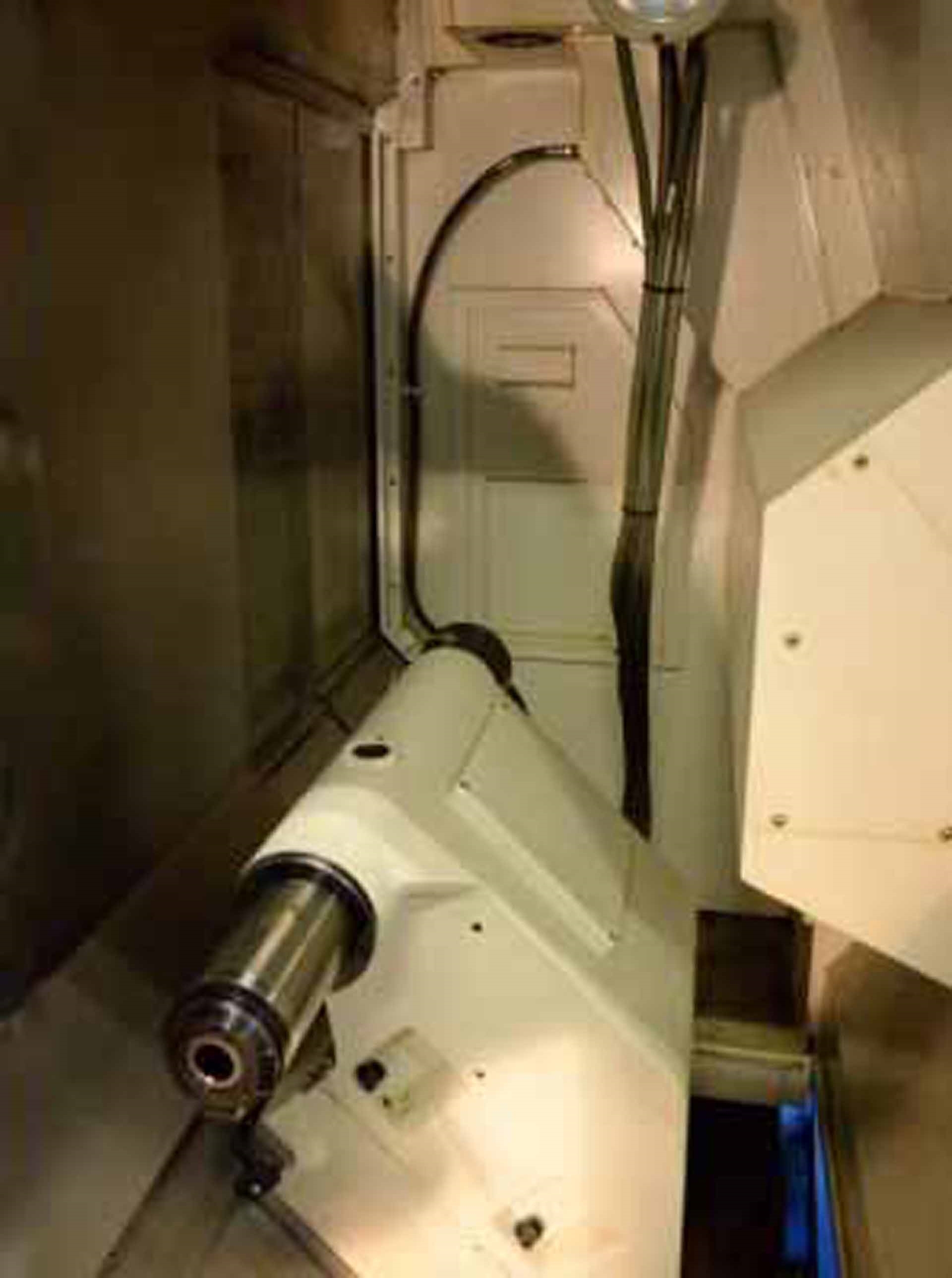

Used DOOSAN MECATECH PUMA MX 3000 #9224001 for sale

URL successfully copied!

