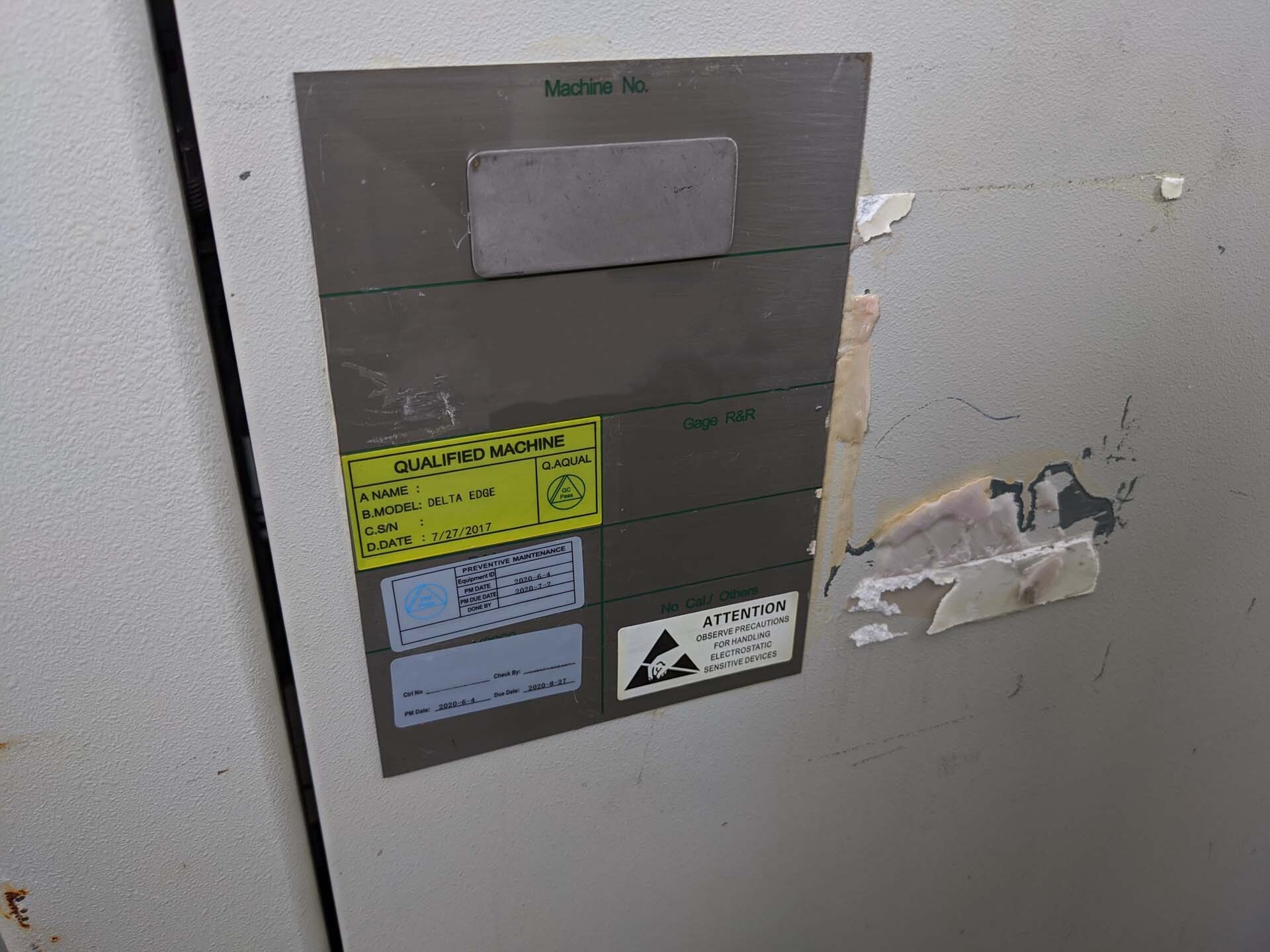

Used DELTA DESIGN Edge Gen2 #9363157 for sale

URL successfully copied!

