Used MATTSON Aspen III #9245068 for sale

URL successfully copied!

Tap to zoom

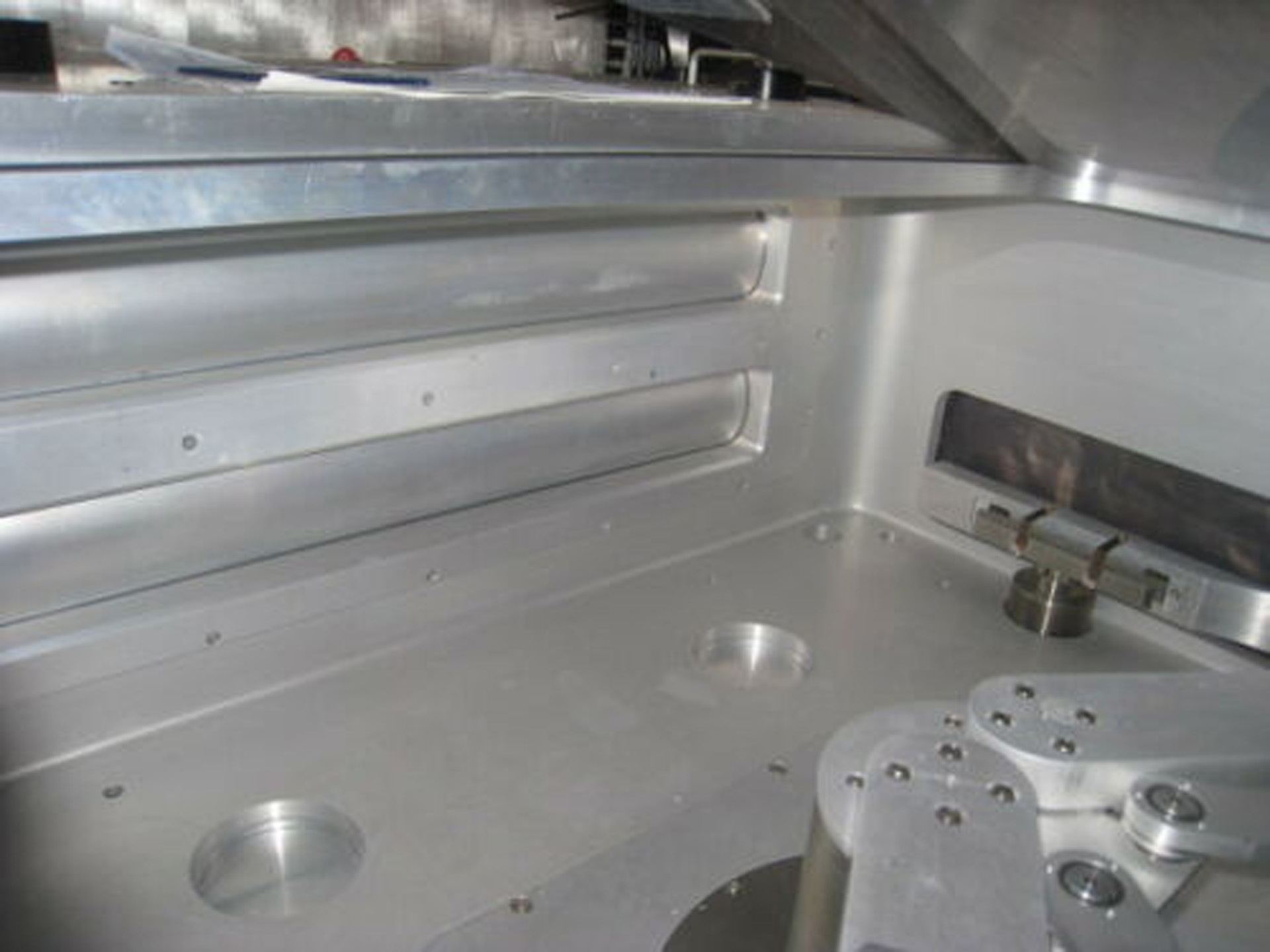

MATTSON Aspen III is a powerful etcher and asher, built for high-end applications requiring precision and speed. The equipment features a four-station system with a large chamber and barreled-gas heating process. The chamber is large enough for deep etching of up to 2" thick product surfaces. The work table is supported by precision roller bearings, providing superior etching accuracy and consistent material uniformity. The machine is designed for flexibility, allowing for multiple and selective processing on various material types. Having a selectable four-tier stacking unit allows for decrease in production time with improved throughput. Aspen III also features a powerful barreled-gas heating process, allowing for minimization of heat transfer and more accurate temperature control throughout the etching process. This process is used to penetrate the hard metal more deeply and more quickly than other etching methods. Heat is transferred between coils located in the center of the chamber, eliminating the risk of etching damage caused by surface contact with hot tools. The patented process is designed to provide up to 20% better results over other etching methods, providing uniform etch depth and a high quality finish. The machine is also automated, coming with advanced microprocessor-controlled software. This software is capable of both manual and automated operations, and it allows for easy customization of jobs and parameters. The software also has an onboard troubleshooting feature integrated into it, allowing technicians to quickly diagnose problems and make adjustments to ensure optimal production. Overall, MATTSON Aspen III is an advanced etcher and asher, designed to provide precise and powerful etching for high-end industrial applications. The advanced heating process, precise table support, and automated software make the tool an effective solution for both automated and manual operations requiring both accuracy and speed. With its large chamber and stacking asset, the model can meet production demands of any facility.

There are no reviews yet