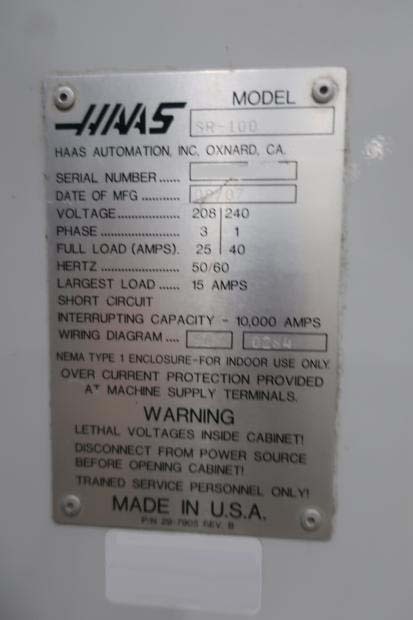

Used HAAS SR-100 #293671019 for sale

URL successfully copied!

Tap to zoom

ID: 293671019

Wafer Size: 4"-8"

Vintage: 2007

CNC Router, 4"-8"

(3) Axis:

X-Axis travel, 100"

Y-Axis travel, 52"

Z-Axis travel, 8"

CNC Control

Table size: 96" x 48"

Distance between columns: 62.5"

Distance spindle nose to table top: 3" - 11"

HSD Spindle speeds: 0 - 24000 RPM

Spindle taper: 30 ISO

Spindle motor: 5 HP

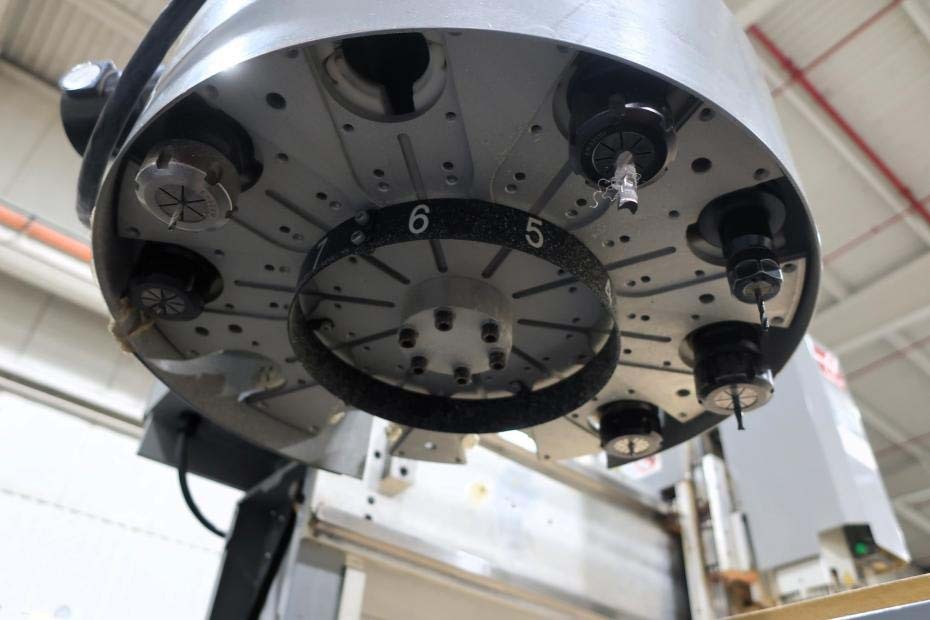

Tool magazine capacity: 10-Station tool changers

Rapid traverse rates (X, Y, Z): 2000, 2000, 590 IPM

Cutting feed rates: 1,000 IPM

2007 vintage.

HAAS SR-100 is a high-speed, multi-spindle, machine tool used for a wide range of automatic production applications. The machine is particularly suited for high-speed drilling and tapping of threaded parts. It is an ideal choice for production needs of many industries, such as the automotive, appliance, electronics, communications, industrial, and medical industries. SR-100 features a rigid, moveable, Z-axis headstock with two 20 hp electric motors and four 2 hp spindle motors. The spindle motors can produce variable speed ranges with speeds up to 6,000 rpm for drilling, up to 10,000 rpm for tapping, and up to 50,000 rpm for finishing operations. The headstock is mounted on hardened and ground steel alloyed slides, offering extreme accuracy in movement. The machine is designed to support a wide range of tooling and fixtures as well. For production purposes, HAAS SR-100 offers the capability to accommodate quick-change drill and tapping heads, turret press adapters, and standard tools. SR-100 also includes a magazine cart system for rapid pallet changes, and an easy to use control panel. HAAS SR-100 has a generous working area of 13" X 8", providing ample workspace for a variety of applications. SR-100 also features a chuck capacity of 8" in diameter and table surface speeds in excess of 10,000 sfpm. This allows HAAS SR-100 to accommodate larger parts faster without sacrificing accuracy or quality. SR-100 is constructed from a heavy-duty C-frame structure, which is precision machined from high-grade cast iron. The frame is integrated with a four-axis servo drive system, ensuring fast, precise response and steady motion. The motor control system uses an auto-spindle, ensuring secure and precise speed and torque settings. HAAS SR-100 is easily integrated into existing production systems, its built-in spindle and automation controls make it an ideal choice for a variety of automation applications. SR-100 offers excellent accuracy, dependability, and performance. It is a leader in high-speed production drilling and tapping, offering efficient and cost-effective production for any industrial application.

There are no reviews yet