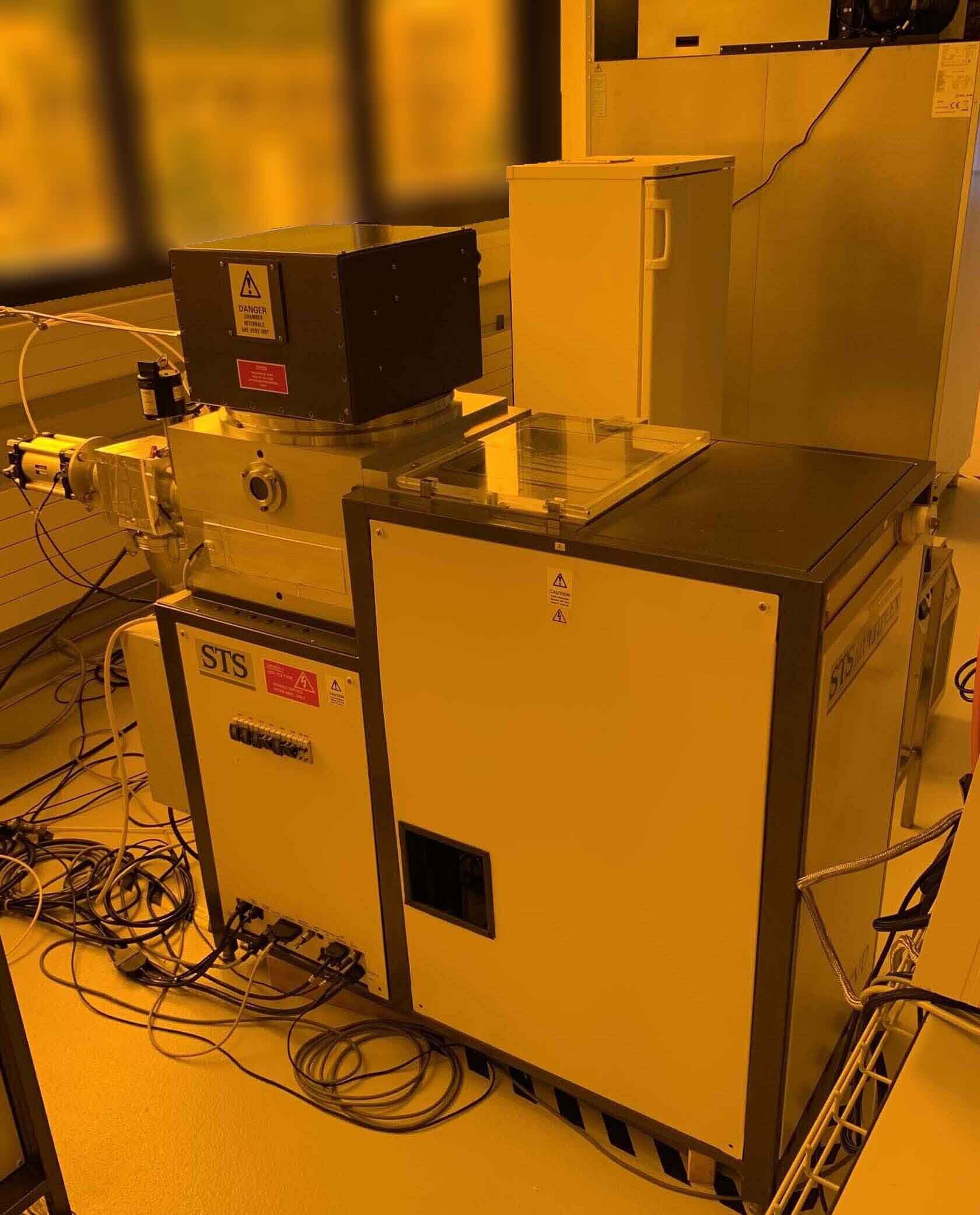

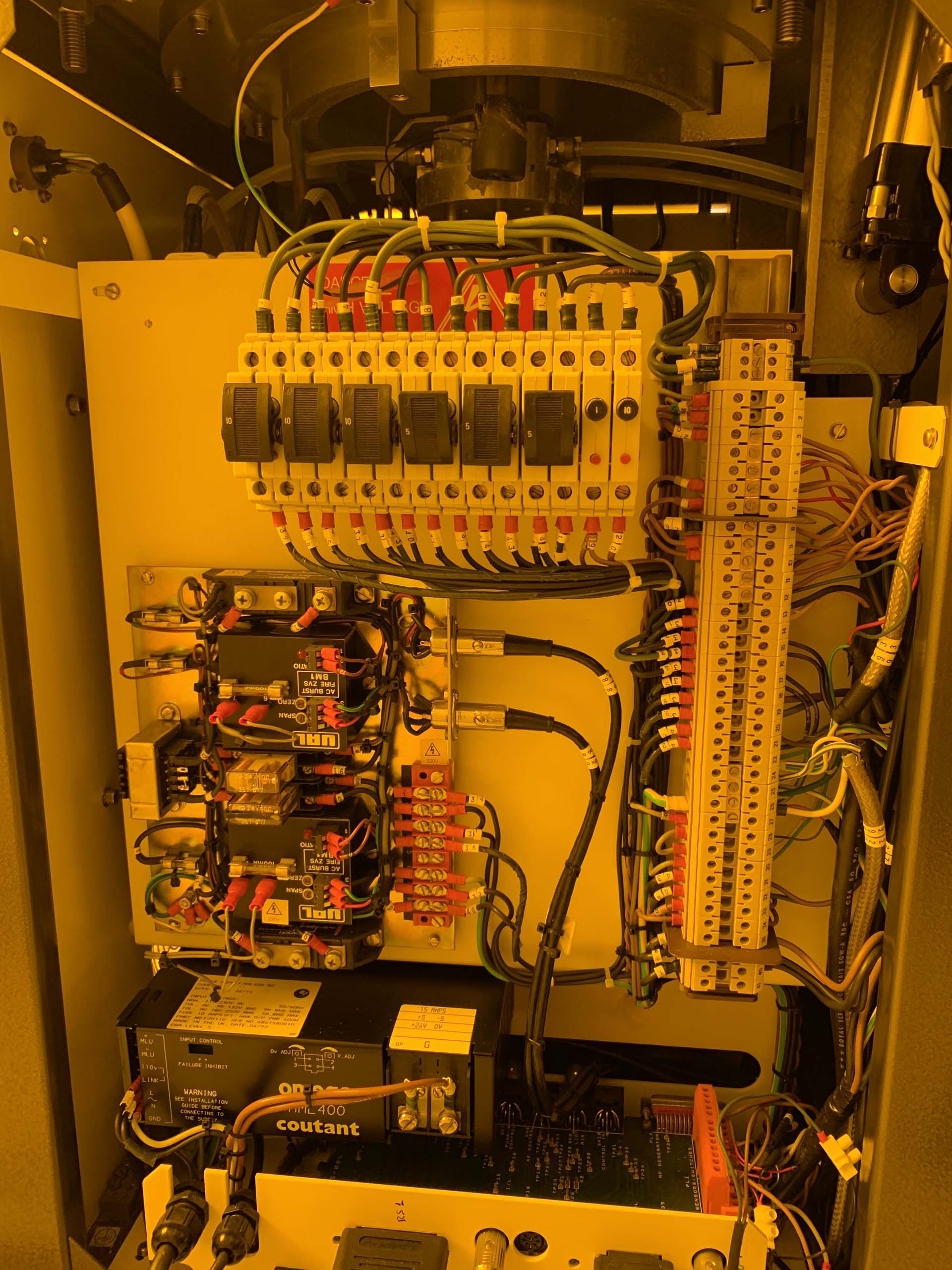

Used STS / CPX Multiplex #9206283 for sale

URL successfully copied!

