Used HYUNDAI L210A #9093553 for sale

URL successfully copied!

Tap to zoom

ID: 9093553

Vintage: 2011

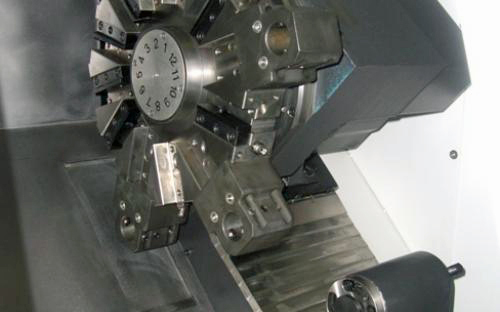

CNC Lathe

Chuck Size 8"

Max Diameter Bar Capacity 2.56"

Max Swing Over Bed / Carriage 21.7" / 13.8"

Max Turning Diameter 13.8"

Max Machining Length 16.1"

Spindle Speed 4000 RPM

Spindle Bore 3.07"

Spindle Nose A2-6

Spindle Motor 20 / 15 HP

Spindle Torque 211 ft. lbs.

Tools 12

Rapid Traverse Rates (X & Z) 1417 IPM

X-Axis Travel 8.3"

Z-Axis Travel 16.9"

Turret Index (Single Step) 0.2 Seconds

Tailstock Taper MT #4

FANUC 0i - TD Series CNC CONTROL

8.4" Color LCD

USB Port

PC / MCIA Interface

8" Samchully MH-208 Hydraulic 3-Jaw Chuck

Manual Tool Presetter

Tailstock

LNS Turbo HB Chip Conveyor (Side or Rear Exit)

Barfeed Interface

High Power Coolant

Green Indicator Light

2011 vintage.

HYUNDAI L210A is a machine tool manufactured by HYUNDAI Robotics designed with an ultra-precise cutting equipment specifically crafted for difficult to cut materials. The tool was created to meet the needs of clients that require cutting on intricate or difficult to machine materials, such as low carbon steels, stainless steel alloys, superalloys, ceramics, brass, aluminum, copper, composites, and plastics. The machine's frame is composed of a highly rigid cast iron structure designed for quiet operation and high accuracy. In order to meet the stringent requirements of those who require faster and more accurate cutting, L210A has been designed with a powerful, direct drive spindle motor capable of producing 6500 rpm. This gives the tool the capability to cut a variety of thick and thin materials with accuracy. Additionally, the machine has an automatic tool changer, allowing rapid job changes and shortened machining times. The high torque drive system maximizes the machine's cutting capacity while providing a high level of accuracy. The tool also includes an NC (numerical control) unit that enables the user to program a variety of varying processes and control cutting parameters. This machine is composed of a touch-screen input panel, a high-speed processor, and an unbeatable software-based control tool, which is user friendly and provides the user with exceptional control. The NC asset offers an array of features, such as the ability to perform common functions such as drilling, straight line cutting, contouring, and helical cutting. The environmentally friendly HYUNDAI L210A machine tool also has its own separate oil cooler and filter model to ensure that it runs cool and clean. The tool is equipped with a leveled bedplate designed to ease setup and reduce scrap rates, as well as an induction air blast equipment for the cooling of parts. The machine also includes a grease-lubed slide ways which maximize accuracy and prevent material from sticking to the slide way surface. Overall, L210A is a powerful, highly accurate machine tool designed to meet the needs of those who require ultra-precise cutting in difficult materials. With its direct drive spindle motor, NC system, and efficient cooling unit, the machine is capable of producing high quality, accurate cuts at high speeds.

There are no reviews yet