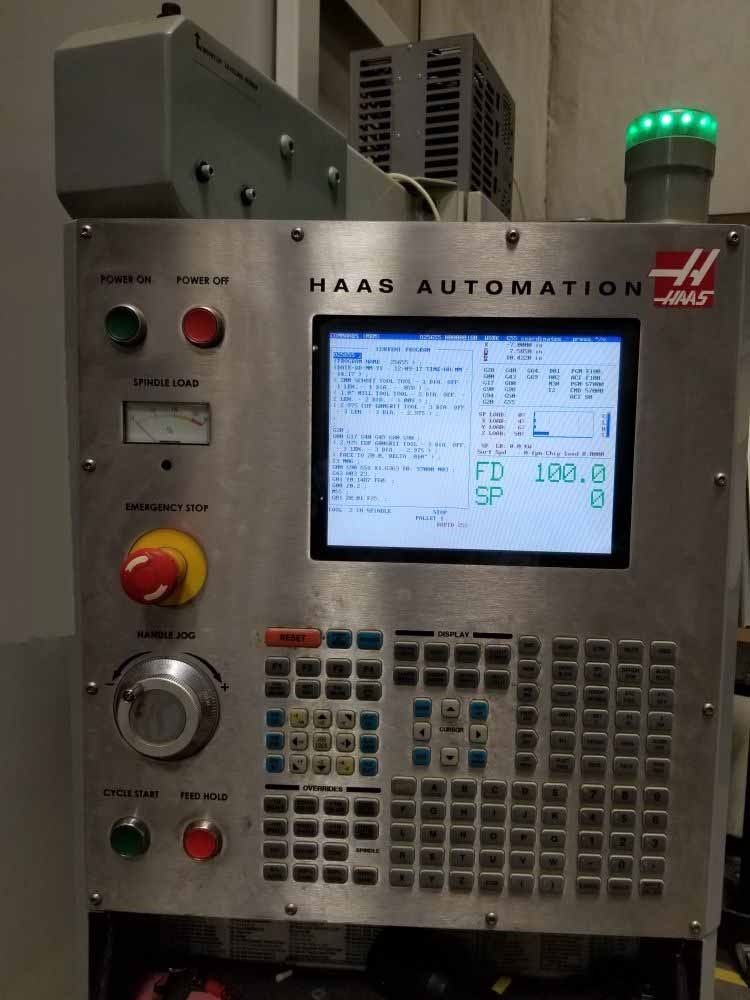

Used HAAS MDC-500 #9194504 for sale

URL successfully copied!

Tap to zoom

ID: 9194504

Vintage: 2006

Milling / Drilling center

Table size: 20" x 12.75"

Rapid traverse rate: 1000" / Min

Spindle taper: CAT 40

Spindle speeds: 15,000 RPM

Spindle torque: 75 Ft Lbs @ 1400 RPM

Spindle motor: 20 HP 3/60

Tool change time:

Tool to tool: 2.2 Seconds

Chip to chip: 4.8 Seconds

Travels:

X-Axis: 20"

Y-Axis: 14"

Z-Axis: 20"

Includes:

HAAS CNC Control

(2) 4th-Axis interface to run rotary indexer on each table

24-Position side mounted automatic tool changer

Through spindle coolant

15" Color LCD monitor

Rigid tapping

(2) Pallets

2006 vintage.

HAAS MDC-500 is a high performance machine tool designed for precision and accuracy. It features a modern milling column which can be fitted with a wide variety of spindles and accessories to meet specific production requirements. The machine has a five-axis spindle design which allows for simultaneous multiple axes interpolation, shortening cycle times. The tool offers a high speed spindle which runs up to 12,000 RPM, a 5HP drive motor, a high tech spindle liner, and optional coolant through-spindle and workpiece. HAAS MDC 500 has a robust construction with a frame and column made of welded aluminum, where each bench is CNC machined from billet aluminum for a perfect fit and finish. The rigid design ensures stability and allows for maximum performance. The control system used in MDC-500 is a 2-axis Heidenhain Digital readout system with a built in ladder logic programming system for precise motion control of the 3-axis interpolating cutting. The controller can be integrated with a PLC for automated production. It can also be connected to a DNC cutting machine over Ethernet for unmanned operation. MDC 500 features an optional slant-bed design designed to improve part accessibility reducing non-cutting time and allowing longer part runs. The offset design also produces a better surface finish, while extremely tight tolerances can be achieved using HAAS Method of Optimizing configuration. Other features on HAAS MDC-500 include a high speed cutting algorithm for fast acceleration/deceleration times and a built-in threading companion program for case and chamfer threading. An appropriate lubricant is recommended for long cutting tool life, and a comprehensive list of safety protocols must be followed for safe operation. HAAS MDC 500 is an ideal machine for precision machining and milling production, offering maximum accuracy and repeatability with minimal setup time. Its modern design and superior technology make it an excellent choice for any production environment.

There are no reviews yet