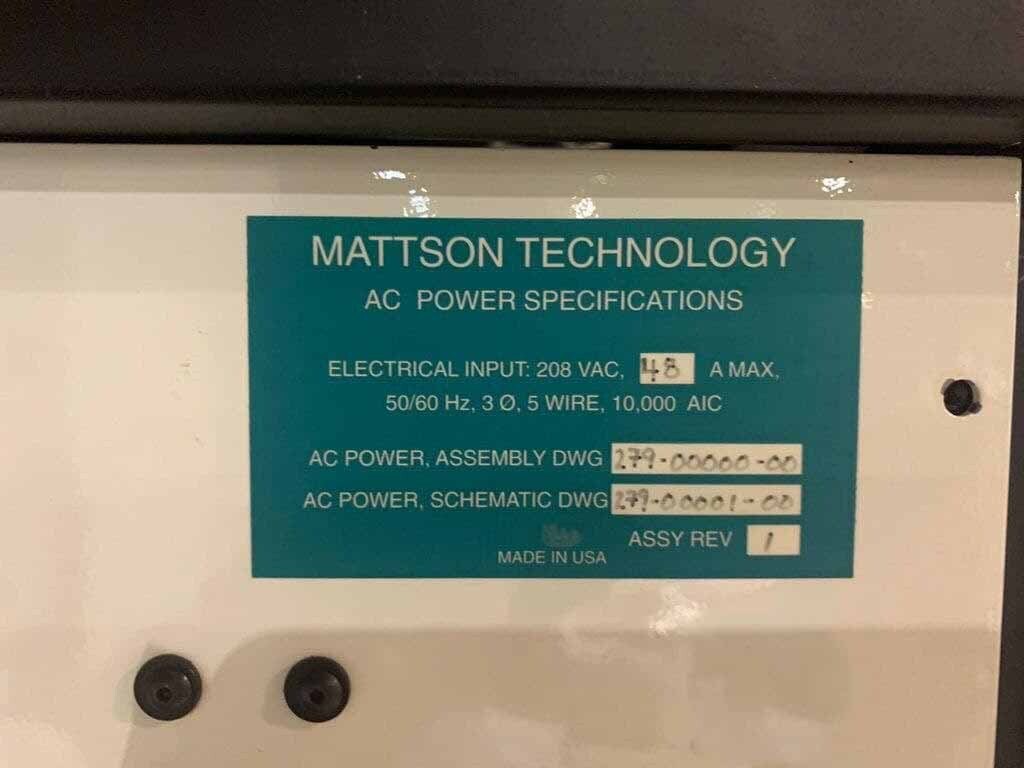

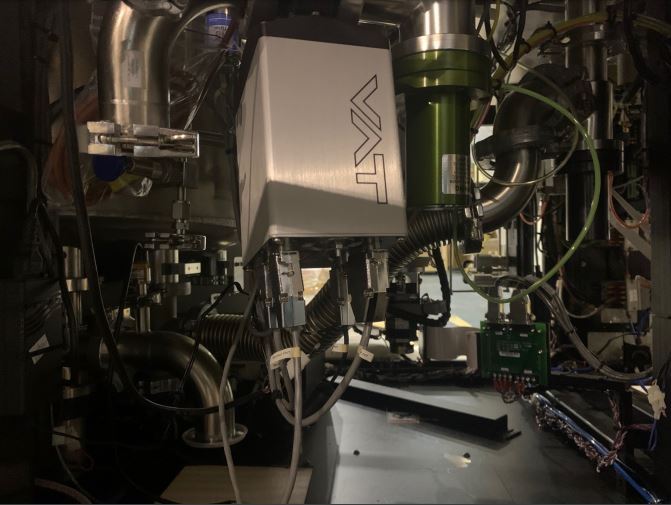

Used MATTSON Aspen II #9398659 for sale

URL successfully copied!