Tap to zoom

ID: 9206283

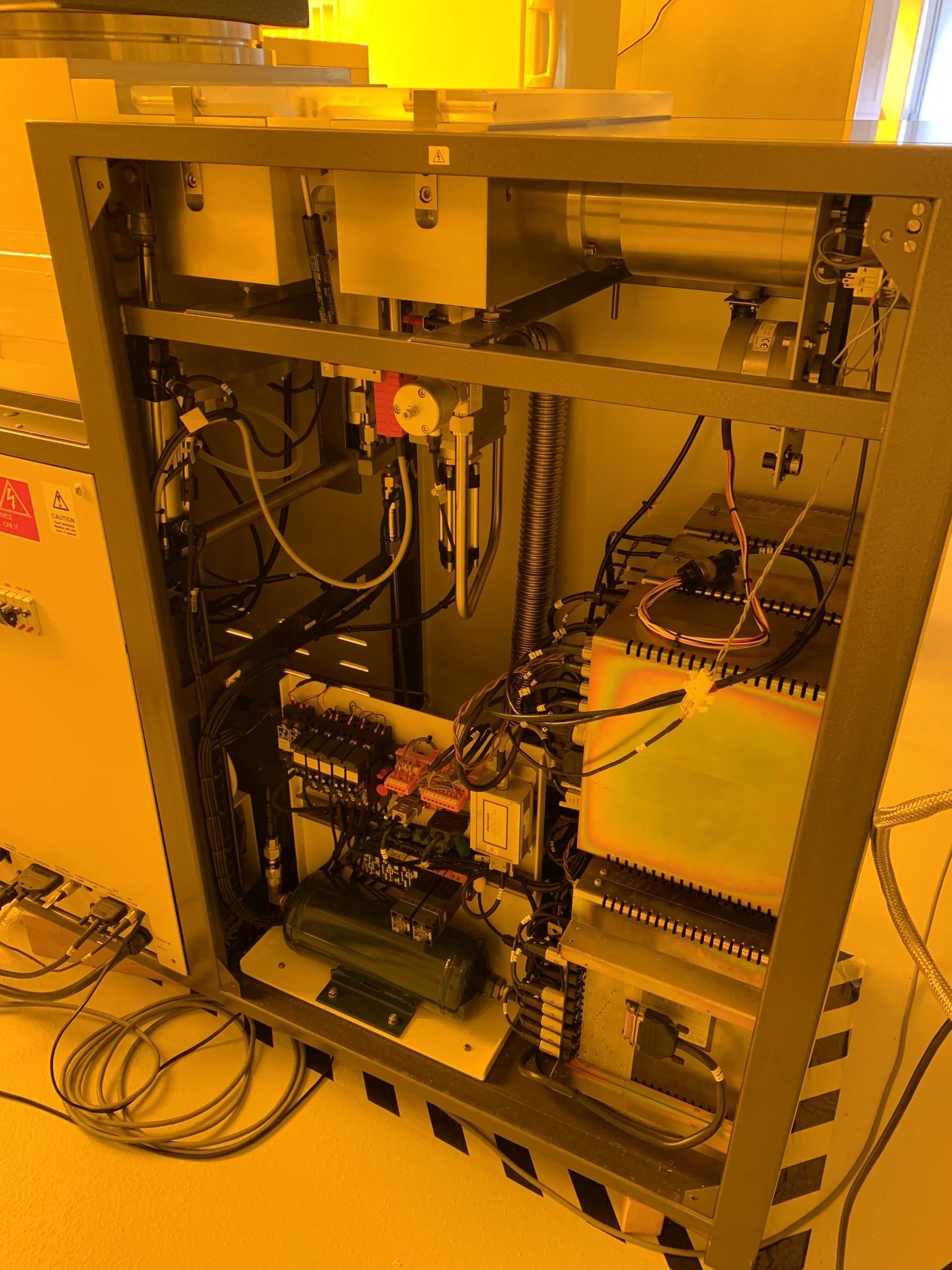

Plasma Enhanced Chemical Vapor Deposition (PECVD) system

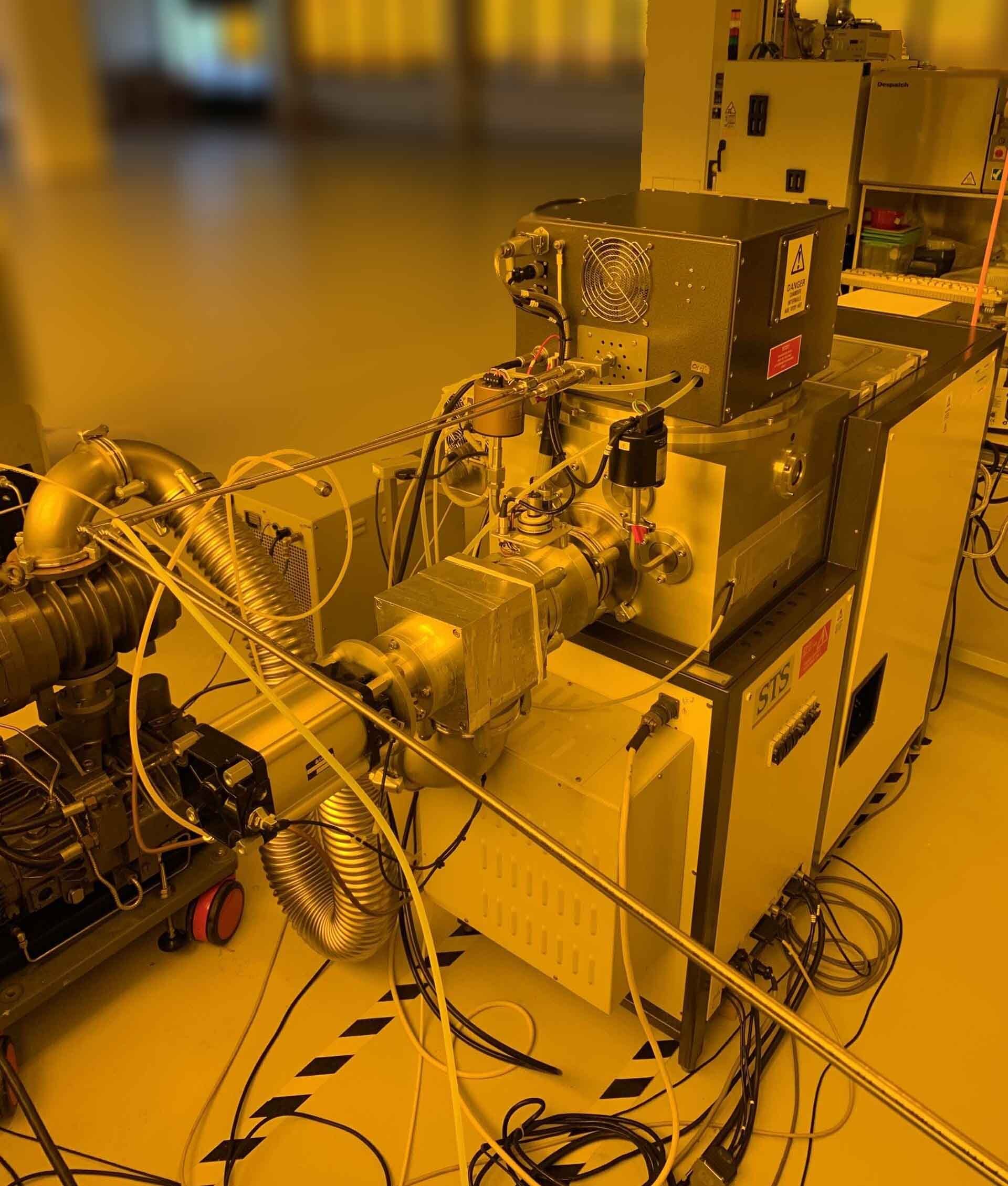

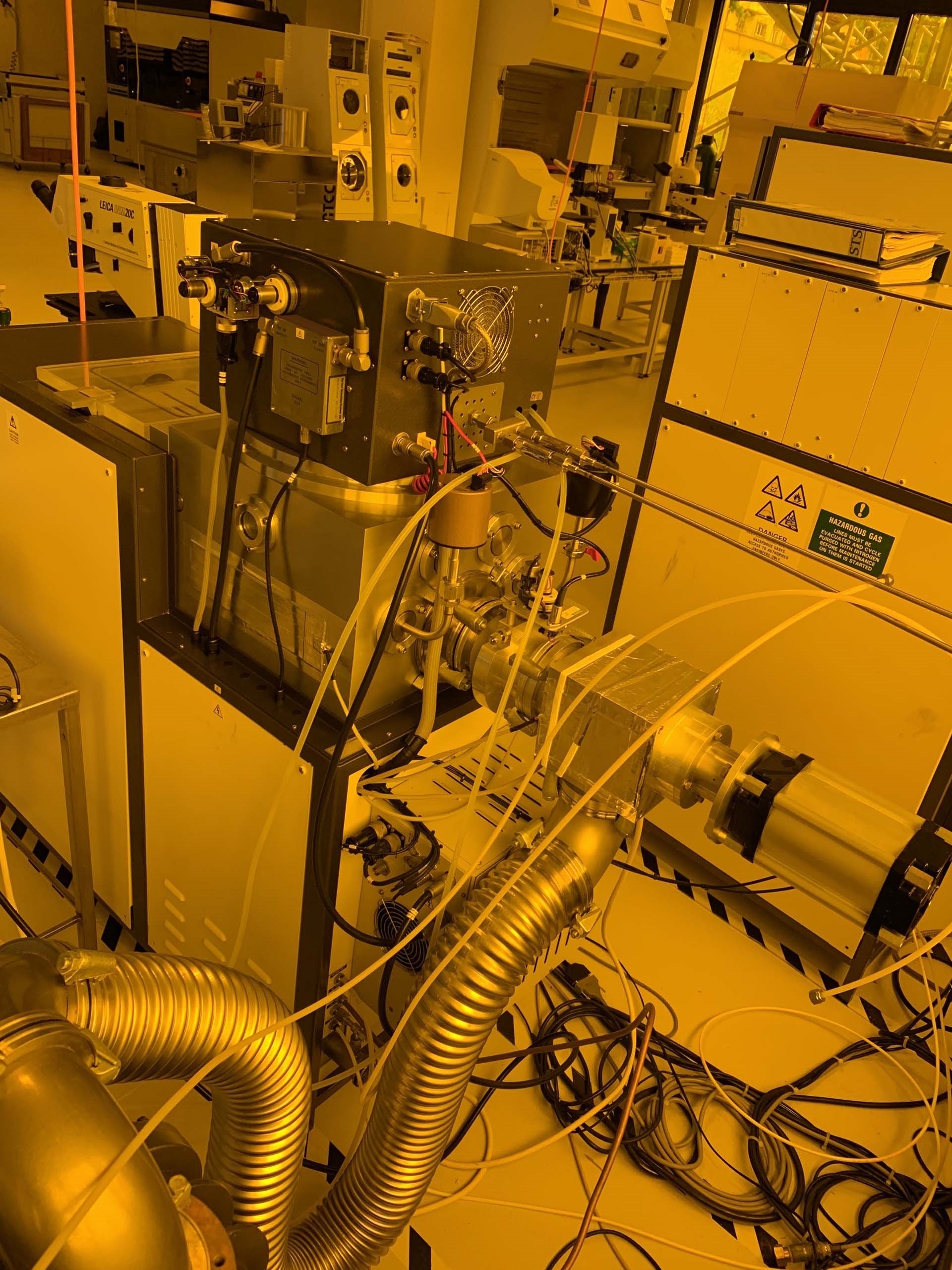

