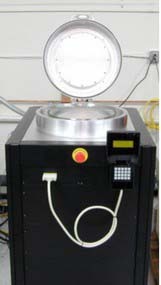

Used DSS Gemini 820 #9156790 for sale

URL successfully copied!

Tap to zoom

ID: 9156790

Wafer Size: 1-8"

Vintage: 2007

Manual Load RIE system , 1-8"

Non-load lock

18" Aluminium chamber

(1) UV filter view port

12" electrode with dark space shield

Water cooled chamber

(6) zone temperature controller

486 PC controlled with LCD Touch Screen or handheld controller

Upper RF electrode controlled manually or automatic

500 Watt RF power supply

(4) MFCs

Mechanical pump & Chiller

208V, 3 phase, 60 Hz

2007 vintage.

DSS Gemini 820 is an etcher / asher designed for dry etching applications in the semiconductor industry. It offers a wide range of etching capabilities, making it an ideal choice for process development and production applications. Gemini 820 features a variety of process chambers, including: three end point reaction chambers, three incident lighting chambers, two cleave chambers, two microwave end point sensors, and two gas dead volumes. It also features an ultrasonic blend chamber for uniform etching and a BioSpray chamber for resistive coatings. DSS Gemini 820 provides enhanced process accuracy and uniformity through its software mechanisms. It is designed to quickly and accurately achieve the desired pattern. The software mechanisms also enable end point detection of etches with an accuracy of ±7% and a precision of 1.5 nanoseconds. Additionally, DSS Gemini 830 has low oxygen level monitor for real-time monitoring of the ambient conditions in the process chamber. This feature ensures that the etch quality is maintained and eliminates the need for manual ambient monitoring. DSS Gemini 830 provides maximum process control and control of process fluids such as Argon, XeF2, CHF3, and CF4. It also features two independent piezo valves for careful control of the chamber pressures. The process can be started manually or with preset recipe parameters. Separate plasma chamber controllers allow for independent control of each chamber. DSS Gemini 830 incorporates a variety of safety features, including automatic chamber shutdown if an emergency situation is detected. It also features a modular design for easy installation and maintenance. Its advanced PC software provides easy-to-use machine control, configuration, monitoring, and data logging. Overall, DSS Gemini 830 provides numerous advantages for the etching process, from improved accuracy and uniformity to improved process control and safety features. It is an ideal choice for process development and production applications, and provides a comprehensive set of capabilities for dry etching.

There are no reviews yet