Used HAAS SL-30T #9093216 for sale

URL successfully copied!

Tap to zoom

ID: 9093216

Vintage: 2004

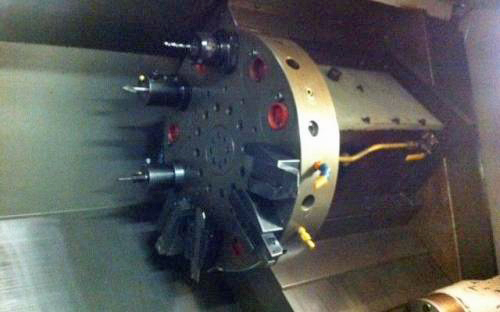

CNC lathe

Chuck Size 10"

Max Diameter Bar Capacity 3"

Max Swing Over Bed / Carriage 30" / 14.5"

Max Turning Diameter 17"

Distance Between Centers 39"

Max Machining Length 32"

Tools 12

Spindle Motor 40 / 30 HP

Spindle Speed 20 - 3400 RPM

Spindle Bore 3.5"

Spindle Nose A2-6

Spindle Torque 300 ft. lbs.

Rapid Traverse Rates (X & Z) 710 IPM

X-Axis Travel 11.3"

Z-Axis Travel 34"

Tailstock Taper MT#4

HAAS CNC CONTROL

12" Color LCD

10" Hydraulic Chuck

Collet Chuck

Programmable Hydraulic Tailstock

Tool Presetter

Auto Parts Catcher

Haas Servo Bar 300 Short Magazine Barfeed

3.5" Floppy Disc Drive

2004 vintage.

HAAS SL-30T is a large-frame, high-speed, high-performance machine tool designed for complex machining tasks, such as milling, turning, and grinding of large parts. It utilizes both conventional and custom designs for its components. SL-30T is equipped with an integrated control package including a built-in HAAS control and a 17" LCD touch screen that provides equipment navigation, programming, and diagnostic capabilities for monitoring and controlling machine operation. The spindle features a two-speed design that allows for a maximum spindle speed of 12,000 rpm, and a maximum acceleration of 1G. This makes HAAS SL-30T suitable for high-speed machining of complex parts and components. The column is constructed from cast-iron components and features extra-rigid webs, an extended Z axis travel, box-in-box construction and a machined Y axis dovetail for superior stiffness and precision over the entire table area. SL-30T has a large Table Size for up to a 4-sided machining of workpieces up to 746 mm x 573 mm and a maximum part weight of 500 kg. HAAS SL-30T is equipped with intuitive programming technology such as the Windows-based "Fanuc Programming" language and the Machine System Software that make operations easier and reduce setup times. It also offers a fully integrated tool management unit, HAAS Ethernet device networking (HEDN), and secure data exchange with off-site locations. SL-30T is also equipped with various other features designed for operator comfort and convenience, including a hydraulic counterbalance machine for protecting components from shock loads and a 3rd-generation cooling tool featuring a low noise and high-efficiency turbo asset. Overall, HAAS SL-30T provides a combination of precision, efficiency, and power that makes it suitable for demanding machining applications. Its robust construction and reliable design provide users with an unmatched level of performance and agility. Combined with its wide range of features and intuitive control systems, SL-30T is an ideal choice for high-speed machining operations in any manufacturing environment.

There are no reviews yet