Tap to zoom

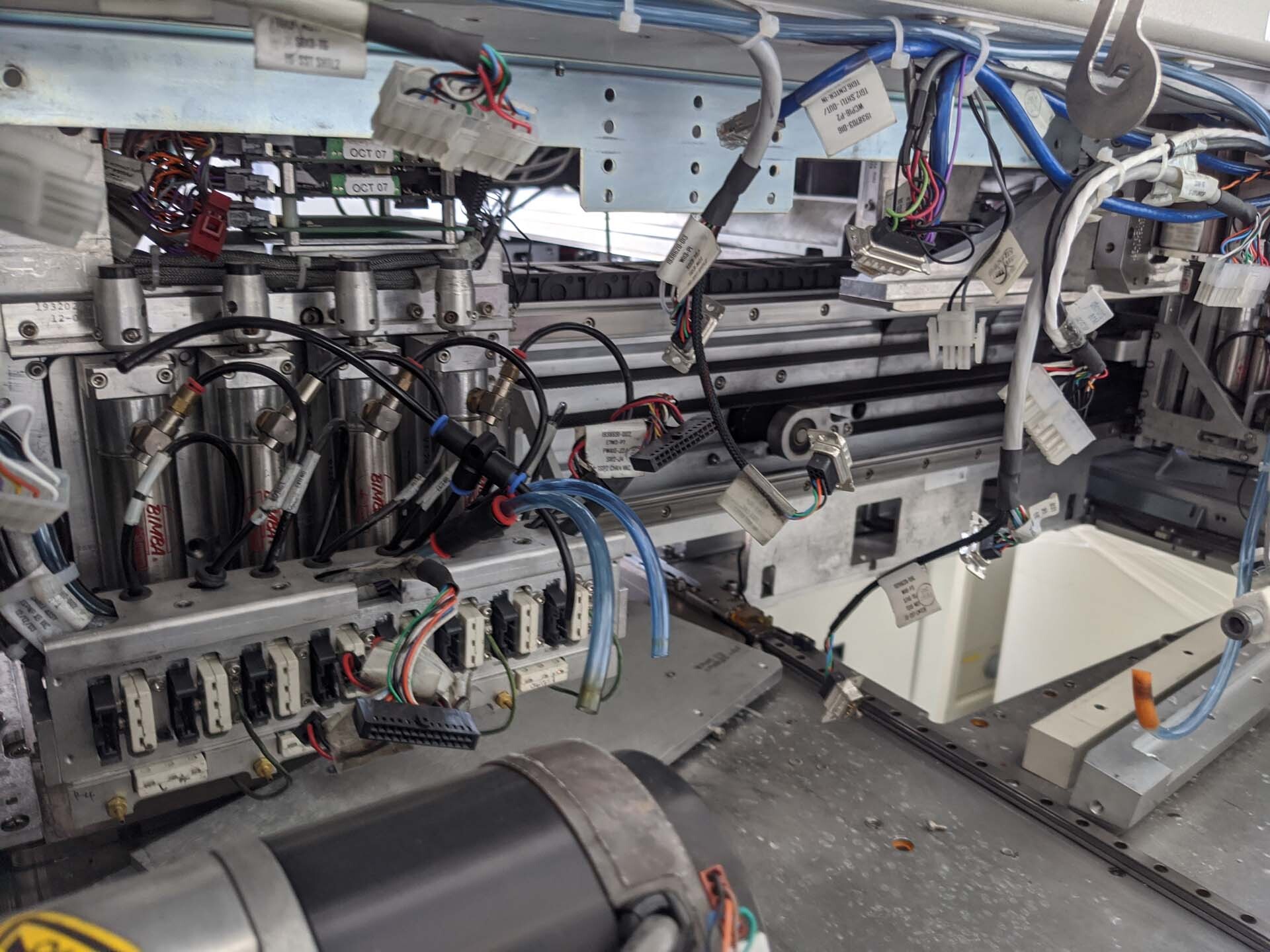

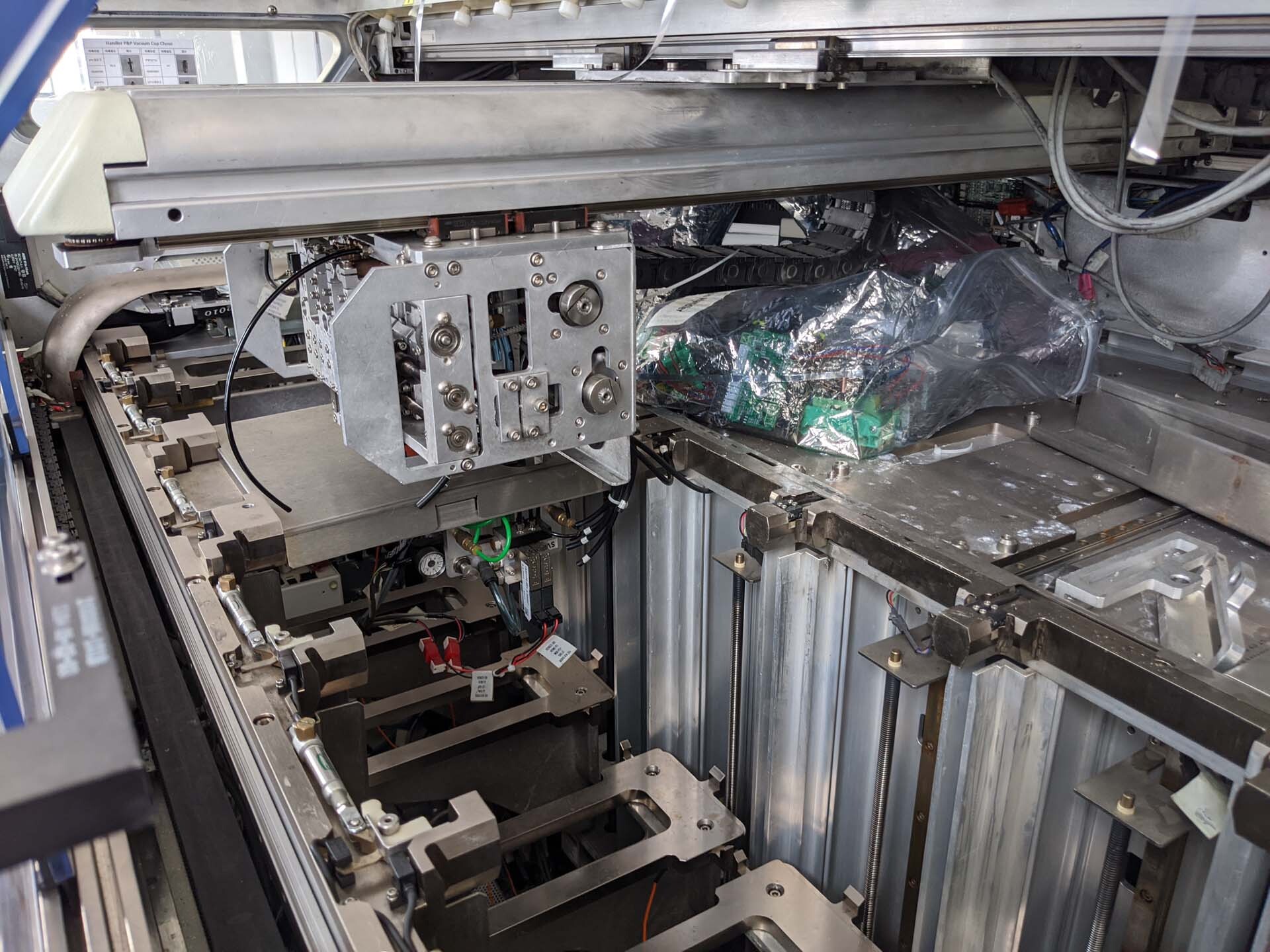

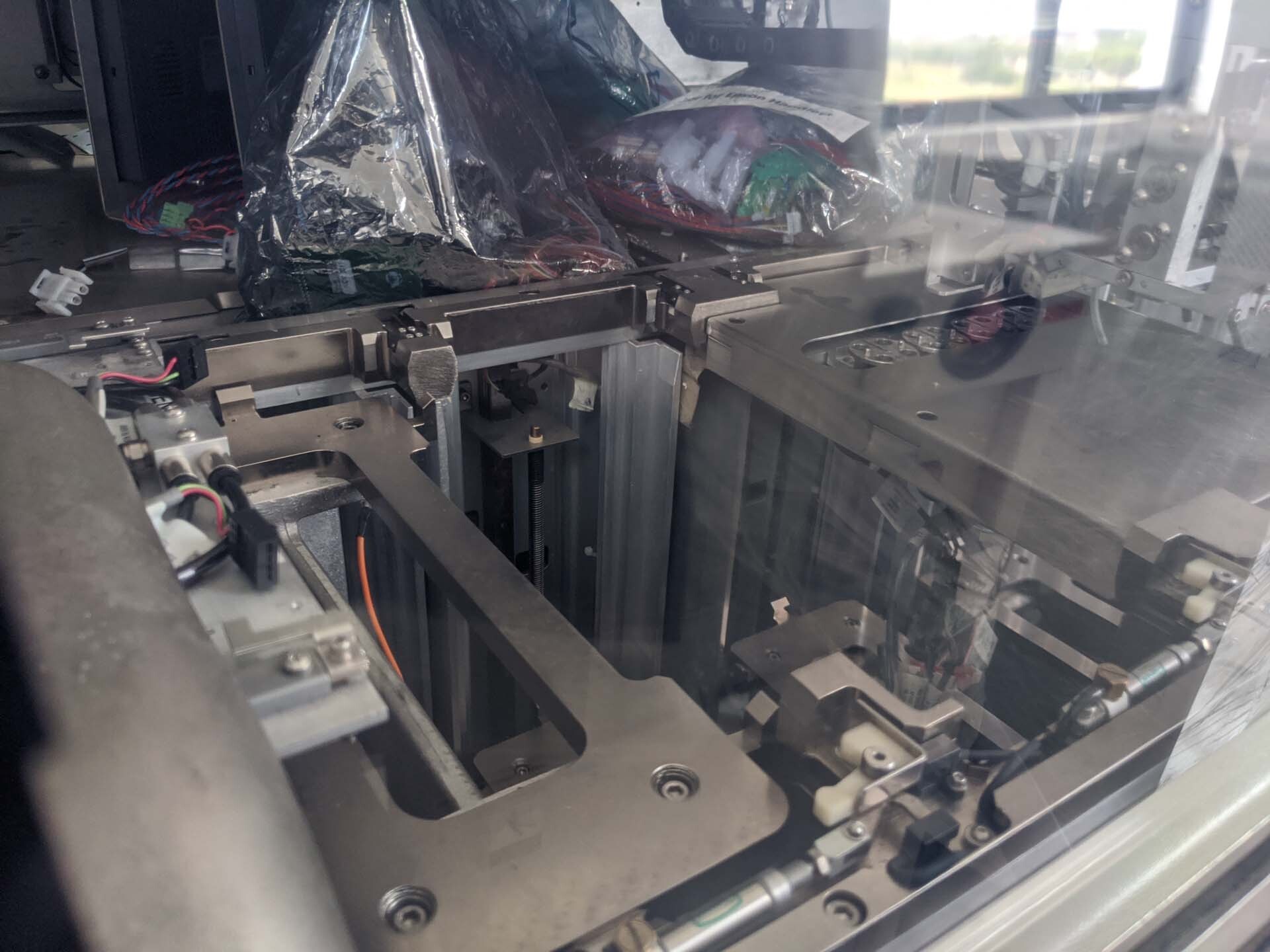

DELTA DESIGN Edge Gen2 handler is a sophisticated piece of equipment designed for highly precise, reliable, and fast assembly of small electronic components. It is a simple no-tool operator-free machine that has the capability to assemble components on a variety of substrates, such as printed circuit boards or bare panels. This versatile machine is excellent for large production runs and can fulfill a wide range of production needs in the electronics assembly process. Edge Gen2 handler comes equipped with a highly capable vision equipment with a precision inspection process, rejection mechanism, and an easy to use operator interface. The vision system features a 0.001 inch