Tap to zoom

ID: 9224001

Vintage: 2006

CNC Turning / Milling center

(5) Axes

Spindle

Main spindle

Spindle nose: A2-8

Spindle power: 30 / 25 kW

Spindle speeds: 3.000 rpm

Maximum bar diameter: 86 mm

Maximum turning diameter: 540 mm

Maximum diameter on bench: 750 mm

C Axis indexing precision: 0.001°

Turning-milling spindle:

X/Z Stroke: 555 / 1.595 mm

Y Stroke: +/- 80 mm

B Axis stroke: +/- 120°

B Axis indexing precision: 0.001°

Tool type: CAPTO C6

Spindle speeds: 10.000 rpm

Spindle power: 15 kW

Tool changer:

Automatic tool changer type: Loading arm

Tool magazine capacity: 40

Tool exchange time: 1.5 Sec

Tailstock:

Tailstock type: Automatic

Type of cone: MT4

Quill stroke: 150 mm

Distance between centers: 1.520 mm

Machine hours:

11,468 hours under power

Working hours: 4,337

Spindle hours: 2,735

Equipment:

CNC: FANUC 18i-TB

Interactive programming: Manual guide

Connector: RJ45 / PCMCIA / RS232

Tool corrective: 400

Memorable part origins: 6

Electronic hand wheel

3 Colors status lamp

Coolant tank

With high-pressure pump: 20 Bars

Chips conveyor

Spindle cooling unit: Turning and milling

Electric transformer: 400 / 230 V

Tool probe

Predisposition for bar feeder

Chuck 3 jaws: SMW AUTOBLOCK KNCS-N-340-117

Power supply:

Supply voltage: 200 V

Total installed power: 65,26 kVA

2006 vintage.

DOOSAN MECATECH PUMA MX 3000 is a highly-versatile machine tool that can help bring maximum productivity to a wide variety of industrial applications. It is designed to enable operators to quickly and easily fabricate the most complex parts with high accuracy and speed. PUMA MX 3000 is the most advanced in the PUMA series and offers unprecedented performance thanks to its advanced technology and features. DOOSAN MECATECH PUMA MX 3000 is built on a rigid, high-quality cast-iron frame that provides excellent thermal stability and adequate support for the spindle. This is complemented by a high-precision roller-bearing X and Z axes for smooth and precise movements. The combined effect of these features enables the machine to perform highly intricate operations with minimum vibrations. At the heart of PUMA MX 3000 is an FANUC 0iMD series CNC control. This allows the operator to program and control the machine's movements with utmost precision. There are multiple sensing and feedback functions that can be utilized by the operator to detect discrepancies and take corrective action. The touchsceen monitor also makes it easy to visualize programs and adjust settings. In terms of machining, DOOSAN MECATECH PUMA MX 3000 offers a fast and smooth cutting performance. It comes with a 20 HP high precision spindle that delivers speeds up to 5000 RPM. It also boasts a fast rapids speed of 28 meters per minute along each axis for enhanced productivity. In addition, it is equipped with a 24-tool automatic tool changer that can quickly switch between tools, allowing for continuous machining operations. When it comes to safety, PUMA MX 3000 is designed to meet the most rigorous safety standards. The spindle area is equipped with a protective cover that prevents access to moving parts. Additionally, an emergency stop button is located on the control panel for easy access. The machine also comes with an overload protection system that can detect dangerous levels of torque and automatically shut down to prevent any damage. Overall, DOOSAN MECATECH PUMA MX 3000 is a highly-versatile machine tool that offers superior performance and can help take your operations to the next level. It is packed with advanced features and technology that allow the operator to quickly fabricate intricate parts while ensuring the utmost efficiency, accuracy, and safety.

There are no reviews yet