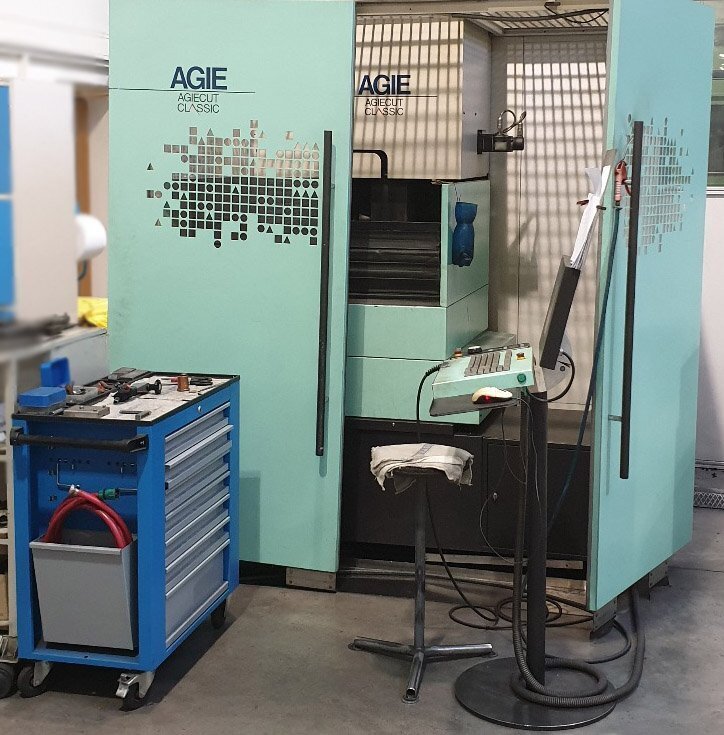

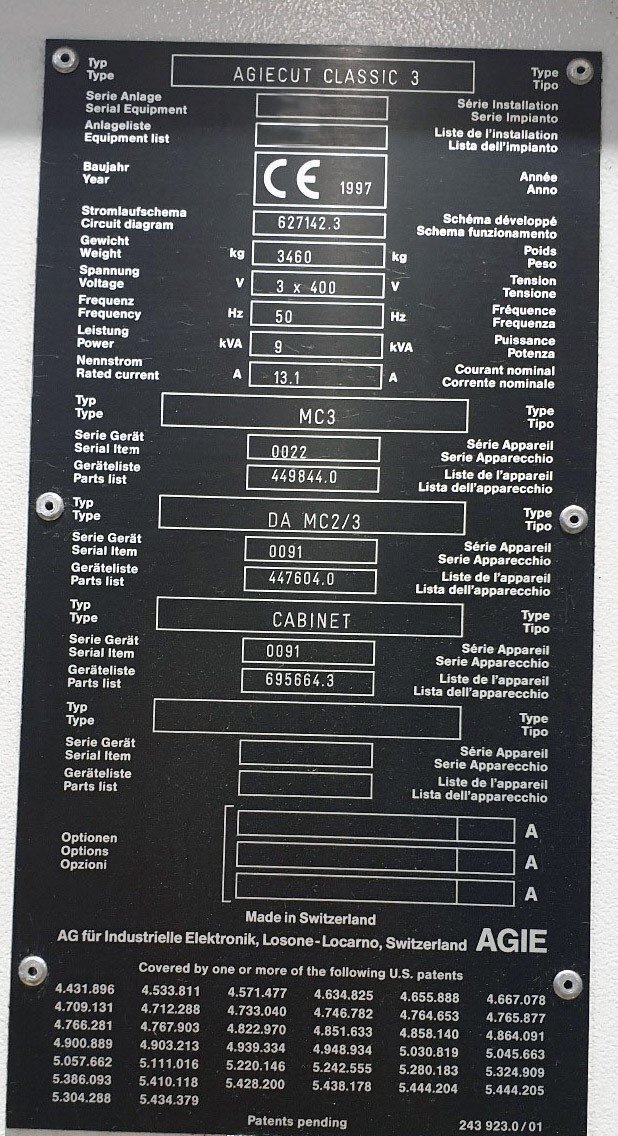

Used AGIE AgieCut Classic 3 #9302121 for sale

URL successfully copied!

Tap to zoom

AGIE AgieCut Classic 3 machine tool is a high-precision, 5-axis, CNC grinding machine designed for ultra-precise machining of complex shapes. The machine is constructed using a sturdy, cast iron base and dynamic gramer axis linear guidances to ensure accuracy and repeatability. The AgieCut features high-grade machine spindle motors to provide ample power and optimal cutting performance. The robust design has a maximum workpiece size of ø125 x 400mm and can accommodate a variety of grinding media and accessories. The AgieCut allows for complete flexibility in choice of grinding operations, with the option to use plunge, the tangential approach, or the various combinations in between. The AgieCut is equipped with the advanced EPLAN Pro CAM software for fast programming and visualization of complex grinding tasks. The intuitive user interface allows for easy programming of an almost unlimited number of grinding operations. The EPLAN Pro software also provides the flexibility to import from widely-used CAD/CAM systems like AutoCAD, SolidsWorks and MasterCAM. AgieCut Classic 3 is designed with a high degree of automation and flexibility. An optional three-axis robot can be integrated into the system that allows for automated loading and unloading of grinding media and other tools. This function reduces repetitive and tedious manual operations, as well as ensures safe handling of heavy components. The AgieCut is equipped with a number of other features that give operators greater control and accuracy. The software is equipped with a number of grinding aids, which give operators greater freedom in optimizing the grinding process. The Aquapore coolant system helps reduce thermal shock during grinding and ensures optimum cooling of the cutting edges. The machine also has a self-learning process for automatic grinding wheel adjustment and automatic recognition of machining parameters. For maintenance, the machine is designed with easy access to all its components, making inspection and repair quick and easy. An optional vibration monitoring system monitors the dynamic behavior and vibration levels of the machine for early machine and tool wear detection, thus increasing the machine reliability and accuracy. AGIE AgieCut Classic 3 provides an advanced solution for intricate applications. Its rigid construction, advanced software and automation capabilities, and numerous features make it the perfect choice for accurate, efficient, and cost-effective processes.

There are no reviews yet