resolution camera with an impressive 8x magnification capability, able to quickly detect and reject poorly assembled or malfunctioning components. The programmable vision software allows a wide range of operations, from inspection to rework, to be accomplished in a few simple steps. In addition, DELTA DESIGN Edge Gen2 handler utilizes a patented suction nozzle designed to reduce component and substrate damage significantly while providing a reliable and grip. This high-precision operation is possible due to the use of air pressure adjustment, suction and spindle speed control, as well as a real-time sensor loop control unit. The suction nozzle design also helps ensure that components are consistently placed, and that defect rates are kept to a minimum. The handler offers an impressive maximum cycle time of 16 seconds and a maximum number of 150 components per cycle, helping to optimize the efficiency of assembly processes. It also comes equipped with an alarm machine, which can be used to quickly alert operators of potential issues. Finally, Edge Gen2 handler can be easily integrated into fully automated production systems, adding significant scalability, flexibility, and cost reduction benefits. In summary, DELTA DESIGN Edge Gen2 handler is a high-precision, reliable, and fast assembly machine for small components. It boasts an impressive vision tool, suction nozzle design, alarm asset, and is integrated into automated production systems for added scalability. Its cycle time is among the fastest on the market, and its cost-effective nature makes it an attractive option for many production processes.

There are no reviews yet