Used HITACHI / KOKUSAI DD-833V #9238011 for sale

URL successfully copied!

Tap to zoom

ID: 9238011

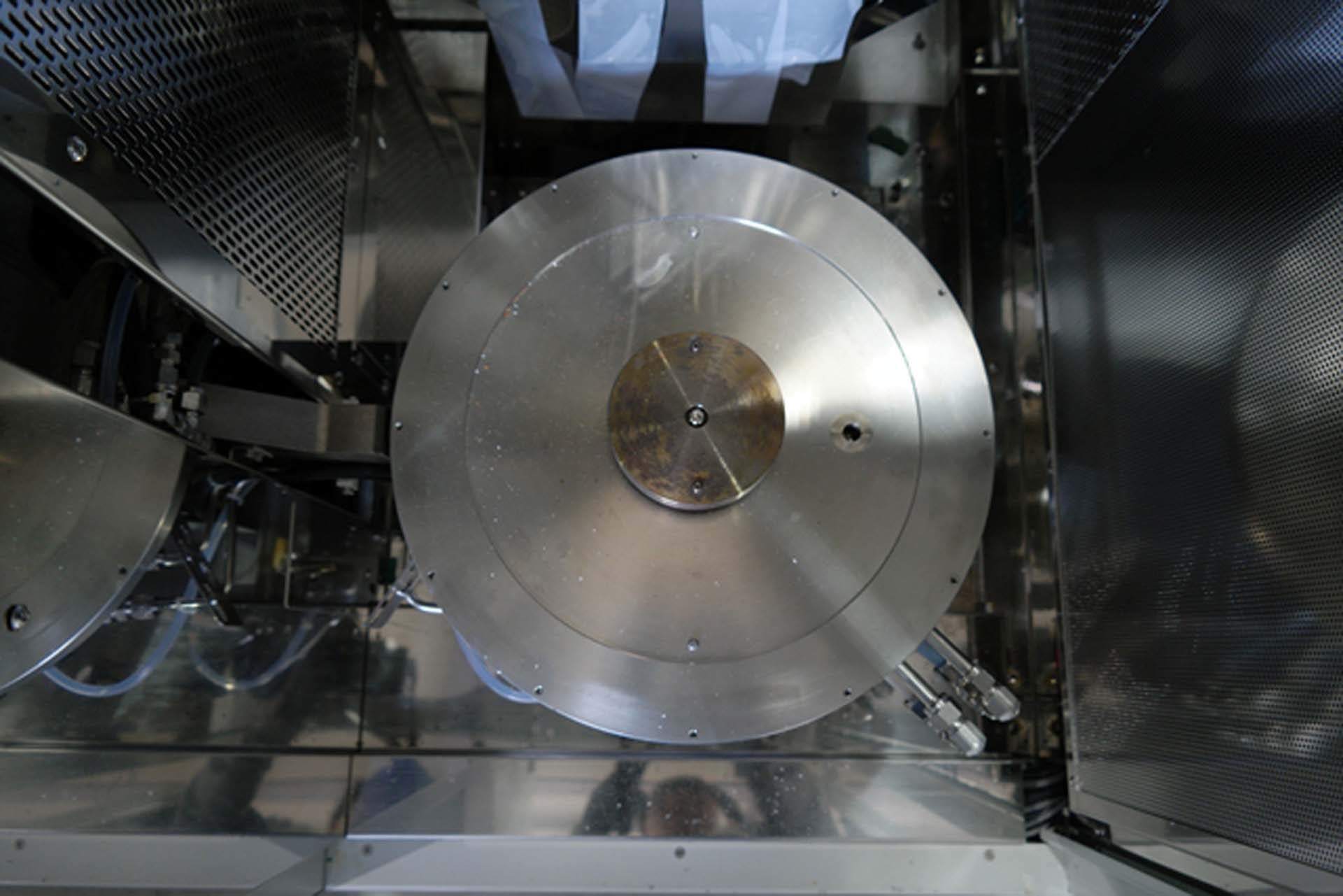

Wafer Size: 6"

Diffusion furnace, 6"

Process: PYRO (DCE)

Process gas: N2, H2, O2, DCE

Loading system:

Front operation panel

Pass box (Load lock): Cassette loader

CX 3002 Main controller

CX 1220 Mecha controller

Wafer counter, 6"

I/O Stage check: Air off

Cassette loader check: CX 3002

Furnace system:

CQ 1500 (DN-150) Temperature controller

D4EX 05414 Heater

SIC Profile

(4) Controllers

(4) Monitors

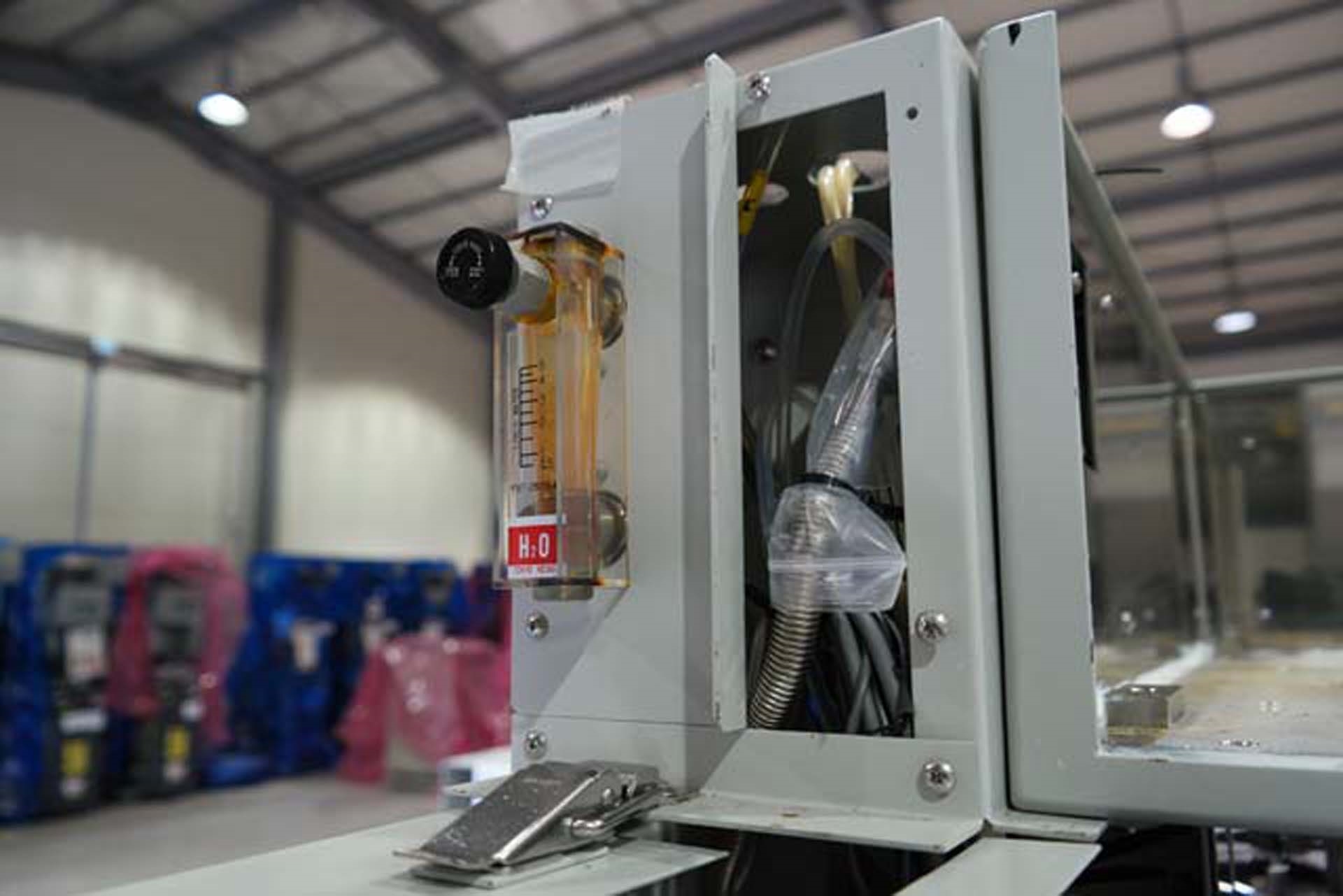

Gas system:

CX 1311 MFC Controller

MFC (STEC):

Missing MFC1

MFC2: H2 20SLM

MFC3: O2 20SLM

Model / Gas

MFC4 / O2 2SLM

MFC5 / N2 1SLM

MFM: N2 10SLM

(2) Filters

Pressure control system:

AERA RC-100F Pressure controller

Valve open / close check: APC Valve area RV-100

Burning system:

CX 1310 Burn controller

Power:

Heater: 3Φ, AC 200 V, 42 kVA

Control: 1Φ, AC 100 V, 30 A

Clean unit: 1Φ, AC 100 V, 40 A

ETC: DCE Power 1Φ, AC 100 V, 5 A.

HITACHI / KOKUSAI DD-833V is a diffusion furnace and accessory designed to provide accurate and reliable diffusion of metals and alloys of various sizes, shapes and grades. Its versatile design allows it to be used for various types of processes such as fusing, alloy deposit, vacuum alloying, and various other diffusion processes. HITACHI DD-833V diffusion furnace includes a double-wall furnace body with a central vacuum chamber for heating that is surrounded by an outer protective shell which serves to prevent heat loss. The furnace is designed to provide temperatures up to 1350°C and to be able to maintain a controlled atmosphere during the diffusion process. The furnace is equipped with a precision automatic control system which enables the user to accurately adjust the temperature with a digital display for easy control. KOKUSAI DD 833V is also equipped with a variety of accessories which allow it to be used for a variety of applications. It includes a variety of crucibles and trays, including a large tray that allows for a wide variety of shapes and sizes of materials to be processed. The furnace also includes a high-precision powder-feeder that enables it to accurately deposit powder onto the substrate and achieve precise diffusion. HITACHI DD 833V is highly reliable and durable due to its heavy-duty design which allows the furnace to operate continuously for hours without requiring any maintenance. It is also designed to be safe and secure, with an additional double-wall casing that prevents any potential accidents or malfunctions. The furnace is also equipped with a variety of sensors and monitors that enable the user to continuously monitor the temperature and atmosphere within the furnace. DD 833V diffusion furnace is designed for accuracy and reliability, providing accurate and precise diffusion of various metals and alloys. It is easy to use, safe, and highly durable, making it ideal for a variety of applications in the diffusion industry.

There are no reviews yet