Used STS / CPX Multiplex ICP #9313228 for sale

URL successfully copied!

Tap to zoom

ID: 9313228

Wafer Size: 6"

Vintage: 2005

Si Etcher, 6"

Pressure controller: VAT PM-7 65046-PA52-AJAI/0016

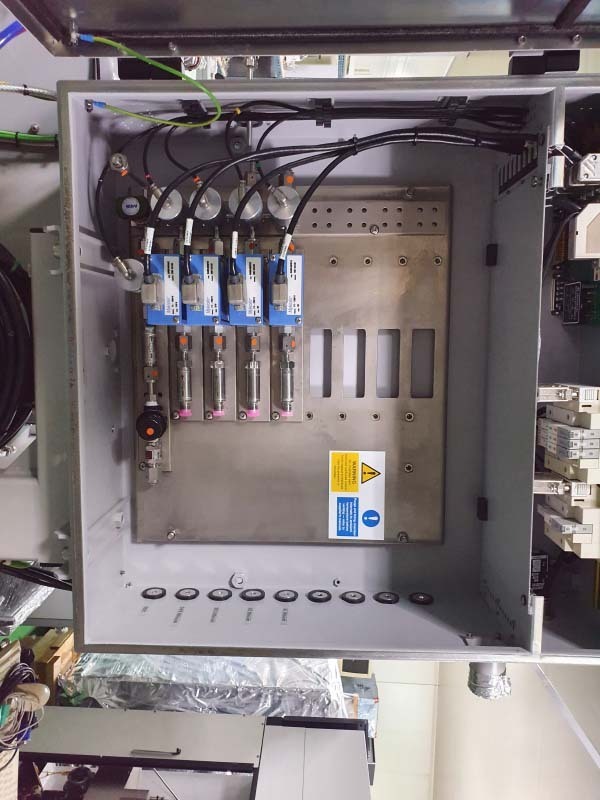

Gas module:

Chamber:

Ar 100SCCM

O2 100SCCM

SF6 300SCCM

C4F8 200SCCM

RF Generator:

ENI ACG-3B 13.56

ENI ACG-10B-07

ADVANCED ENERGY LF-5 AE 50~460MHz

Chiller: AFFINITY RWA-012L-CE35CBD4 STS

Turbo pump: LEYBOLD MAG 1500CT

Dry pump: EDWARDS iQDP80

Pump: VARIAN SH100

2005 vintage.

STS / CPX Multiplex ICP etchers are a type of etcher or asher that use inductively coupled plasma (ICP) technology to etch or ash a variety of photoresists and other products. This etcher is a highly efficient tool that allows for precise control over the process parameters such as the power, frequency, gas flow and pressure. STS Multiplex ICP etcher is designed with a flexible chamber that can be re-configured with different ICP sources, depending on the application and the material being processed. The ICP sources can be switched quickly, allowing for a fast changeover from one job to the next. The equipment also includes a gas delivery system and a cooling group that allows for the introduction of a variety of gases into the chamber. The gases can be used to produce a specific etch or ash pattern and can be adjusted to control the etch rate and selectivity. CPX Multiplex ICP etcher is designed with a number of features that make it ideal for a wide range of applications. The precision power control allows for improved etch or ash uniformity and enables the user to achieve highly precise substrate etching or ashing. In addition, the unit is equipped with an auto-focus feature that allows for the auto-focusing of the plasma in order to produce a uniform etch or ash. This is especially useful when processing oblique wafers. The machine also has an integrated cooling tool that helps to prevent overheating. In summary, Multiplex ICP etcher is a highly efficient etching or ashing tool that is suitable for a range of applications. It has a flexible chamber that can be easily reconfigured to suit the specific requirements of the job at hand, and the auto-focus feature and adjustable gas delivery asset provide excellent control over the etch rate and selectivity. In addition, the precision power and cooling systems allow for improved uniformity and prevent the model from overheating.

There are no reviews yet