Tap to zoom

ID: 9398659

Wafer Size: 8"

ICP System, 8"

MATTSON Endpoint detection system

With fixed filters: 430 and 520

Cable length: 19 ft

(3) RF Cables and signal cables

(2) Heaters

MFC

Chambers:

Back chamber:

366 MHz CPU: Analog in and PCB out

Floppy Disk Drive (FDD): DI/DO Cards

Chassis: Power supply

Gas channel: Bottom feed channel

Cool down station: No water cooling

Gas lines

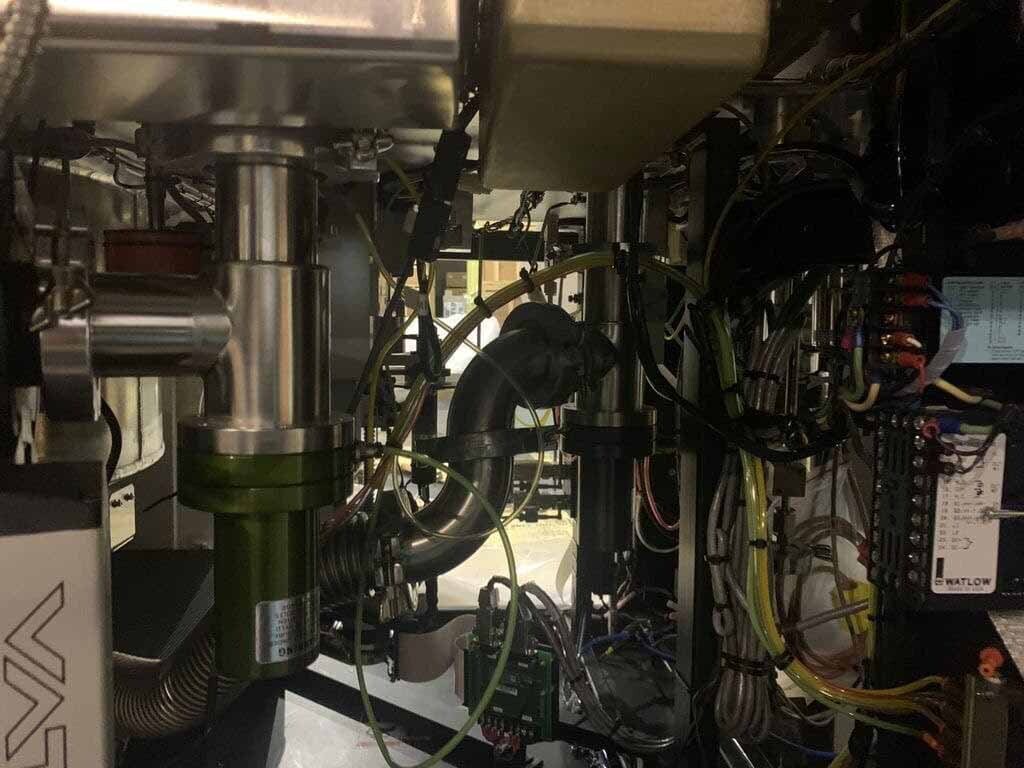

Right chamber:

366 MHz CPU: SEC II Card

Floppy Disk Drive (FDD): Robot stepper (SMC-PC3)

Chassis: Backing plain

Gas channel: Junction box

Cool down station: Lexan plates

Gas lines with filters

Front end:

26" Opening with separate operator interface

4-Color light tower

Operator / Engineering monitor: TFT Design monitor

Gas box with sub frames

EMO Buttons

Interlock circuit: Push button switches

Hanging panels

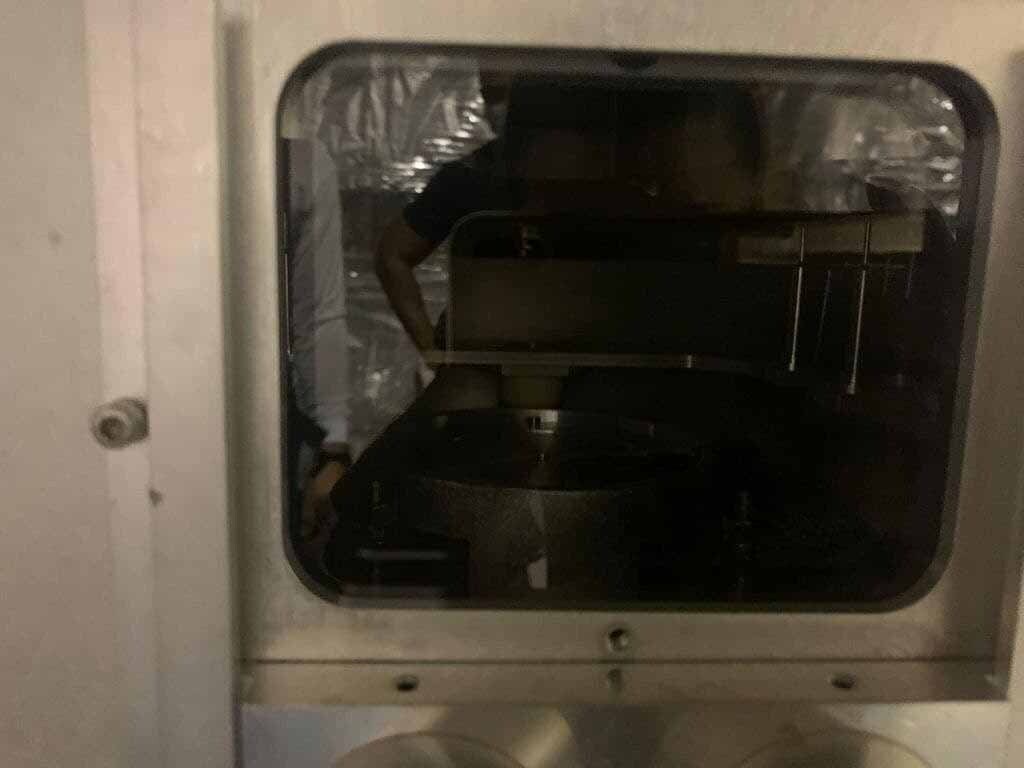

Load lock:

Single load lock

(2) Cassette stations

Capability of queuing lots

Pin search assembly: Proximity sensors

Load lock seal: Lip seal

Platform and cassette:

(4) 25-Slot cassettes

Rotating cassette nests, 8"

Cool down station: Flat cool down station without water lines

Load lock fast exchange

Transfer robot:

Main robot: 3-Axis robot with flex cable

Robot arm: (4) Adjustable paddles with standard arm

Slit door

Wafer sensors: Paddles, front and rear cassettes

Shuttle: 26"