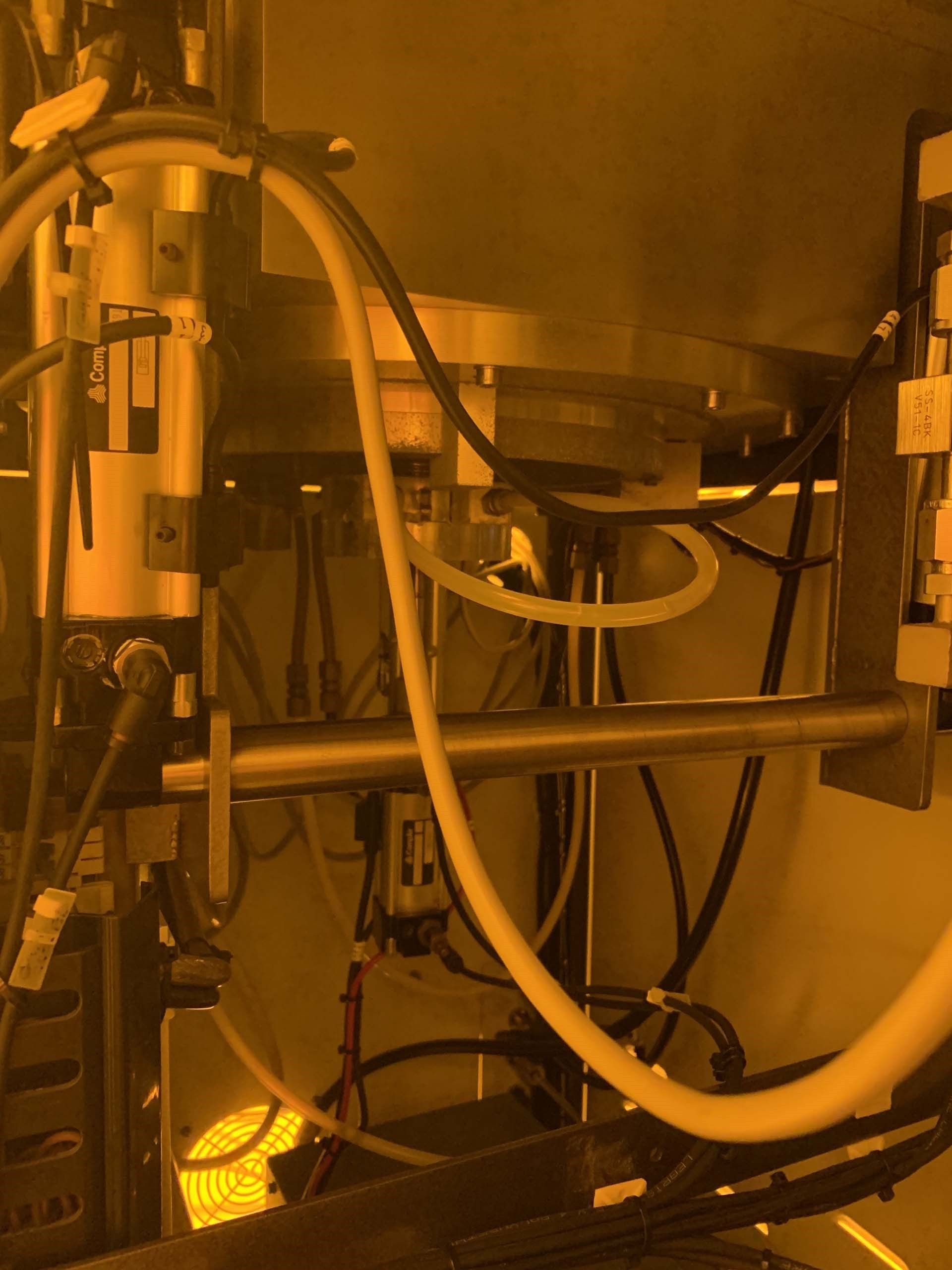

Vacuum load-lock: Manual

Load-lock / Process chamber: Automatic transfer

Loader substrates: Up to 200 mm diameter

Chuck: 100 mm diameter

