Used DSS Gemini 830 #9156789 for sale

URL successfully copied!

Tap to zoom

ID: 9156789

Wafer Size: 1"-8"

Vintage: 2007

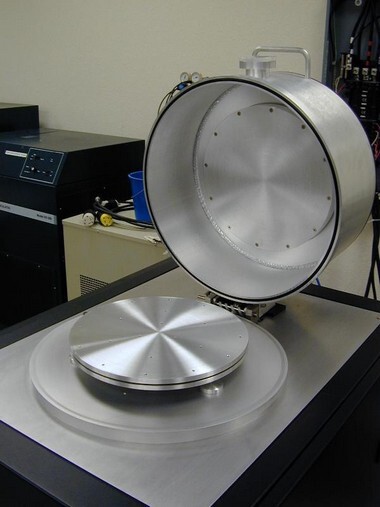

Manual Load PECVD system, 1-8"

Non-load lock

18" Aluminium chamber

(1) UV filter viewport

12" electrode with resistance heat to 400 degrees C

(6) zone temperature controller

486 PC controlled with LCD Touch Screen or handheld controller

Upper RF electrode controlled manually or automatic

500 Watt RF power supply

(4) MFCs

Mechanical pump & Chiller

208V, 3 phase, 60 Hz

2007 vintage.

DSS Gemini 830 etcher / asher is a highly precise and productive equipment designed to meet the high precision etching and ashing needs of electronics manufacturing, automotive, and medical applications. The 830 features a small footprint and is easy to integrate into production lines. It delivers ultra-precise etching and ash patterns that improve performance and reduce waste. The 830 comes equipped with a high performance cutting edge laser and dust free cutting system which allows for high precision etching and ashing on different materials. The industrial grade optical lens and advanced unit control allow for precise and consistent results. Its 1 micron repeatable accuracy allows you to produce micron level features with ease. The 830 provides high speed etching and ashing at 5m/s on multilayer dielectric materials, such as glass, ceramic, and plastic. Its high-power laser provides consistent and reliable cutting results. The machine is equipped with independent lifting platforms for easy loading/unloading. The lift is encapsulated which makes the machine safe to operate and resistant to wear and tear. The 830 is designed with a large display that allows uninterrupted production with no interruption of light. The ergonomic design ensures operator comfort and easy access to parts and the control panel. It is equipped with control systems that can be operated from the front or the back of the machine. The 830's advanced safety measures include permanent fume extraction filters, safety lamp, and cleaning tool for prevention of splash-back. The asset is also equipped with an auto shut-off feature for emergency situations. The 830's high speed etching and ashing capabilities are made even more efficient with its advanced PC control model which allows for remote monitoring of operations, complete with alarm systems. Its advanced production automation systems, such as barcode recognition, job queue, and job merging, also offer improved productivity. The 830 etcher / asher is designed to meet the demands of high precision, high speed electronics and automotive parts production. Its small footprint, high precision cutting technology, advanced equipment controls, safety features, and advanced automation capabilities provide the ultimate in etching and ashing productivity and quality.

There are no reviews yet