Used DMG DMC-635V #293655090 for sale

URL successfully copied!

Tap to zoom

ID: 293655090

Vintage: 2013

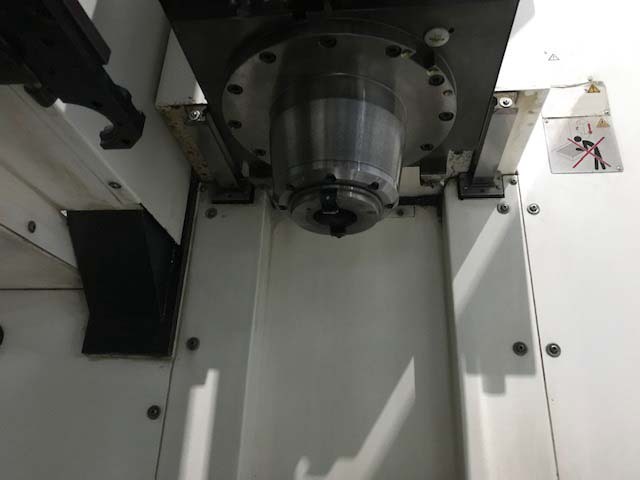

Vertical machining center

Table size: 790 x 560 mm

Max load weight: 600 kg

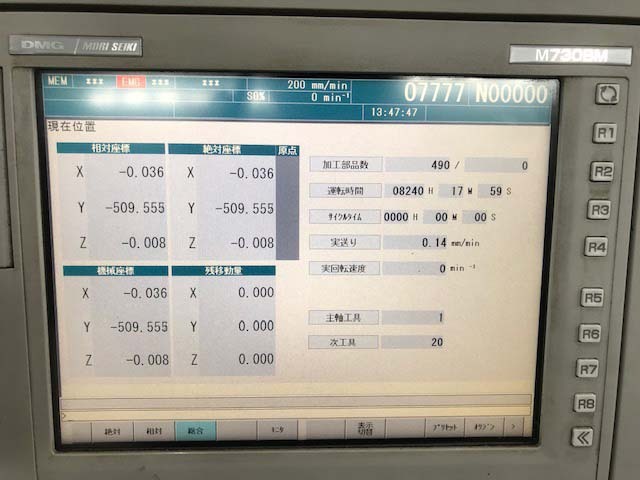

Stroke (X, Y, Z): 635 x 510 x 460 mm

Spindle speed: 8000 rpm

Spindle bearing inner diameter: 65 mm

Spindle end to table top: 120 x 580 mm

Control: M735BM (MAPPS)

BT40

ATC: 20

2013 vintage.

DMG DMU-635V is a 5-axis vertical machining center (VMC) that offers superior speed and accuracy. It is equipped with a high-precision direct-drive spindle, providing superior dynamic performance and superior cutting accuracy compared to conventional belt-driven spindles. The direct-drive spindle has a maximum speed of 12,000 rpm, and can support a range of cutting tools up to 12mm diameter. The direct-drive spindle also offers superior vibration suppression, providing greater stability and accuracy when machining complex parts. DMG DMU-635V is designed for reliable and productive machining of large parts with 5-axis machining capabilities. Its main structural components are made of thermal-treated cast iron, contributing to superior thermal stability and extended die life. The machine has a maximum working table of 1,400 mm × 700 mm and a maximum tool length of 650 mm. It is capable of achieving feedrates up to 40 m/min and rapid traverse rates up to 60 m/min. The machine is also equipped with a high-performance cooling system and a climate-controlled internal cooling cylinder, further increasing its accuracy and machining efficiency. DMG DMU-635V is equipped with an SIEMENS-controlled spindle, providing users with advanced control over the process. The control features a range of control functions, including programmable spindle speed, automatic tool change, graphical programming, and an easy-to-use interface. Additionally, the machine is also equipped with a range of safety features, including a door safety switch, a self-monitoring system, an automatic detection system, and an emergency door latch. DMG DMU-635V is designed for a wide range of machining applications, making it suitable for a variety of industries, such as mechanical and aerospace engineering, automotive, and medical. Its superior accuracy and speed make it a great choice for complex machining operations, and its high levels of accuracy and repeatability make it suitable for precision machining tasks. Its easy-to-use operator control panel and range of user-friendly safety features make it an especially attractive machine for busy production lines.

There are no reviews yet