Load lock: MK4 Single wafer load lock

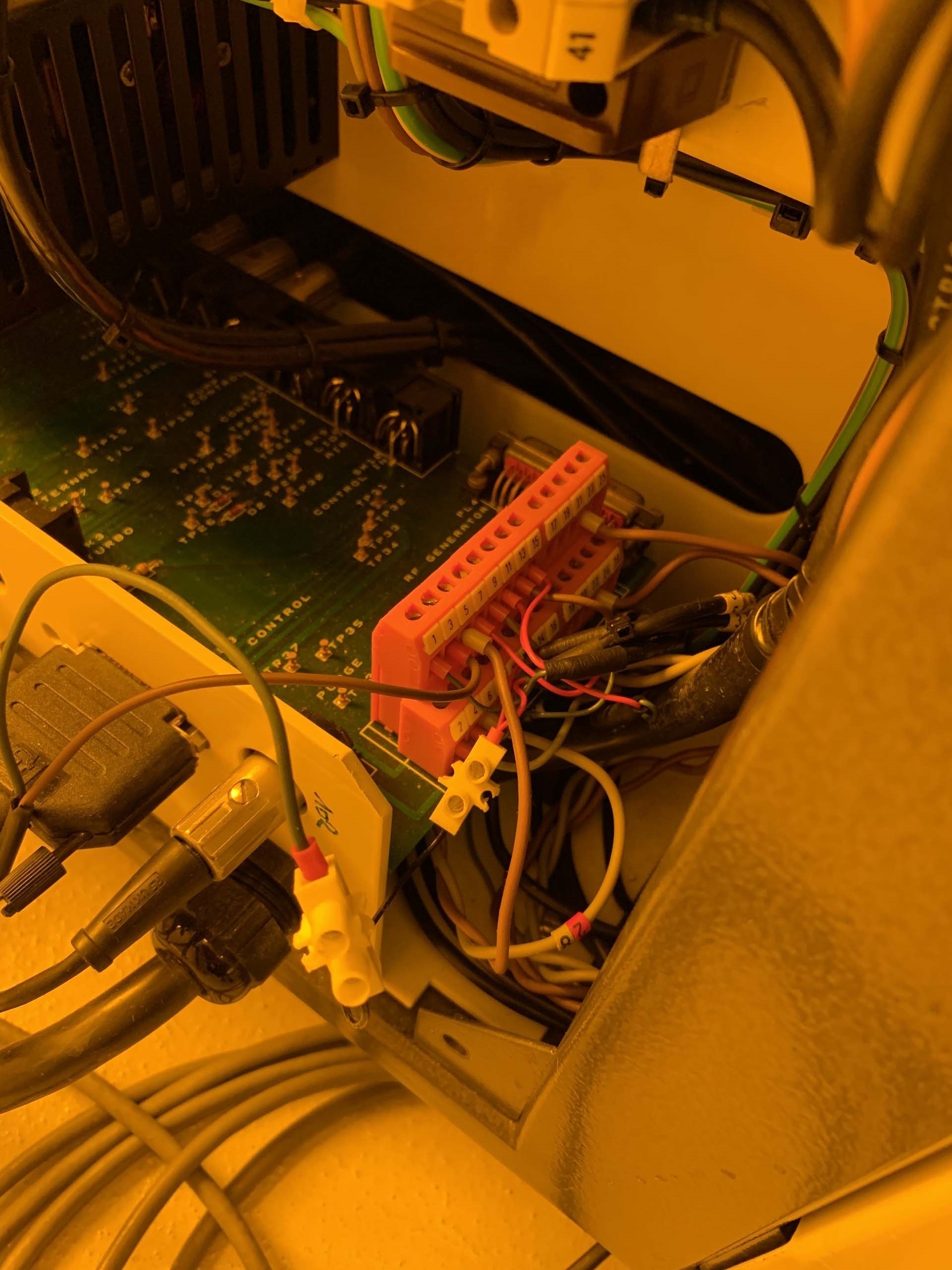

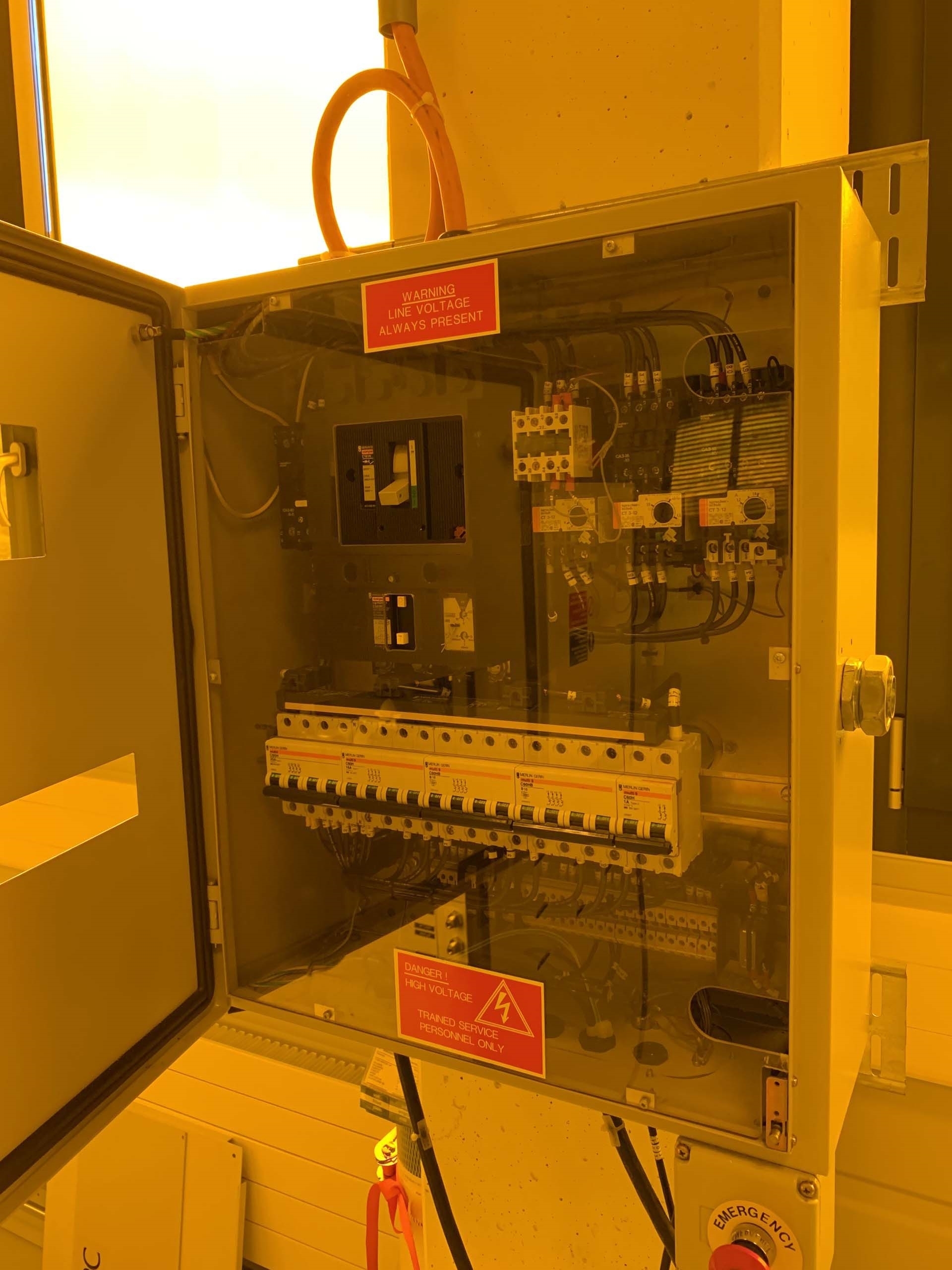

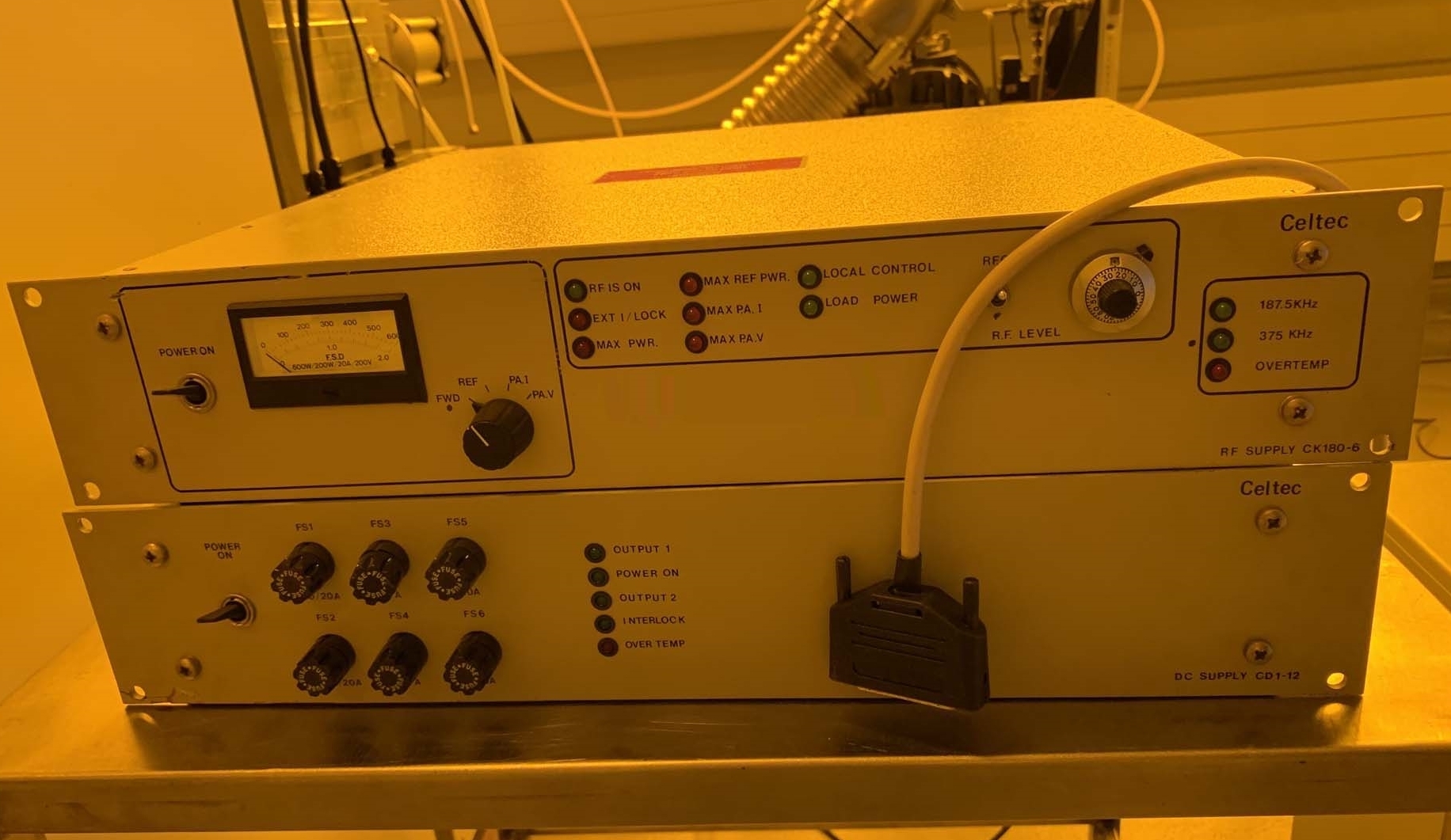

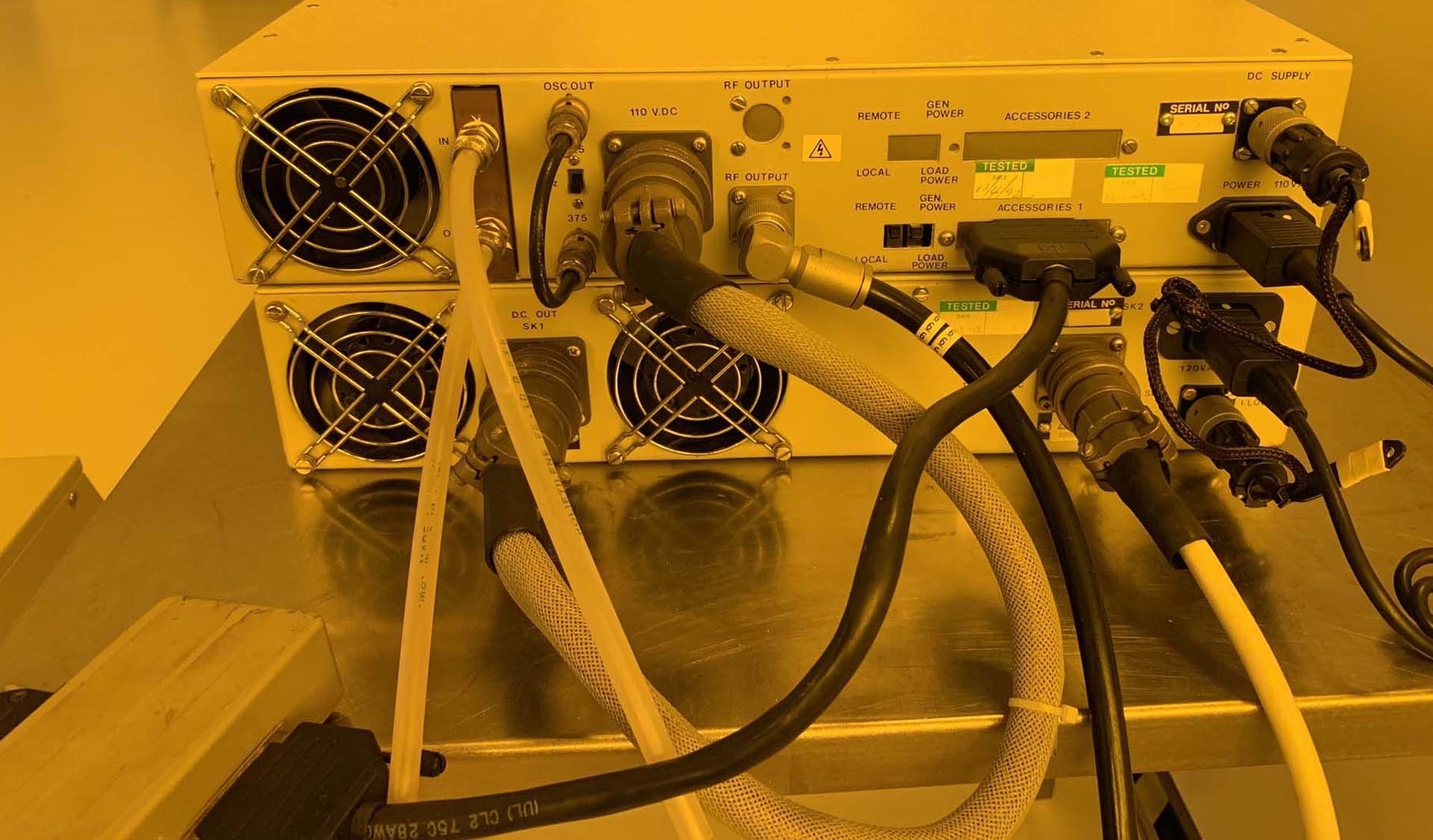

Dual frequency:

