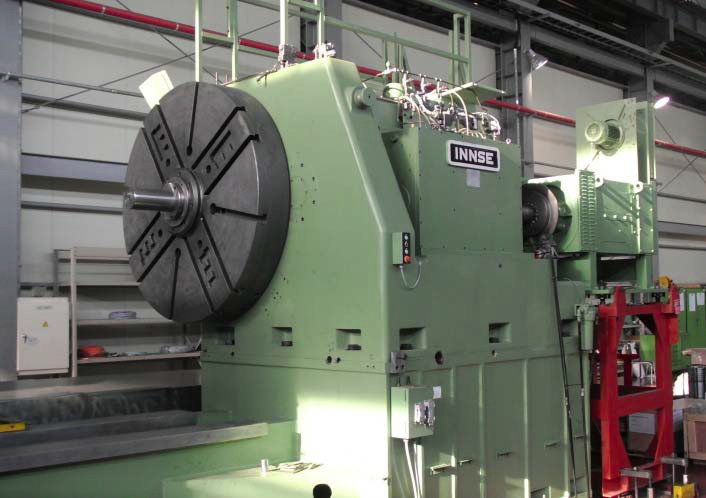

Used INNSE D2,200 x 11‐125 #9018129 for sale

URL successfully copied!

Tap to zoom

ID: 9018129

Vintage: 1983

CNC horizontal lathe

CNC: Siemens 840D PL

Traveling distance:

X-axis: 900 mm max

Y-axis: 12,000 mm max

Center height from bed: 1,500 mm

Swing over carriage: 2,200 mm

Swing over bed: 2,800 mm

Turning length: 11,000 mm

Work weight between centers: 125 ton

Main spindle drive: 176 kW

Main spindle speed: 0.8~160 rpm

Faceplate diameter: 1,750 mm

Chucking diameter: 300~1,320 mm

Headstock torque: 118 KNM

Cutting force: 200 KNM

Z-axis feed rate: Max. 6,000 mm/min

X-axis feed rate: Max. 2,500 mm/min

Number of tool holders: 3 pcs (Headstock side 95 mm, Tailstock side 60 mm, 45 mm)

Bed width: 2,800 mm

Bed way: 4 ways

Steady rest (metal type): 2 sets

1983 vintage.

INNSE D2,200 x 11‐125 is a specialized machine tool designed to provide precision machining of components for industrial use. It is a multifunctional vertical boring and milling machine capable of taking on an array of complex milling, boring, drilling, tapping, and reaming jobs, and it is equipped with an array of powerful CNC control features. This tool can process components made of a wide range of materials, including aluminum, brass, steel, and composites. The D2,200 x 11‐125 is designed to be precisely and symmetrically positioned upon a base platform with adjustable feet for excellent job accuracy, and it is controlled by a powerful single-step CNC system. All movements are CNC-driven, with the user able to program multiple tables or steps into each working cycle to precision-cut each component to its exact dimensions and specifications. It also features automatic static compensation (ASCC) programming that compensates for any slightvariances in the spacing of the cutting edges, helping to ensure accuracy and precision operations. The machine's robust design enables it to handle maximum feed rates of up to 16,500 mm/min, and its feed system is equipped with a PID controller and rapid traverse acceleration, optimizing the production speed of shorter jobs and quicker cycle times. It also offers a consistent coolant flow rate throughout the milling cycle, with each operation cooled using a special lubricant that helps to prevent material buildup on cutting surfaces and helps extend the overall life of the cutting tool. The D2,200 x 11‐125 is powered by an 11.8 kW spindle motor that delivers fast output torque and low-speed operation, allowing for heavy-duty cutting capabilities. The spindle speed range is adjustable between 31.2 to 2500 rpm, and the machine also offers an impressive range of tool holders and a full range of cutting tools. In sum, INNSE D2,200 x 11‐125 is a powerful and reliable machine tool designed to provide effective high-precision cutting and milling capabilities, as well as a full range of operations. Its advanced CNC programming features and ability to handle a variety of complex machining operations make it an ideal choice for a wide range of industrial applications.

There are no reviews yet