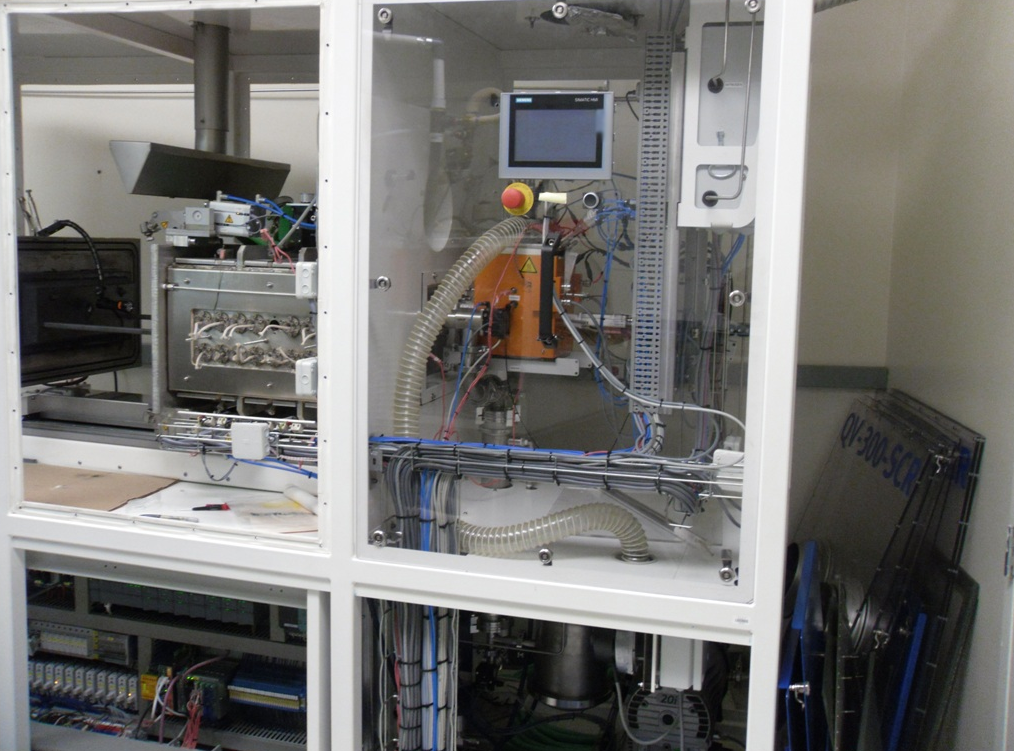

Used ELECTRON THERMAL PROCESSING EQUIPMENT / ETPE QV-300-SCR #9089376 for sale

URL successfully copied!

Tap to zoom

ID: 9089376

Wafer Size: 12"

Vintage: 2013

Diffusion furnace, up to 12"

R&D scale tool with control over heating, atmosphere, pressure and vapor diffusion

Previously used for Se introduction, but evaporator re-configuration is possible

Uses 18 quartz IR resistance heaters

Temperature: 300 °C to 650 °C

Siemens and Eurotherm control systems

Custom vented glove box cabinet with an ante-chamber and all electronics and control systems housed within

2013 vintage.

ELECTRON THERMAL PROCESSING EQUIPMENT / ETPE QV-300-SCR (Evolutionary Thermal Processing Equipment) is a diffusion furnace & accessorie equipment for annealing, sealing, and sintering processes. This system is capable of performing a variety of complex thermal processes in a closed environment, and offers an unprecedented degree of control over the heat transfer processes. This unit can achieve optimal substrate process temperatures up to 1320°C. The diffusion furnace supplies high temperatures and fast processing times that are useful in many industrial applications. ETPE QV-300-SCR uses a combination of resistive heating elements and convection heat transfer to provide the necessary heat transfer for sublimation, annealing, sealing, and sintering processes. This machine also incorporates a quartz convection tube for uniform temperature distribution within the furnace. The integral graphite heating elements contain multi-layer coils of high-temperature resistance wire that provide the best in-process temperature control. These heating elements are resistive in nature, preventing thermal shock to the sample material and providing uniform heating of the sample material. Wide-range variable speed centrifugal blowers are used for uniform heat transfer. The anvil assemblies located inside the chamber of ELECTRON THERMAL PROCESSING EQUIPMENT QV-300-SCR are composed of alloyed steels and stainless steels, providing superior strength and corrosion resistance. The chamber lid of the tool is designed to provide easy access for maintenance. QV-300-SCR also includes an emergency stop button, which allows for quick shut down in the event of an emergency. The advanced air temperature control asset of ELECTRON THERMAL PROCESSING EQUIPMENT / ETPE QV-300-SCR ensures that the correct temperature is achieved throughout the heating process. Additionally, the level of oxygen in the heater can be adjusted for optimum heating conditions. The model also includes a computersoftware for setting and monitoring temperatures, as well as recording and storing all data. Overall, ETPE QV-300-SCR is a reliable and advanced diffusion furnace & accessorie equipment that can be used in many industrial applications, such as annealing, sealing, and sintering processes. This system provides a host of features and benefits, including easy access for maintenance, computer-controlled temperatures, excellent temperature control, and corrosion resistant anvil assemblies.

There are no reviews yet