High frequency PECVD

Low frequency PECVD

RF Generator: 187.5 kHz, 375kHz

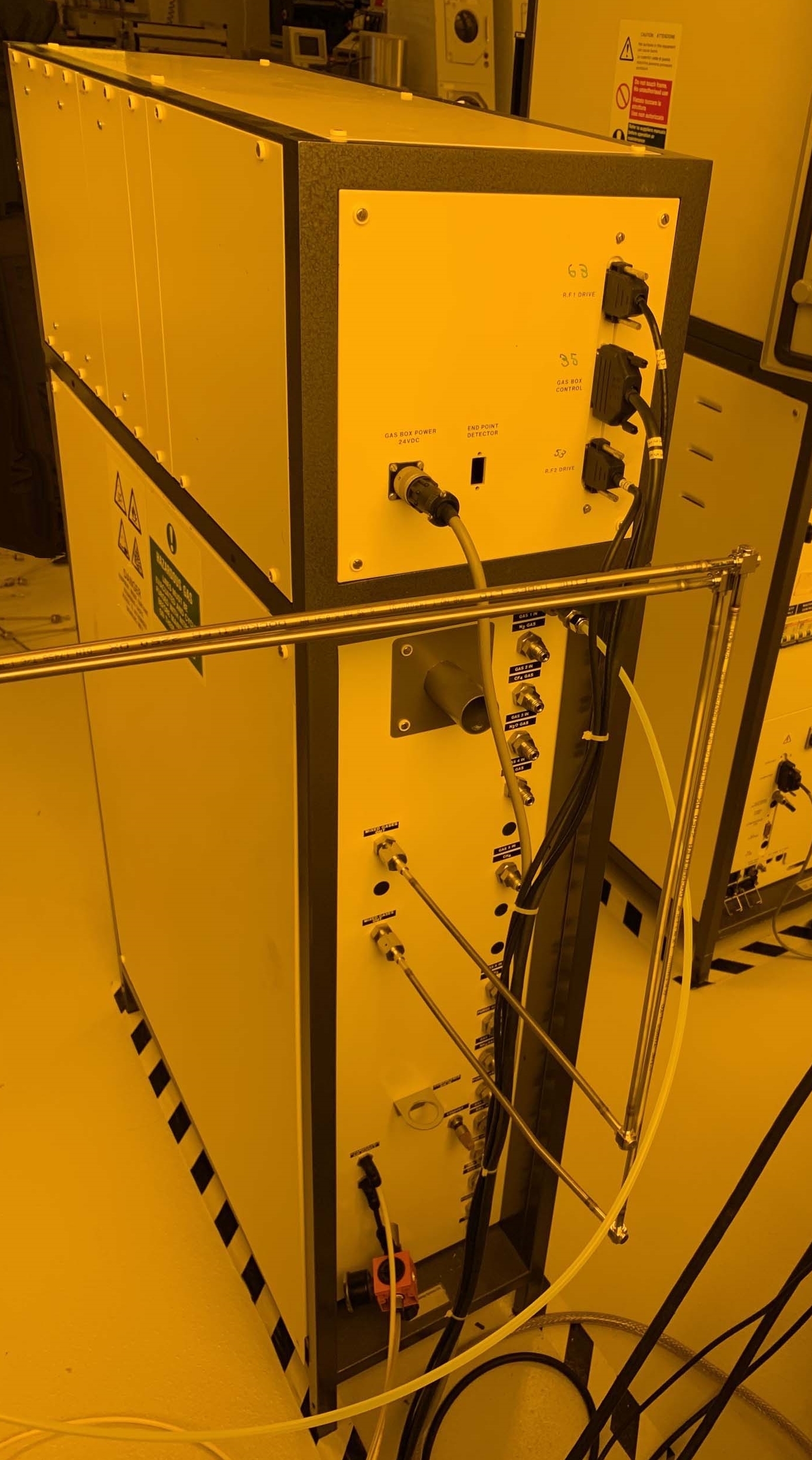

Remote gas box

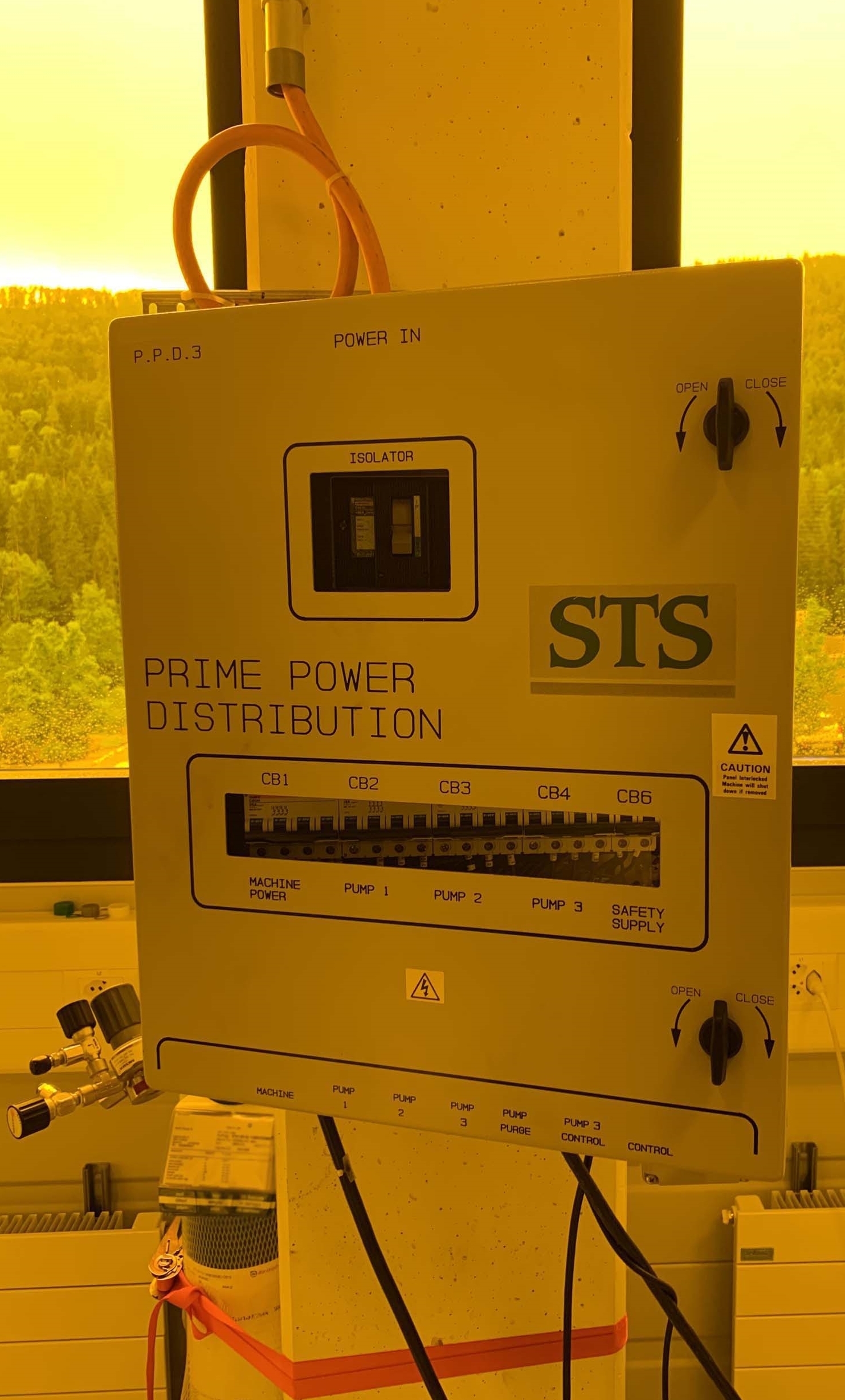

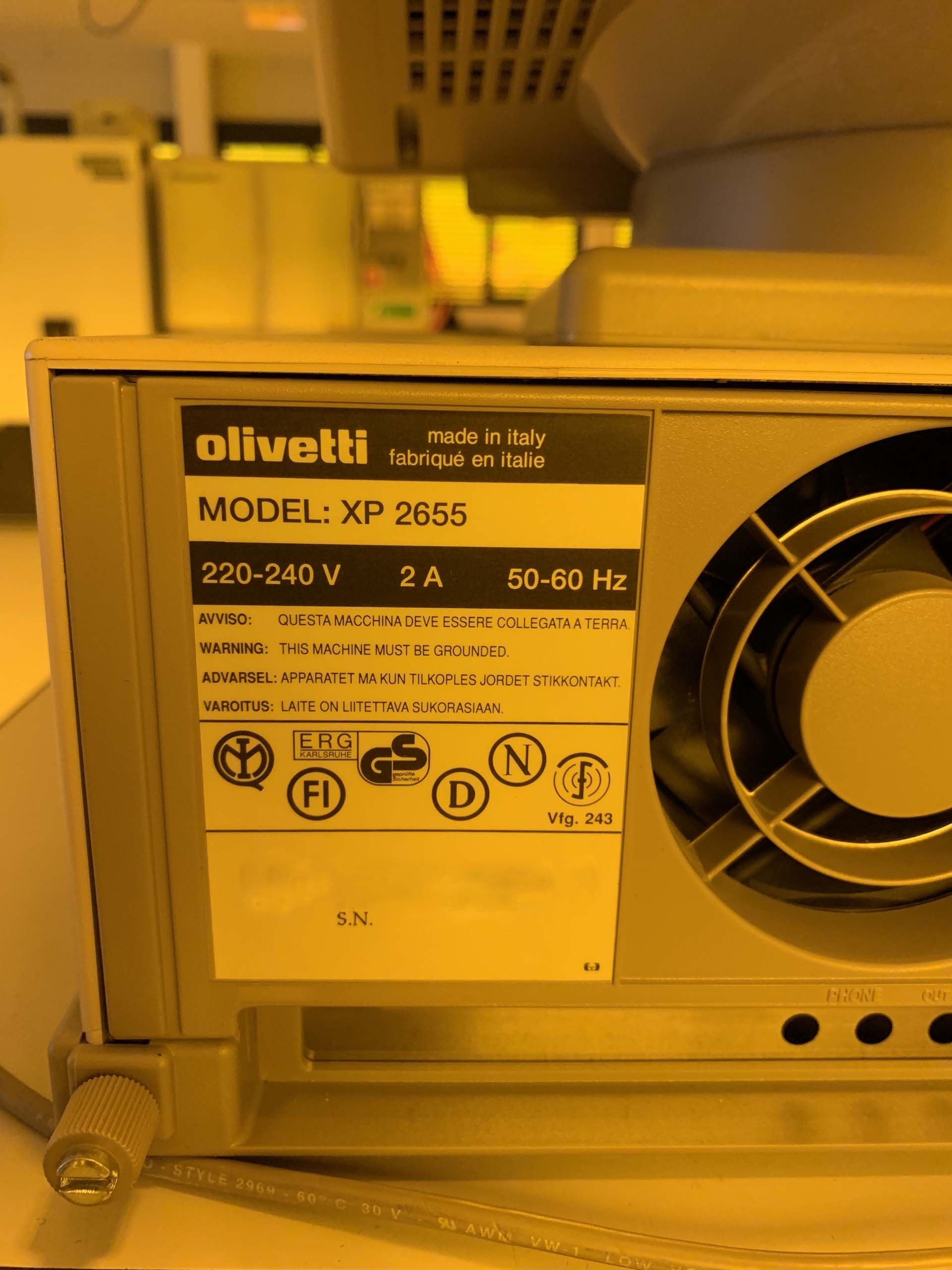

Computer

Monitor

Keyboard

Operating system: Windows 2000

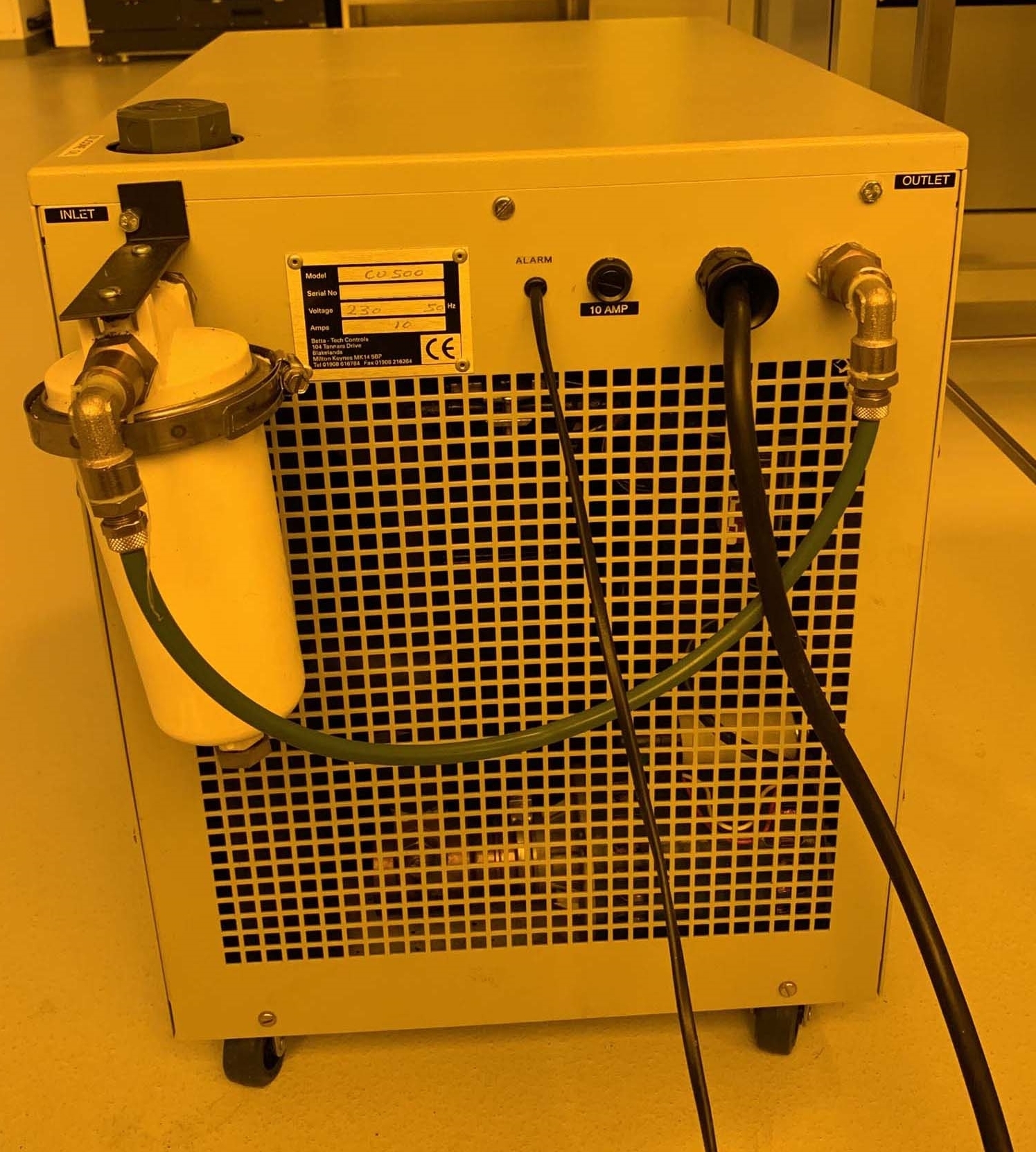

Affinity chiller

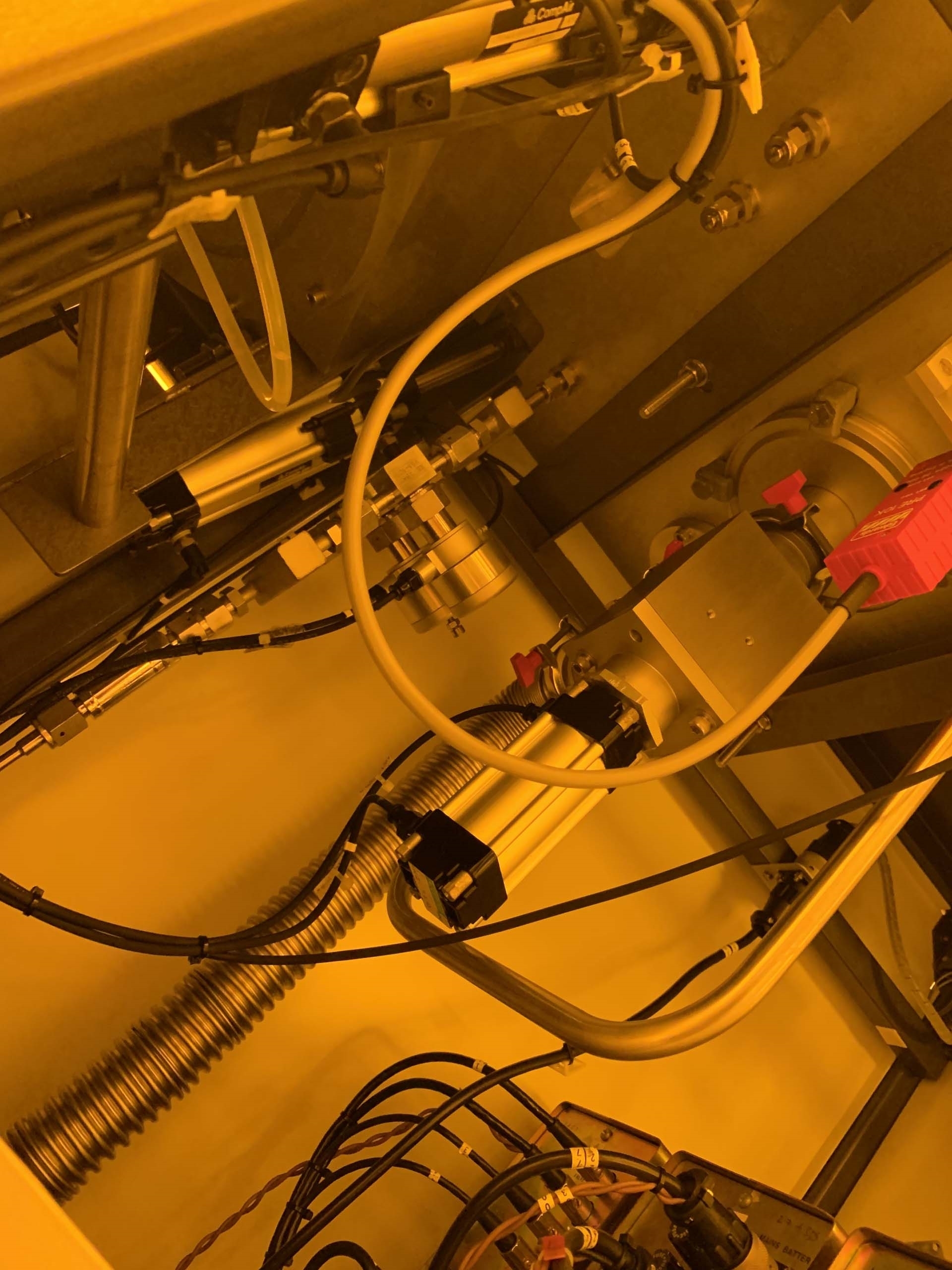

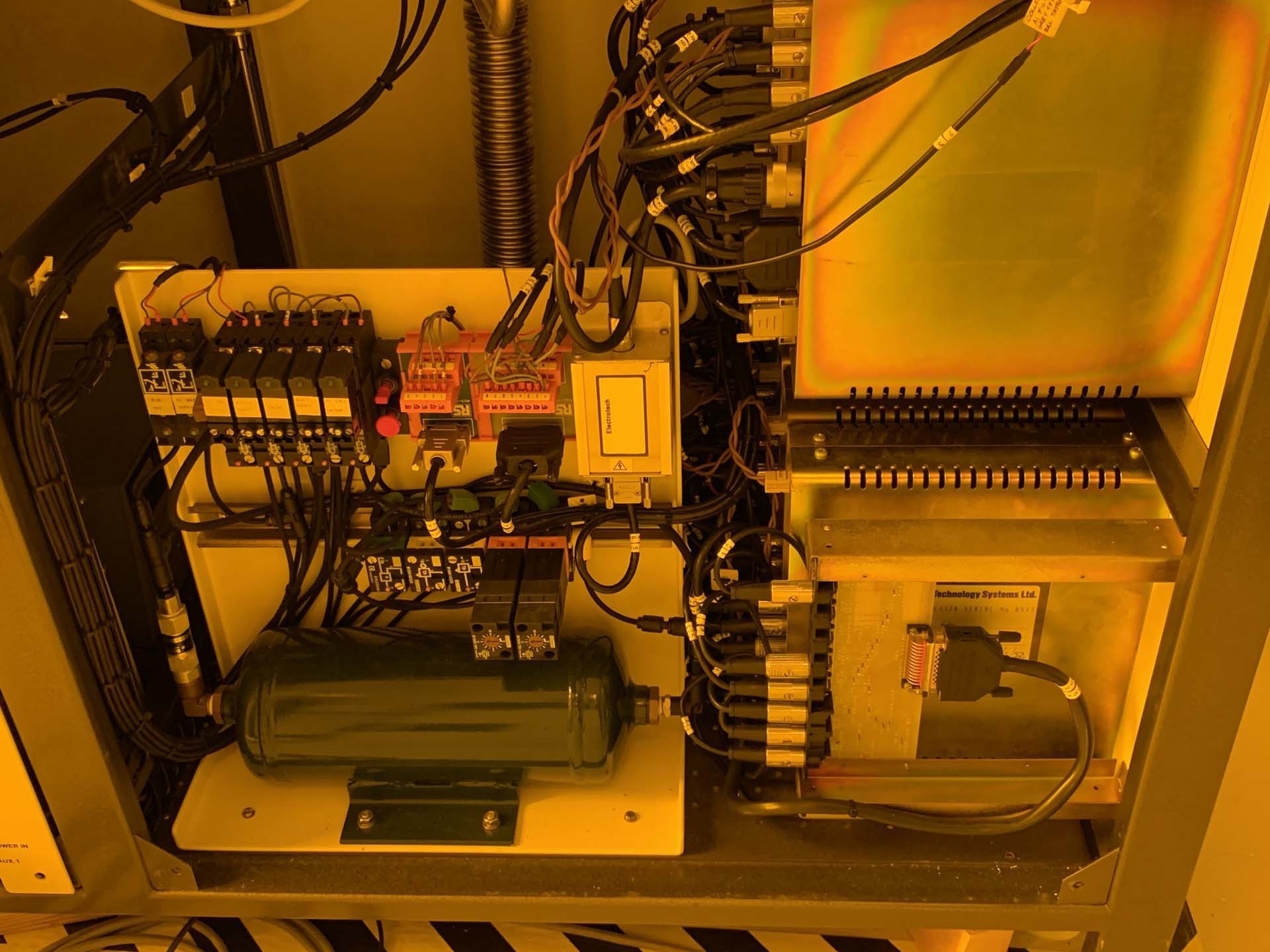

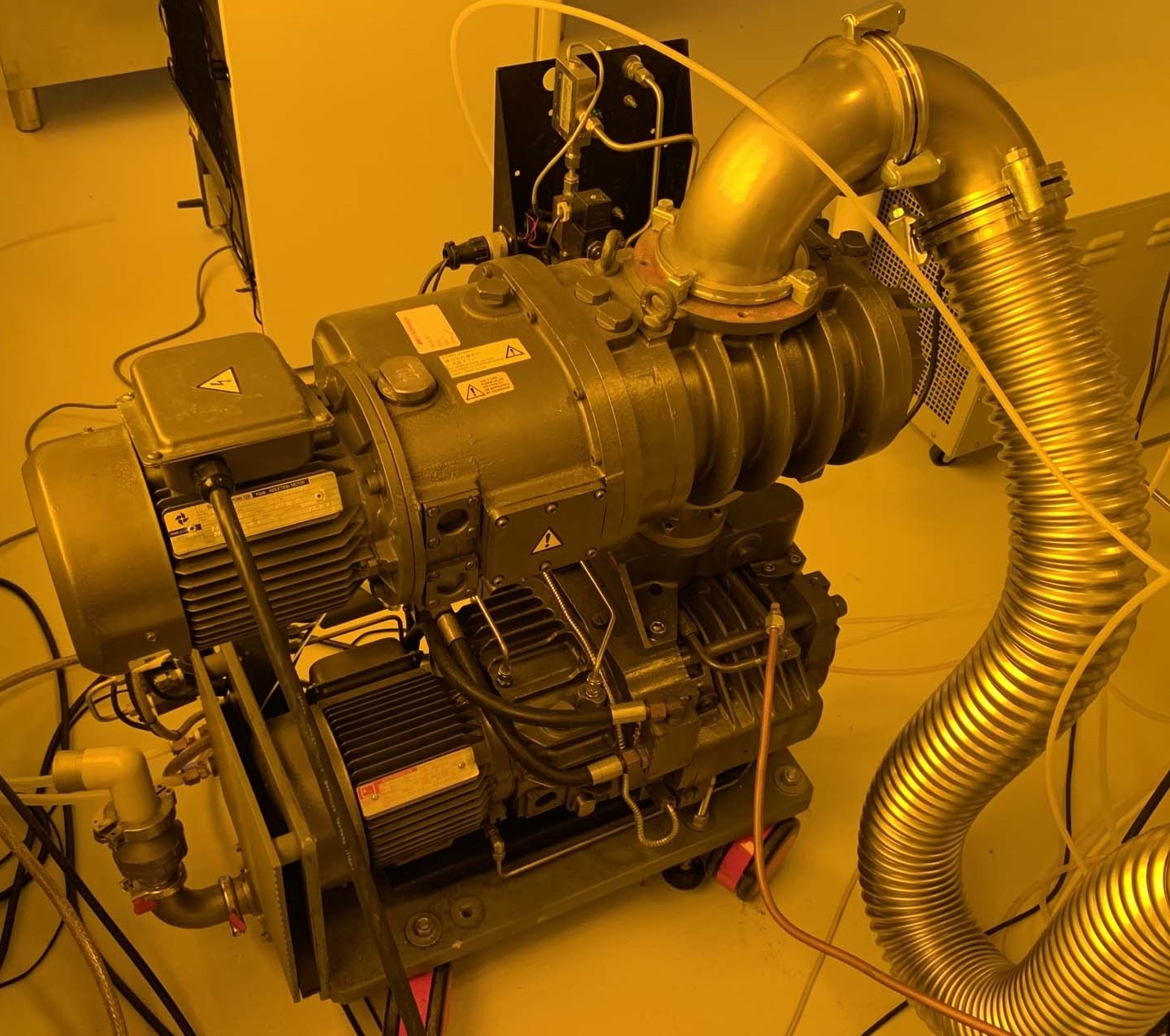

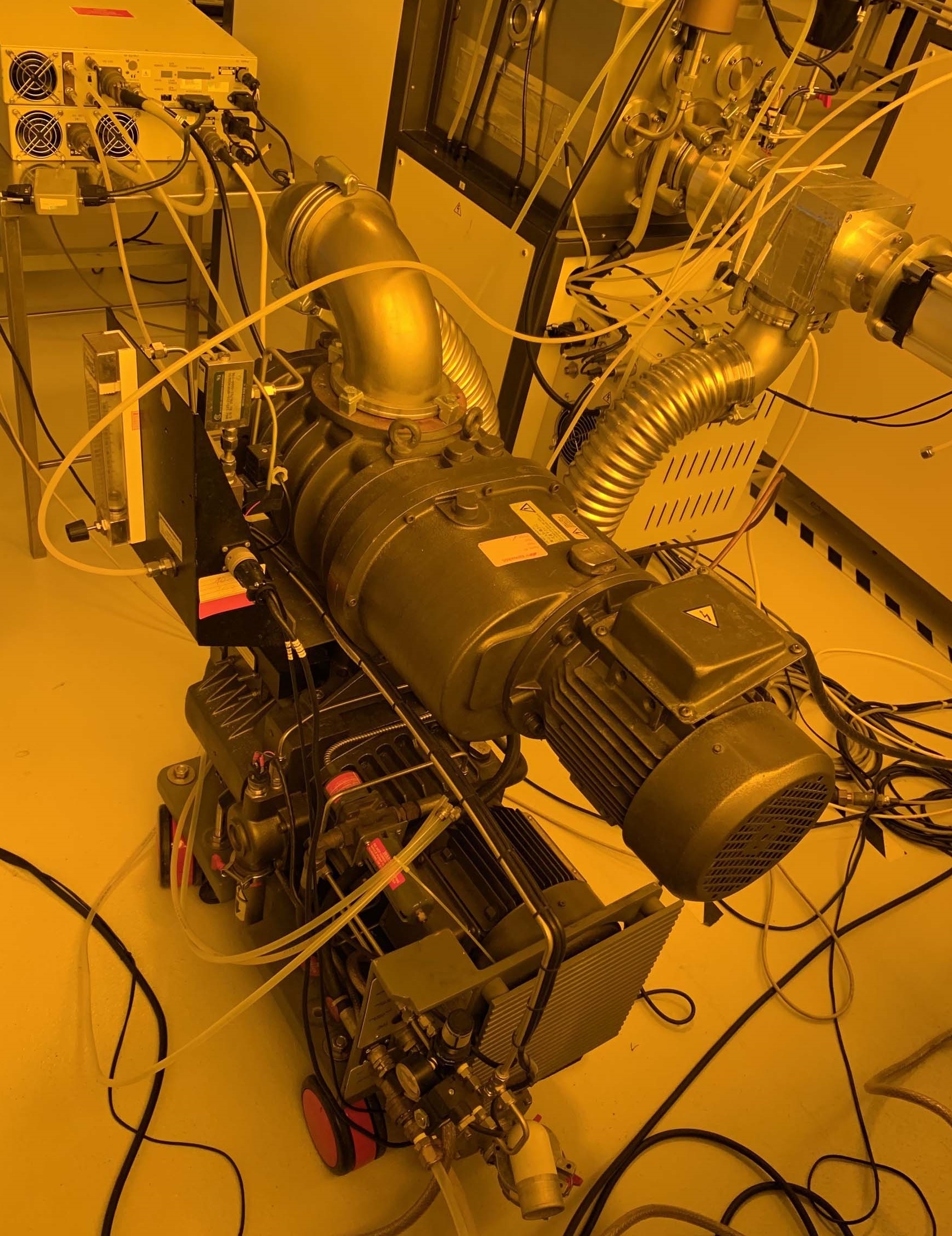

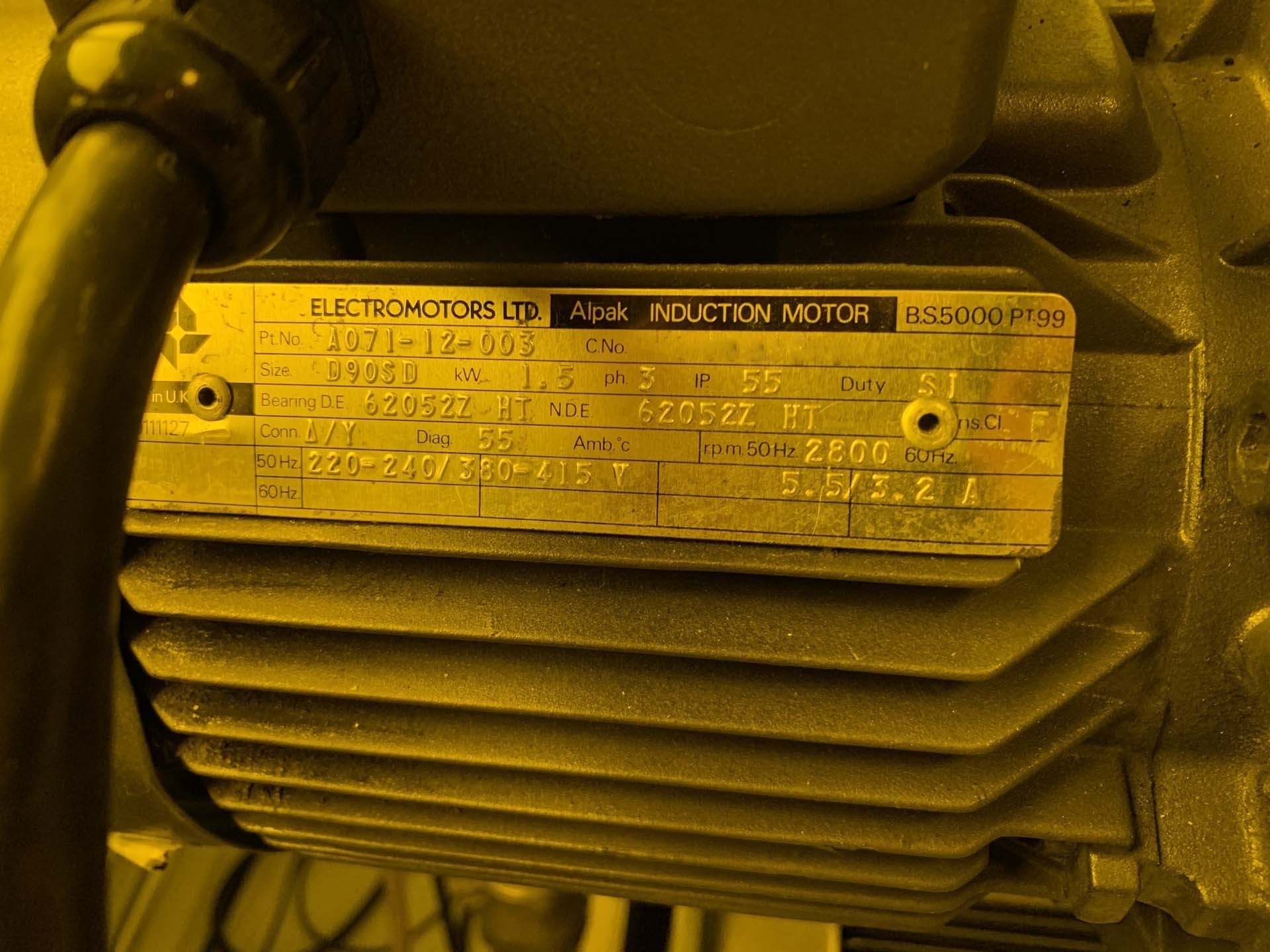

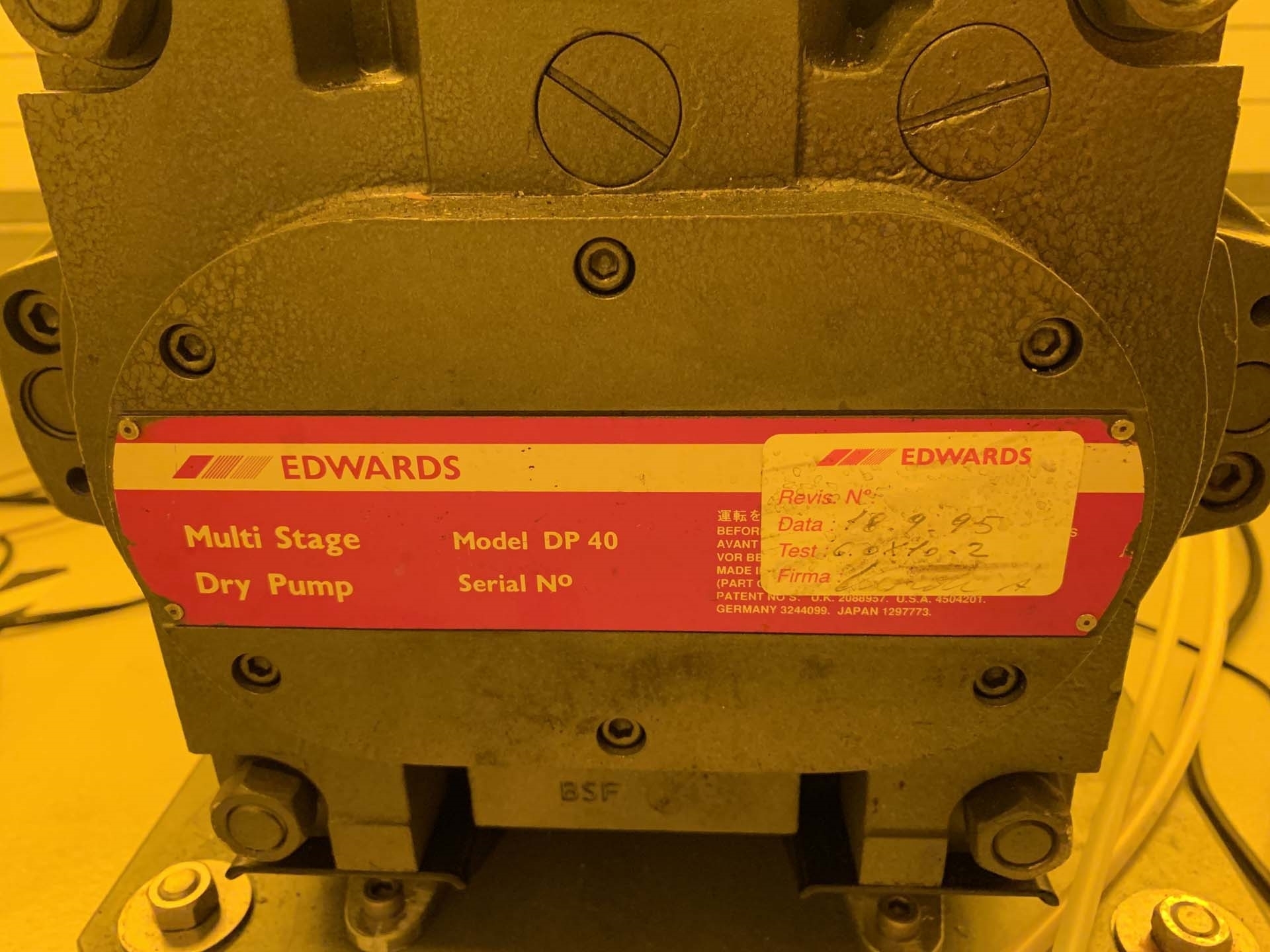

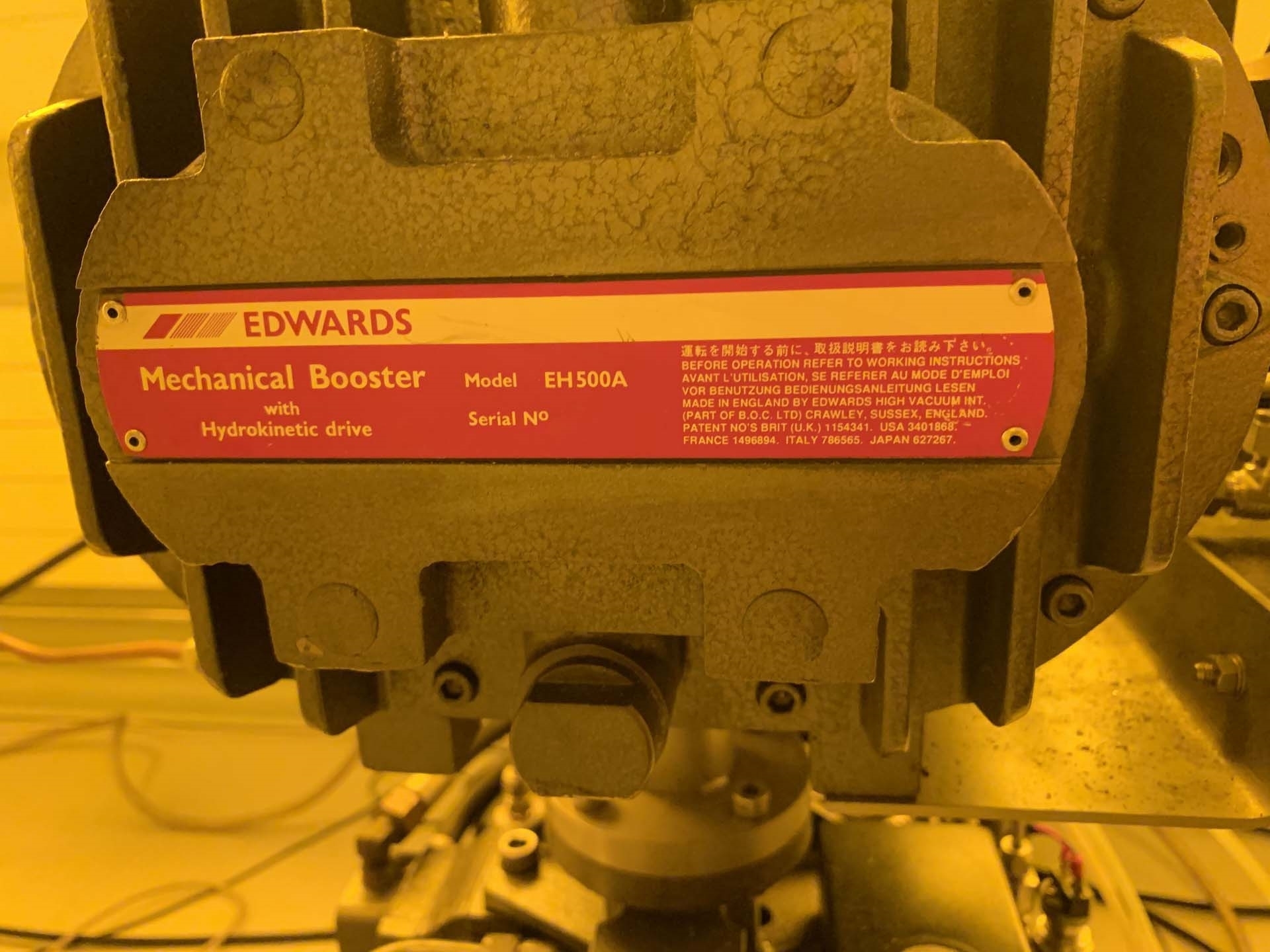

EDWARDS IH600 Vacuum pump: Chamber

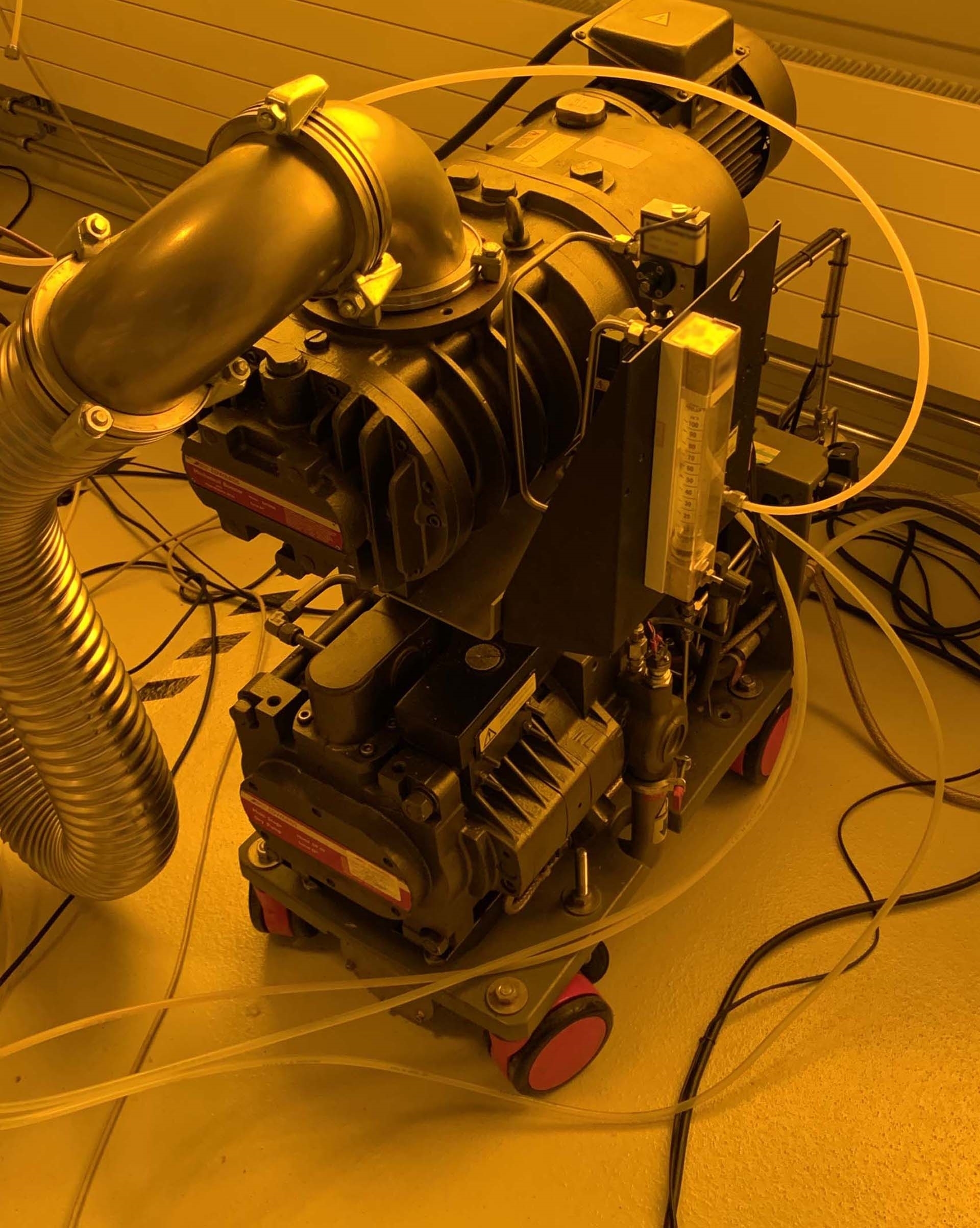

VARIAN SH-100 Vacuum pump: Load lock

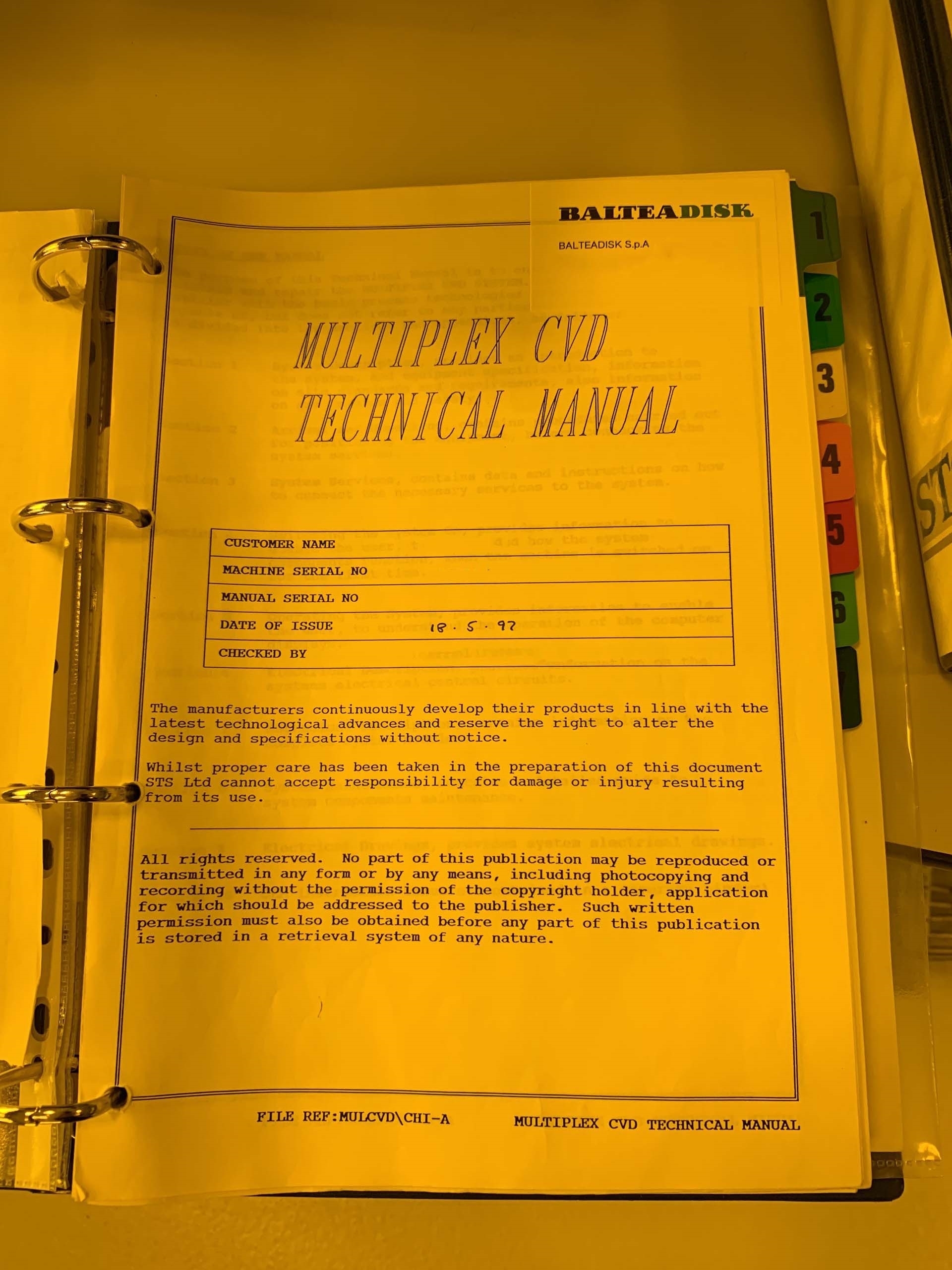

Operation manuals

