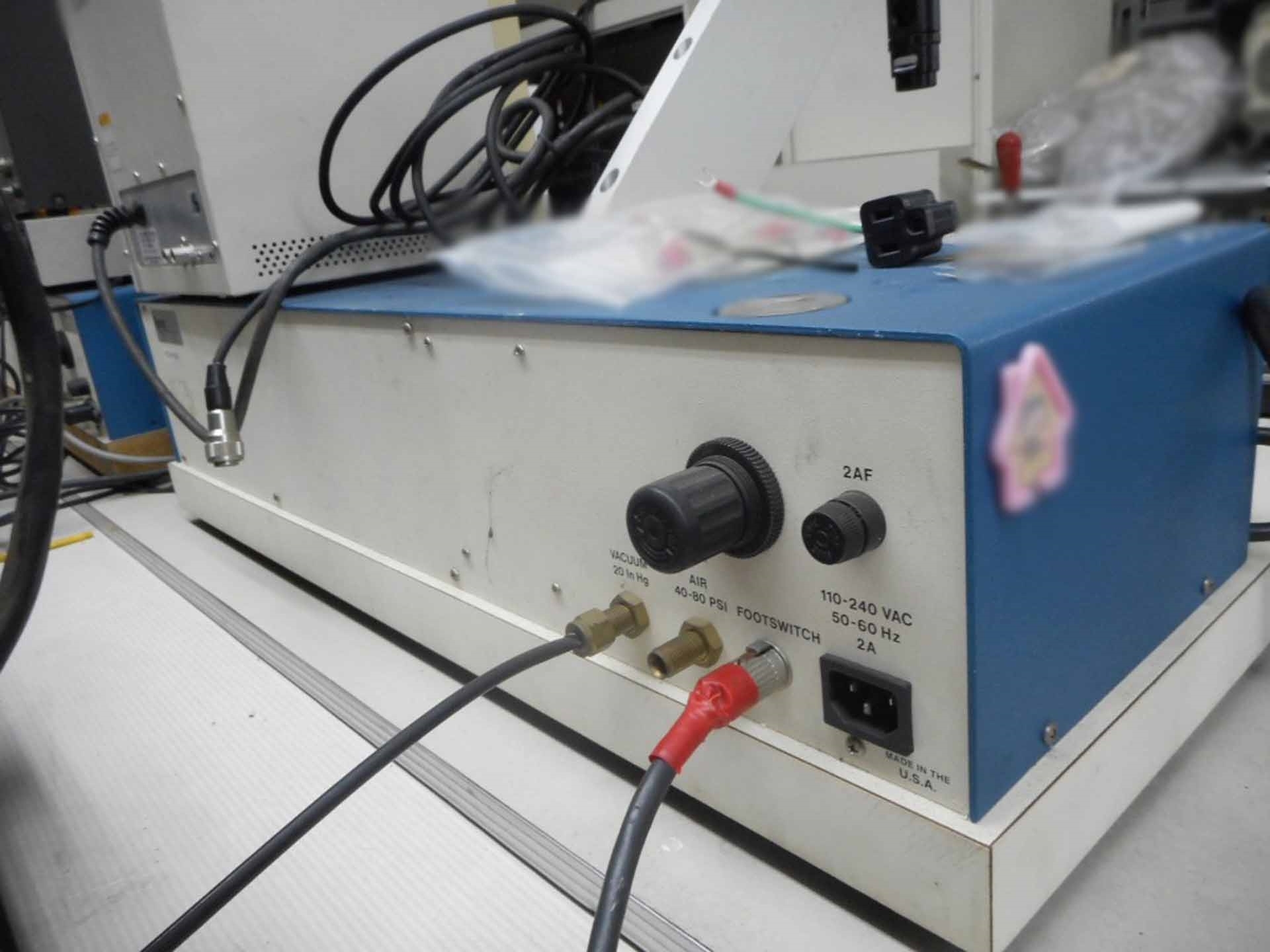

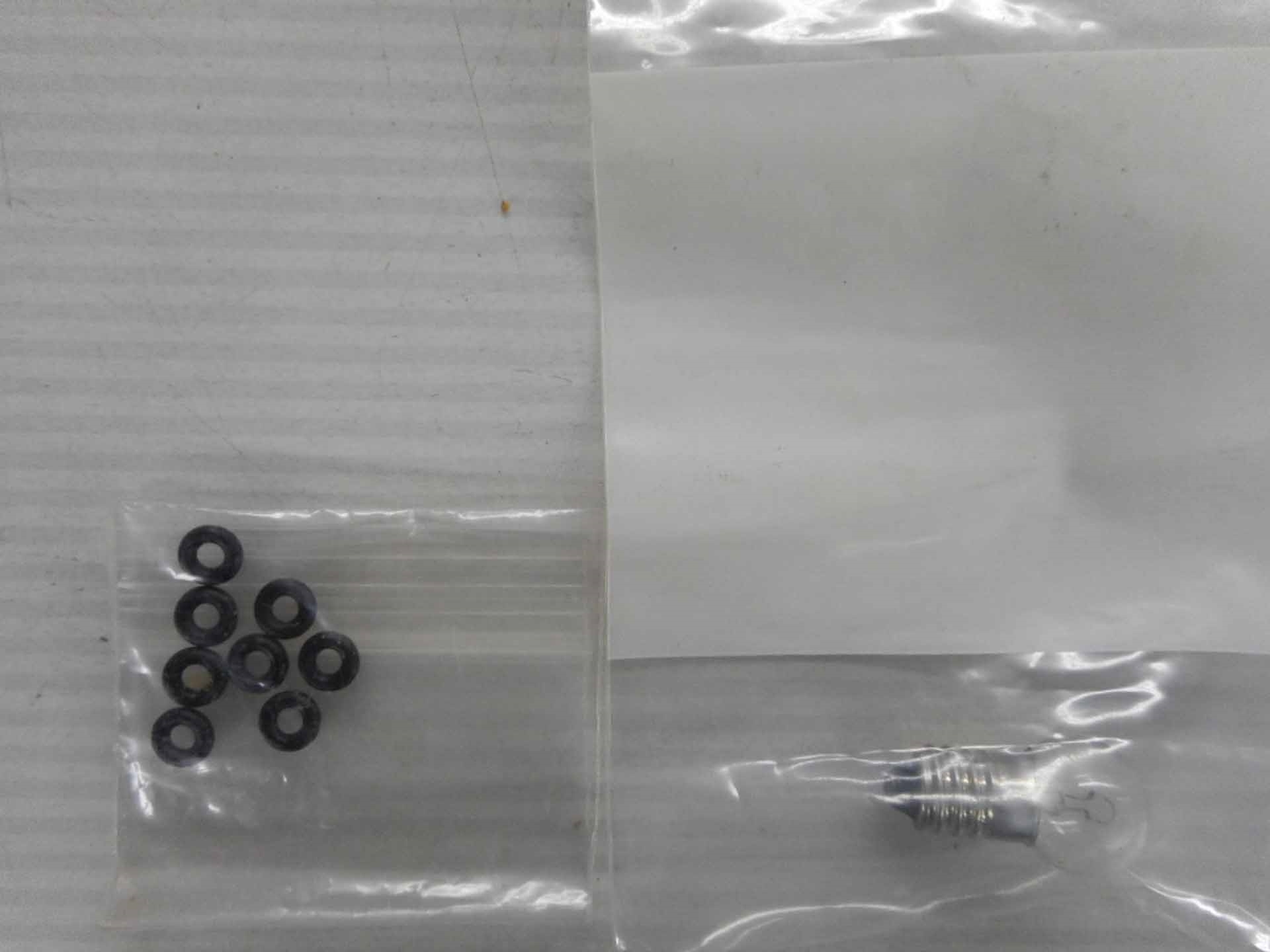

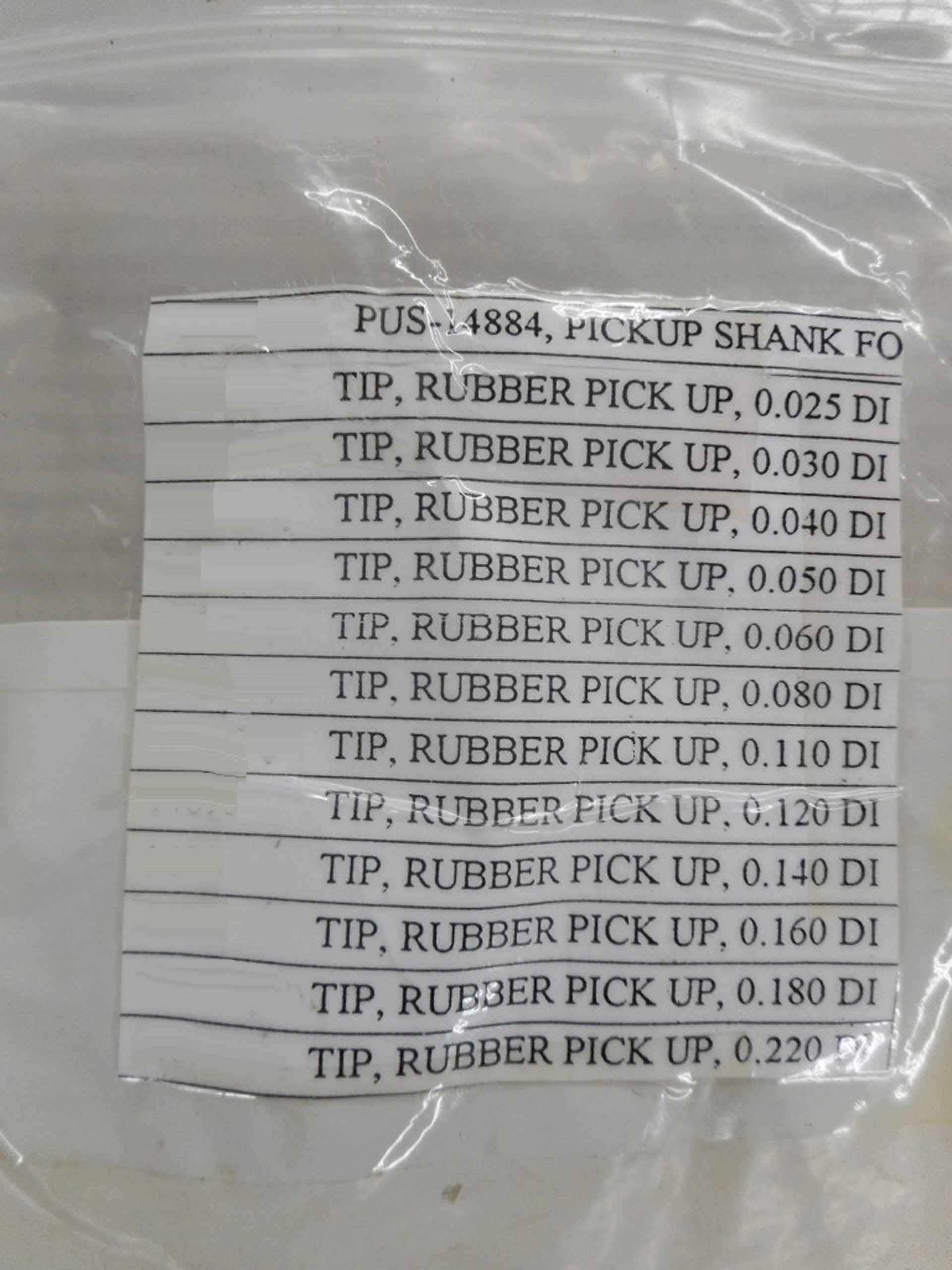

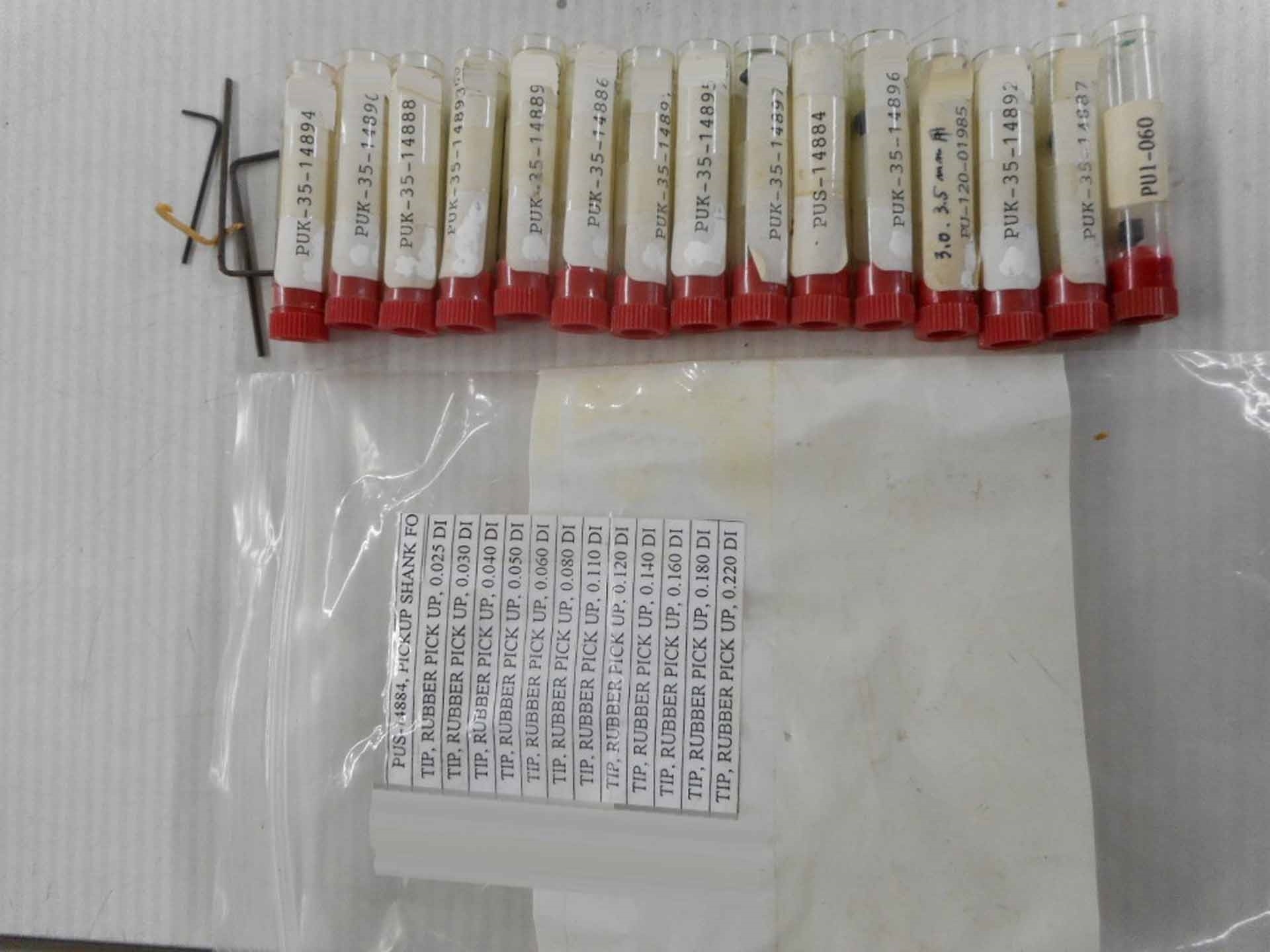

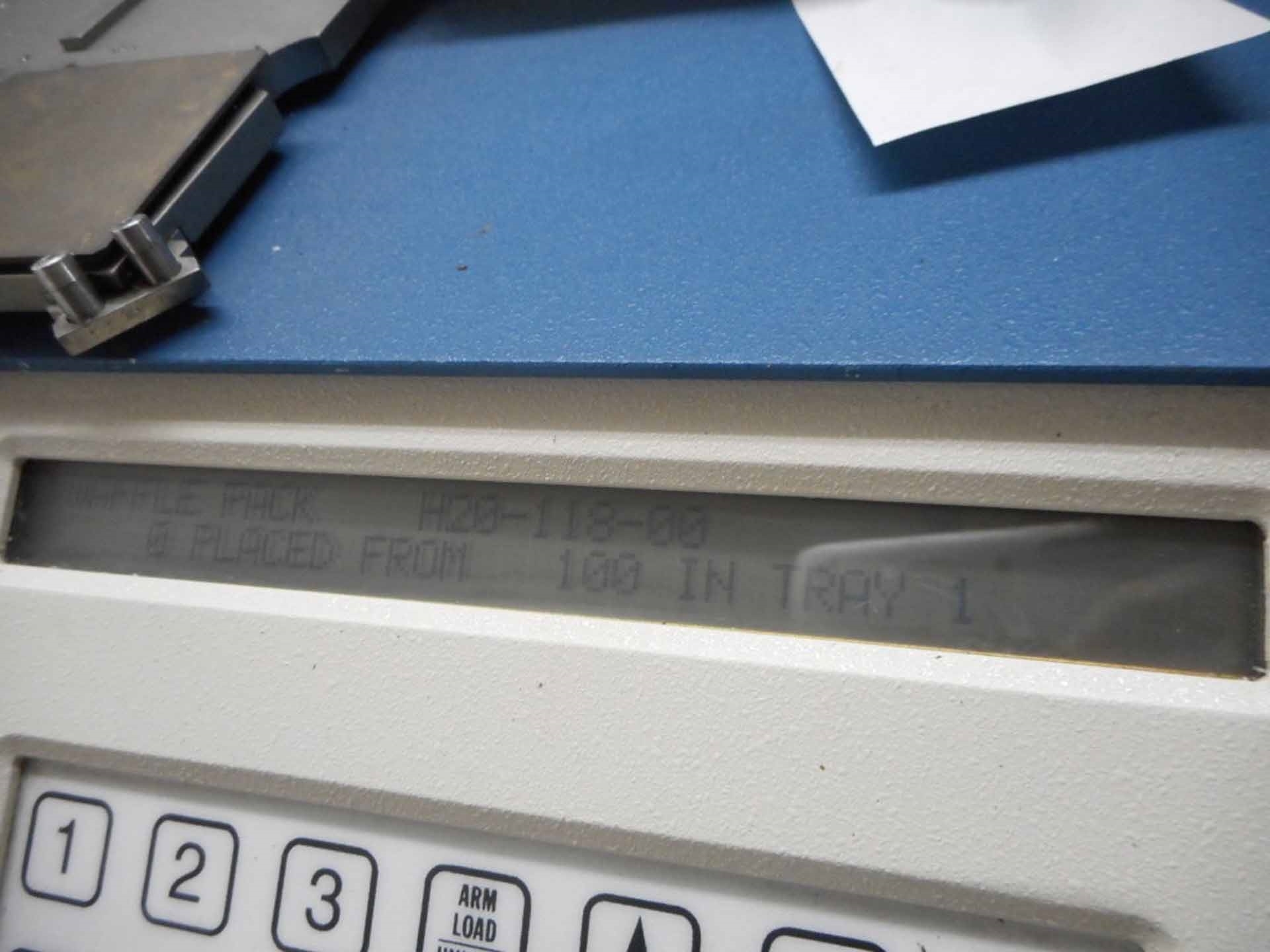

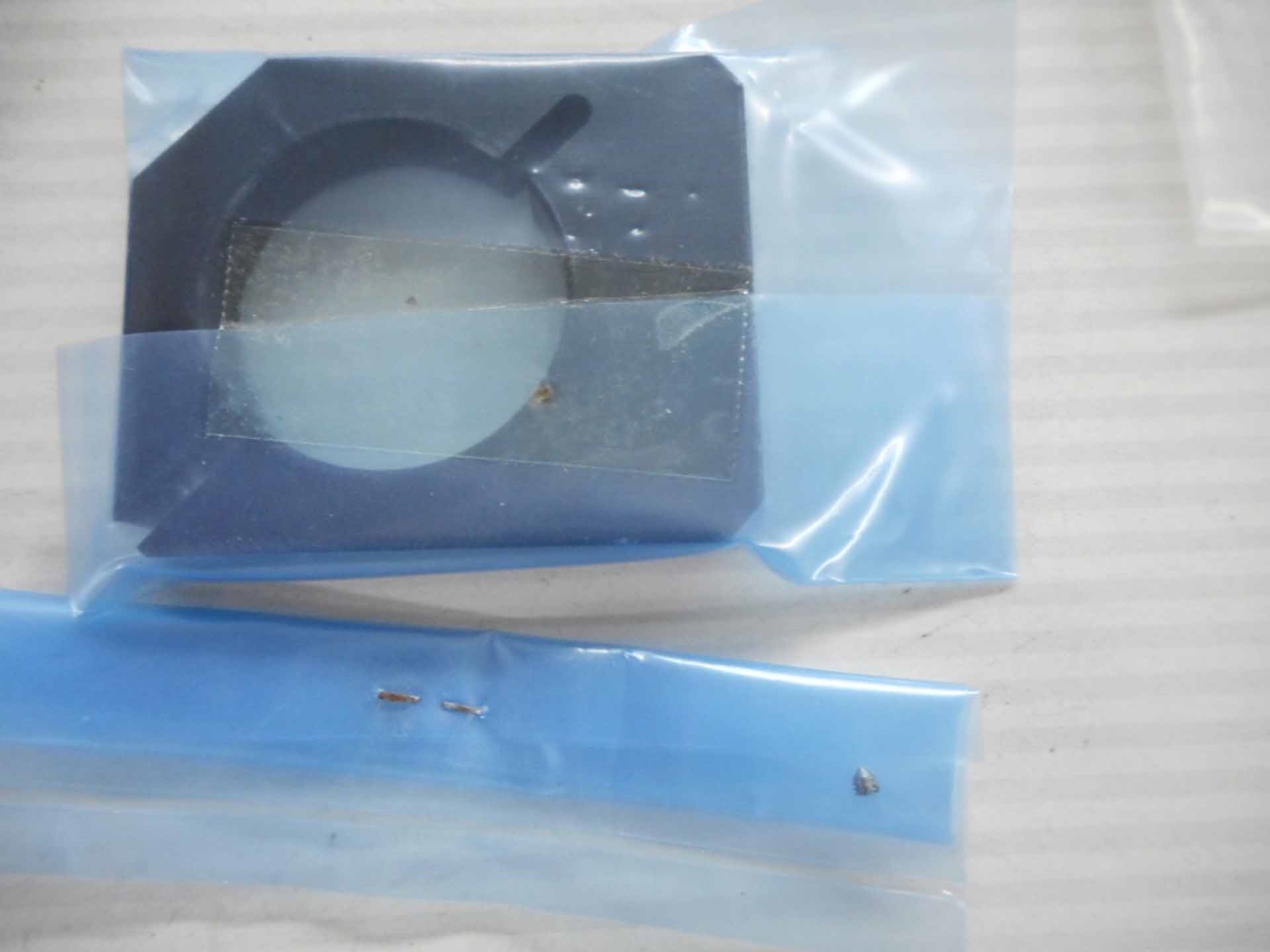

ROYCE DE 35-6 is a die attach machine that is designed to apply precision solder joints to die on ceramic substrates, even at the high speed assembly. This machine is capable of creating superior quality connections with high accuracy and repeatability. It is a fully automated system that is equipped with a 6-axis robot that is capable of performing all of the necessary motion functions, from placement to inspection. The robot arm is capable of moving in three planes, including up/down, side to side, and in the direction of the die. The arm is equipped with a force sensing device to ensure that the solder joints are applied with a fixed pressure. The machine also includes an advanced image recognition system that can detect the orientations of the die and adjust the placement accordingly. The die placement accuracy is within 8 microns, which is within industry standards. The machine is equipped with a modular motion controller, which is capable of controlling up to four pick and place motion axes as well as the vibration and rotation functions of the robot. The vibration functions allows for precise placement of the solder joint and the rotation function provides a way to rotate the substrate relative to the die, allowing for greater freedom in product design. The machine also includes a precision vacuum system which is used to attach the die and substrate. ROYCE DE35-6 is designed for high speed assembly of components on ceramic substrates. The machine is capable of producing high quality solder joints at a rate of up to 3000 joints per hour. The machine is also equipped with automatic self-adjustment and calibration features that ensure consistent and repeatable production operation. The machine is designed for use in high-volume production environments and is backed with a full range of after-sales service and support.

There are no reviews yet