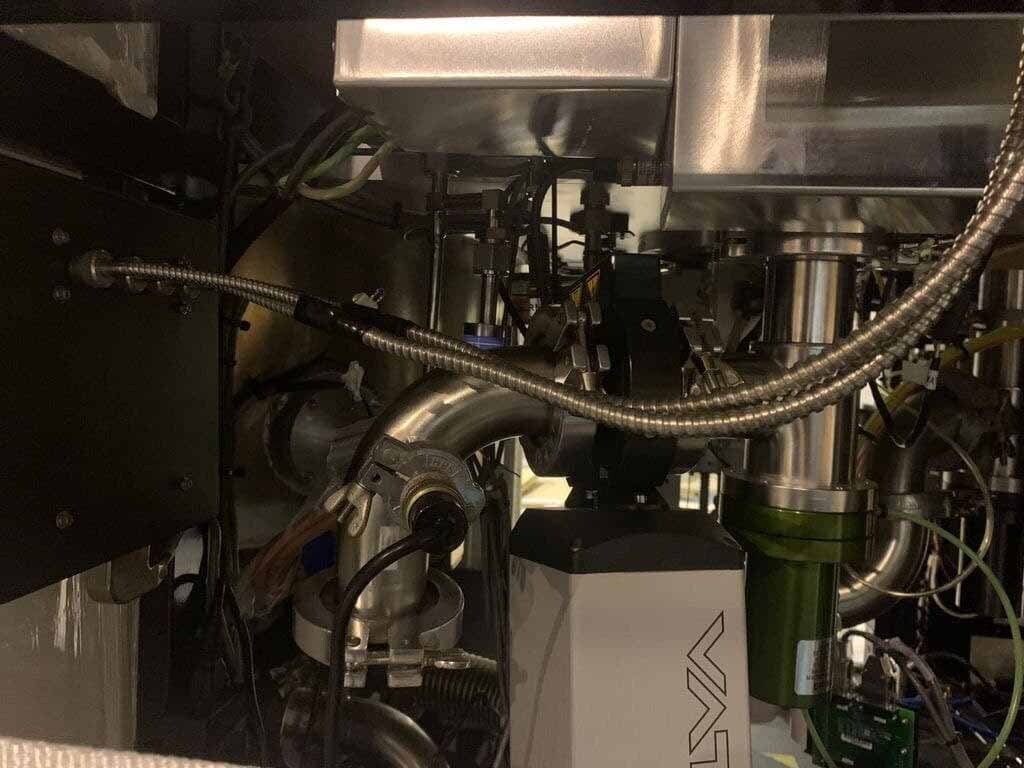

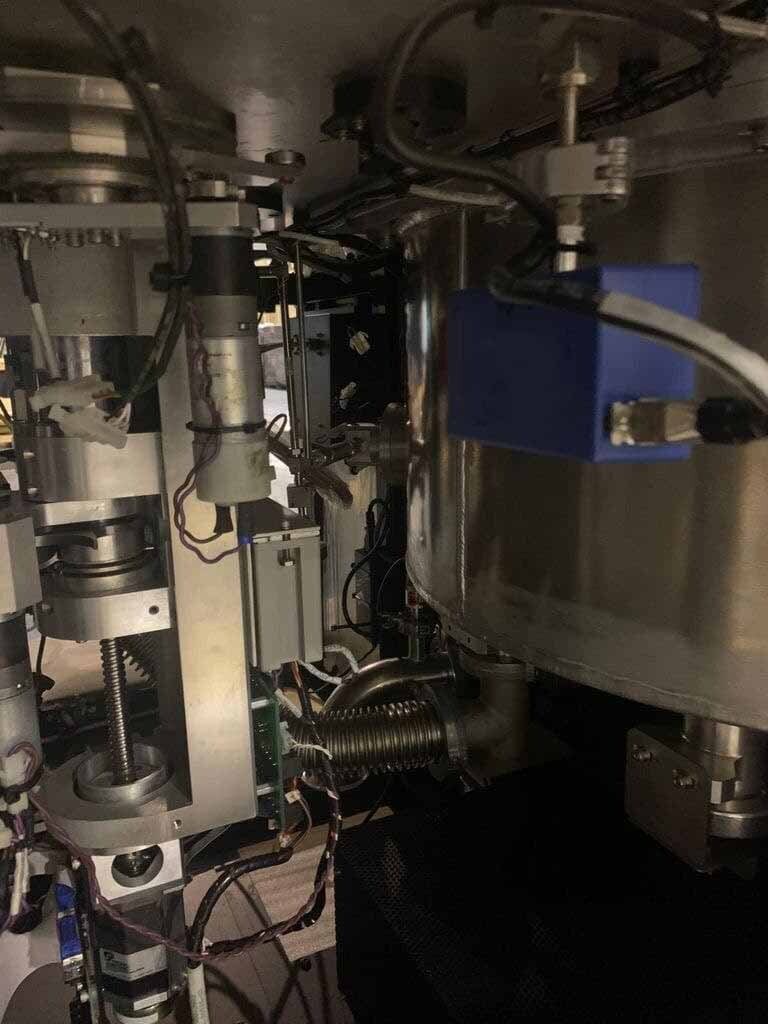

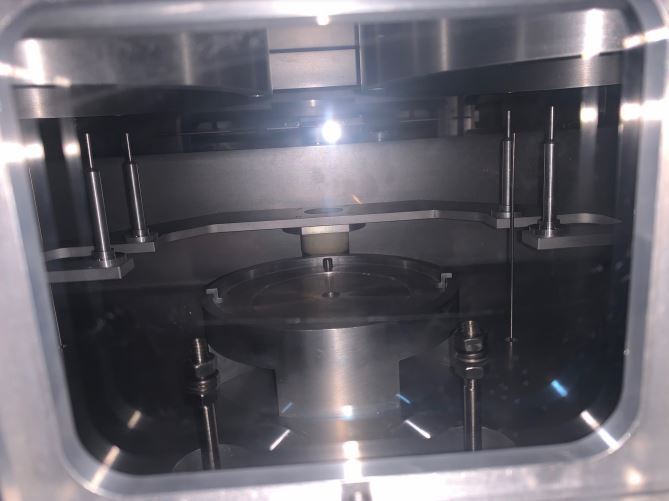

Process module:

Chamber right and back:

Tube type: Quartz tube

Standard process window

ICP Chamber O-ring type: Flurosilicon

Temperature controller: WATLOW 988 / EZ Zone

Thermal couples: Spring loaded TC

Lift pin assembly

Grids / Guide rings: Extended guide ring

Electrical feed through

Manifold and ceramic parts

Isolation valve

Top plate

Load lock

Chamber

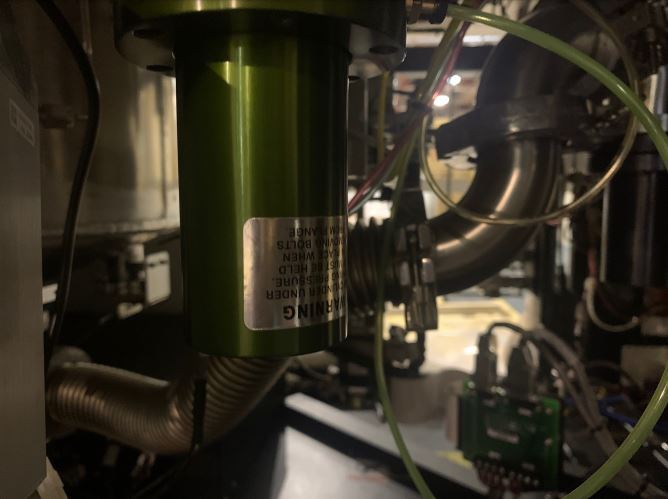

Pressure controller:

VAT Valve pressure controller

Chamber manometer: 10 Torr

Load lock manometer: 100 Torr

Shuttle manometer: 1000 Torr

RF / MW System:

RF System: Top RF 13.56 MHz

(3) RFPP10 RF Generators: (2) Power cables missing

TRAZER AMU 10D-2 RF Top match, P/N: 914-92003-00: (2) Vacuum capacitors missing

Re-silvered RF coils

(125) RF Vacuum caps: 100PF

AC Box: 2-3 Phase generators with safety cover

DC Box

Gas system:

Gas VCR gasket: Stainless steel and Nickel

Gas line / Gas / Range

Gas 1 / O2 / 1000 SCCM

Gas 2 / N2 / 1000 SCCM

Gas 3 / N2/H2 (4%) / 2000 SCCM

Gas 4 / CF4 / 100 SCCM

Side:

Gas 1 / O2 / 5 SLM

Gas 2 / N2 / 1 SLM

Gas 3 / CF4 / 200 SCCM

Gas 4 / O2 / 1 SLM

Rear:

Gas 1 / O2 / 10 SLM

Gas 2 / N2 / 1 SLM

Gas 3 / CF4 / 200 SCCM

Gas 4 / O2 / 1 SLM.

MATTSON Aspen II is an advanced etching equipment that provides precision etching with high throughput and low cost of ownership. It is designed to increase productivity while providing a high level of flexibility and control over etching parameters. Aspen II is used in numerous types of applications and research projects requiring etching of various materials. It is suitable for etching many substrates including silicon, quartz, molybdenum, and stainless steel. The system features an adjustable stage to easily etch large or small substrates including corners, edges, and steps. The large etching chamber allows for etching multiple wafers at one time in order to speed up production. MATTSON Aspen II is well equipped with an ultra-precision robotic X, Y, Z drive with a maximum speed of 11 mm/sec. It also features high speed vision-based alignment and auto-focusing. The unit also has a chiller to optimally cool the substrate in order to stabilize the etching process. The etch rate is very stable, providing flexible etching conditions with the ability to repeat high performance results. The machine is equipped with a vacuum pump and is capable of creating a low-vacuum environment with a chamber pressure of 5 mTorr. The tool also has a built-in pre-chamber degassing asset which allows for pristine etching conditions. Aspen II is also capable of anisotropic etching where the etch rate along the vertical axis is higher than etch rate along the horizontal axis. MATTSON Aspen II features a wide range of etching chemistries including oxygen, chlorine, sulfur hexafluoride, and fluorine radicals. In order to ensure reproducible results, the model also features remote control over key parameters such as electrical power, temperature, and ion source. Additionally, the equipment can easily be integrated into existing semiconductor processes. Aspen II is an excellent choice for high-performance, high-throughput etching. Its robust construction and precision capabilities make it a perfect choice for many different etching applications.

There are no reviews yet