Electrical drawings

Auxiliary equipment manuals

Deposit silicon dioxide (SiO2)

Silicon nitride (Si3N4)

Silicon carbide (SiC)

Gas box (Process gases):

SiH4-Ar (Silane-Ar), 100 sccm

NH3 (Ammonia), 500 sccm

N2O, 5000 sccm

N2, 5000 sccm

CF4, 1000 sccm

O2, 500 sccm

Ar, 1000 sccm

C2H2, 1000 sccm

(2) Purge lines: Silane / CH43

Manual.

STS / CPX Multiplex is a high-precision etcher-asher designed for the production of high quality microelectronic systems. The machine is based on an innovative laser process, which melts and then evaporates a thin layer of a chosen material. This allows the creation of extremely fine features on the substrate. The machine is powered by a 5-axis motion control system that ensures accuracy and repeatability, enabling it to create precise features on thin-film microcircuits. STS Multiplex is capable of producing fully etched 3-dimensional structures with depths of 0.2 to 2.0 microns and width between 0.1 and 5 microns. The machine is also capable of machining complex components with extremely fine tolerances, allowing for complete customizability. CPX Multiplex has a 4-axis robotic arm that can position the substrate at any angle, and the laser beam can be directed with precision. In addition, the machine offers a range of pre-programmed etching patterns and functions, allowing for ease of use when manufacturing higher-value components. Multiplex uses a high-powered laser to evaporate and then quickly reflow the melted material. This results in superior etching properties, producing higher-quality components more quickly than other etchers-achers. The machine is ideal for creating ultra-fine features on a wide range of materials, including metals, dielectrics, and polymers. It is also capable of producing components with very low resistance levels, which is ideal for circuits operating in high temperatures and high-frequency environments. STS / CPX Multiplex has a modular platform that allows for the customization of components, and the associated software offers a variety of tools for programming various etch processes. The machine also has an automated Part Number Programming (PNP) system that makes it easy to create complex components with intricate patterns quickly and efficiently. It is a reliable and robust device that offers a range of benefits in the production of microelectronic systems. The machine is designed to produce high-quality

There are no reviews yet