Used STS / CPX Multiplex #9119434 for sale

URL successfully copied!

Tap to zoom

ID: 9119434

Wafer Size: 8"

Vintage: 2005

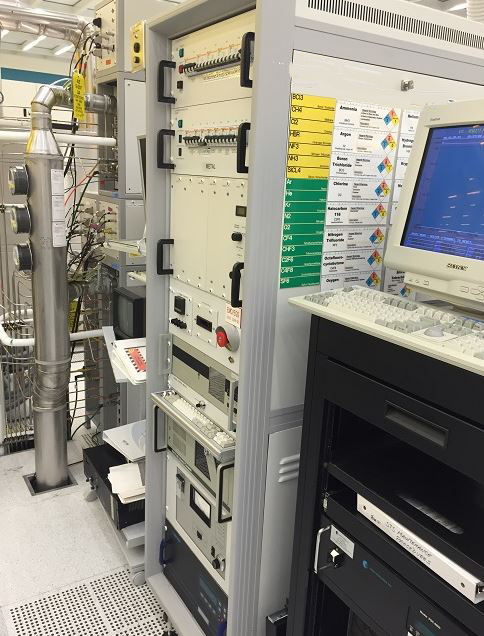

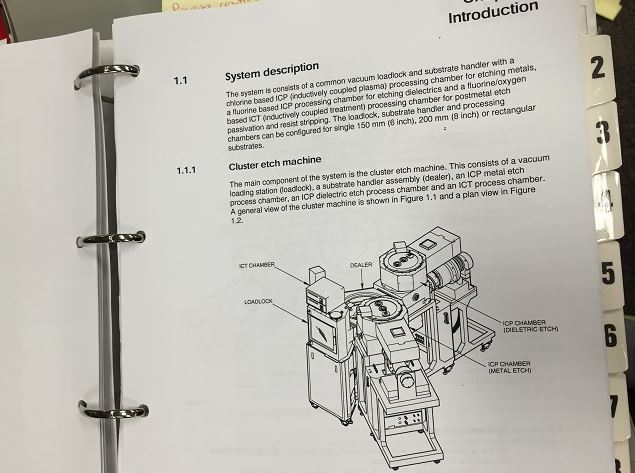

Cluster ICP etcher, 8″

(3) Chambers

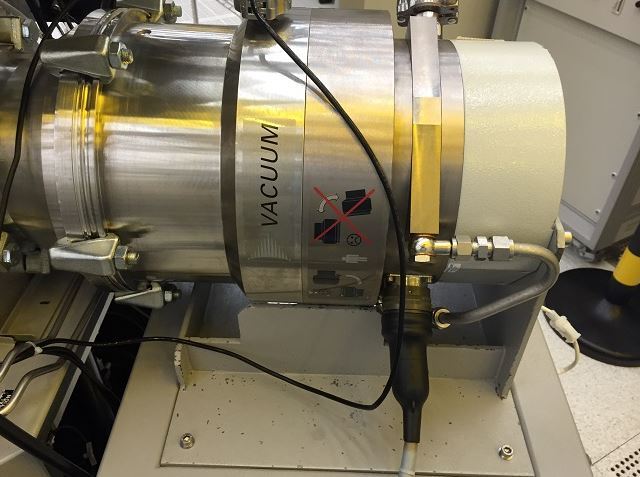

Turbo on the wafer handler

C033 Cluster handler

(2) Temperature controlled lids

Loadlock: Brooks VCE 4 with manual door

Corema chiller on Metal ICP chamber

ICP chamber (Metal etch)

12-Process gas manifold

Bias capabilities

Chuck: heat exchanger, no electric

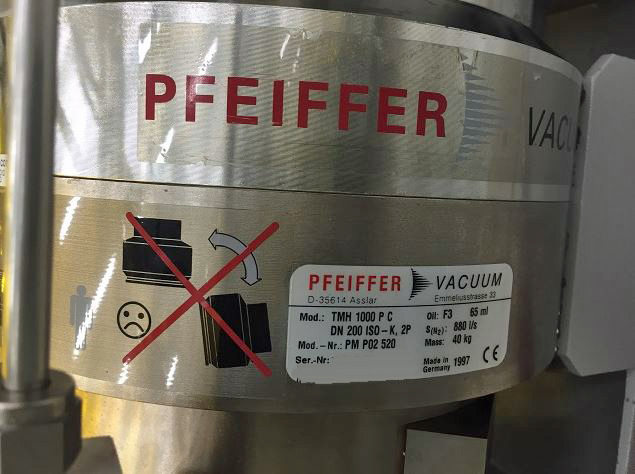

Turbo pumps: TMH100

ICP chamber(Dielectric Etch)

12-Process gas manifold

Bias capabilities

Processed: silicon etch

Chuck: heat exchanger, no electric

Turbo pump: TMH100

ICT chamber (Asher / Stripper)

(4) Gases: N2, O2, NH3, CF4

Turbo pump

Chillers: NOAH

Vacuum Pumps: not included

Software: Windows 2000

Currently warehoused

2005 vintage.

A STS / CPX Multiplex is an etcher/asher used in the process of microstructuring for many advanced industrial applications. An etcher/asher involves the using of chemical solution to remove or etch material from a substrate before undergoing the asher process. The etching process involves applying an etchant solution comprised of a reactive acid and other substances to the substrate and then etching away at its surface. This process is used to create cuts, holes, slots, or other shapes on semiconductor or metal materials. STS Multiplex is an advanced version of this technology, designed to provide the broadest range of etching and ashing capabilities in the industry. This tool is designed to precisely control both etching and ashing processes. It uses a patented computer-controlled process (CPC) to ensure accurate and repeatable results when etching or ashing various materials. The CPC system allows the user to precisely control the etch rates, allowing for the uniform etching and ashing of materials. This etcher/asher is equipped with an automated multi-zone station design which allows for the processing of multiple wafers with different etch or ashing parameters. It also has built-in temperature sensing and monitoring technology which helps ensure precise and accurate results when etching and ashing. CPX Multiplex also has high throughput capabilities, with accelerated etch rates that can be up to 35% faster than those of conventional etchers. Multiplex is designed to reliably provide precision results with high accuracy and uniformity. It also offers flexibility, scalability, and cost-efficiency, making it a valuable tool for various industries requiring microstructure processes. Its versatility and advanced features make it suitable for a wide variety of applications, such as the etching of transistors, diffusions, and contacts, as well as the ashing of metallic or semiconductor materials. All of these properties make STS / CPX Multiplex an ideal choice for advanced industrial applications.

There are no reviews yet