Used HULLER HILLE NBH 280 #9409087 for sale

URL successfully copied!

Tap to zoom

ID: 9409087

Vintage: 2015

CNC Machining centers

With 5-Axis linkage

3-Axis structure: Crane

5-Axis type: Cradle

Processing stroke (X, Y, Z): 500 x 460 x 340 mm

Linear axis (X, Y, Z):

Feed speed: 60 x 60 x 60 mm

Fast movement: 60 x 60 x 60 mm

SCHNEEBERGER Screw rail

Screw butterfly pitch (X, Y, Z): 20 x 20 x 20 mm

3-Axis light shed ruler (X, Y, Z)

SCHNEEBERGER Grating ruler (built-in line rail)

Z-Axis workbench distance: 110 mm

Disk size: 280 mm

FIBROPLAN AC Rotary shaft

Rotary shaft locking method: Oil pressure

HEIDENHAIN RCN 2266384 Round light

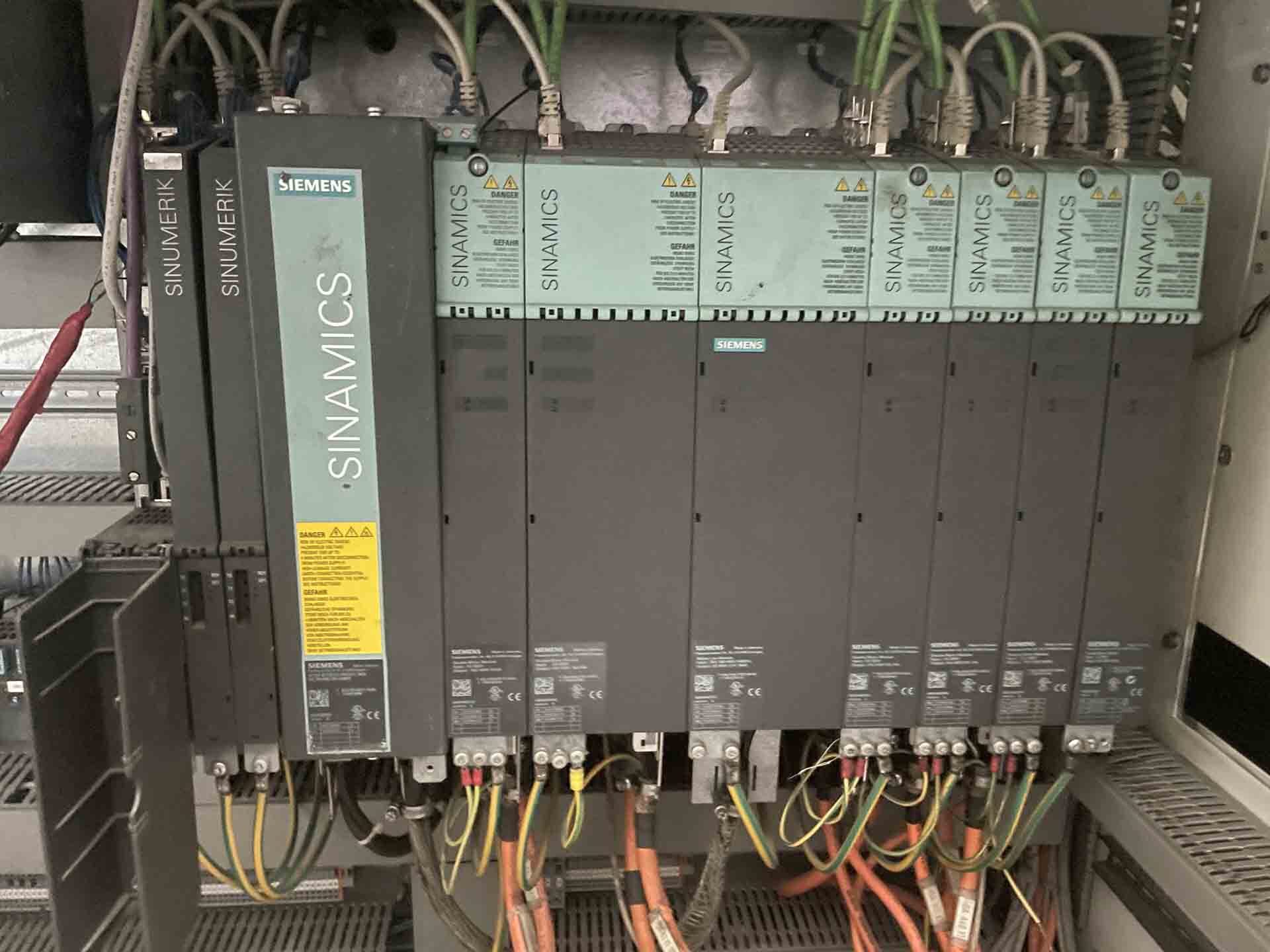

SIEMENS / WEISS Electric spindle

Speed: 24,000 RPM

Power: 7.5 kW

HSK32 Holder

Disk tool magazine: 32/60 Bit

Motor magazine driver

SIEMENS 840DS1 Controller

RTCP Function

Processing coolant

2015 vintage.

HULLER HILLE NBH 280 is a machine tool specifically designed for manufacturing complex parts with precise dimensions and shapes in a wide range of materials. This machine offers a variety of machining capabilities, making it an ideal solution for performing a wide range of operations, ranging from basic boring and turning to cutting, grinding and threading. NBH 280 is equipped with a sturdy and rigid spindle that maximizes precision and stability, even when machining on hard materials. It has a high-precision drive system, and a ball-screw drive that ensures precise and repeatable movements. The machine is also equipped with a sophisticatedly designed electronic control, providing easy operation, quick response and precise control of machining operations. HULLER HILLE NBH 280 is also fitted with a headstock and tailstock with a large range of travel. This allows for precise machining and repetitive operations, with the headstock being adjustable at 4 different positions. The X, Y and Z axes are also equipped with high-precision servo motors and can achieve precise positioning with minimal backlash, allowing for precise and precise movements. The machine also has several advanced features, such as the automatic tool changer which allows for quick tool changes without manual intervention. The machine has an arsenal of tooling to choose from, including drilling, reaming, tapping and threading tools. It also has a variety of workholding fixtures, allowing for improved clamping and accuracy while machining. NBH 280 is easily accessible and has a wide range of tool access points. This allows for multiple operations to be performed at once, making it ideal for mass production of complex parts. It is also designed with a robust and heavy-duty construction and is able to withstand harsh industrial environments. In conclusion, HULLER HILLE NBH 280 is a versatile and reliable machine tool that can efficiently and accurately produce parts of all shapes and sizes. The machine's advanced features, comprehensive tooling options and robust construction ensure it can stand up to the toughest of industrial environments. Its precise and repeatable movements make it ideal for producing high-quality components, making NBH 280 an optimal choice for producing complex parts.

There are no reviews yet