Used JOHNFORD TC-75 #9093558 for sale

URL successfully copied!

Tap to zoom

ID: 9093558

Vintage: 1996

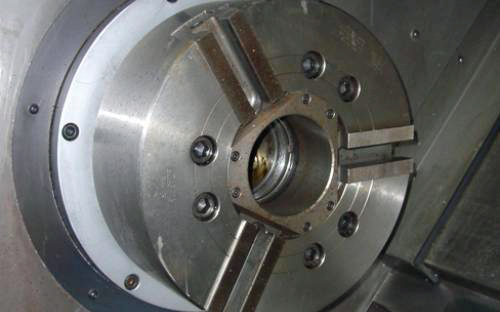

CNC Lathe

Chuck Size 15"

Max Diameter Bar Capacity 4.13"

Max Swing Over Bed / Carriage 27.17" / 18.5"

Max Turning Diameter 21.25"

Distance Between Centers 67.32"

Tools 12

Spindle Speed 20 - 1700 RPM

Spindle Bore 4.84"

Spindle Nose A2-11

Spindle Motor 35 / 30 HP

Spindle Torque 5396 Ft. Lbs.

Rapid Traverse Rates (X / Z) 315 / 400 IPM

X-Axis Travel 13.78"

Z-Axis Travel 61.02"

Tailstock Taper MT #5

FANUC 0T CNC CONTROL

9" Monochrome CRT

15" Kitagawa B15 Hydraulic 3-Jaw Chuck

Programmable Tailstock Body & Quill

Manual Steady Rest (6" Dia. Capacity)

Chip Conveyor (Side Exit)

Portable Pendant CNC Control

Yellow Operation End Light

4-Gear Range Headstock

Slant Bed Box Way Construction

1996 vintage.

JOHNFORD TC-75 is a premier CNC vertical machining center designed for precision, productivity, and efficiency. This four axis machine tool is versatile and powerful, making it the ideal choice for manufacturing high-precision parts and intricate components. TC-75 features a precision spindle drive capable of generating 850 PSI, allowing for rapid and exacting operations. Its advanced design is capable of cutting extremely tough materials, including stainless steel and titanium. This highly accurate machine utilizes dual contact lines, giving it a higher accuracy rate than the single line contact designs. JOHNFORD TC-75 has an impressive mean-time-between-failures rating of up to 200,000 cutting hours. This durable tool is equipped with a two-year parts and labor warranty to give peace of mind to its owners. To increase productivity, the machine is capable of cutting at two different speeds using two different tools. This feature reduces machine set up time and increases accuracy. TC-75 combines advanced and robust components with a precision construction to provide its users with excellent features and benefits. This solid machine tool has a robust casting bed with a maximum machining table of 82.67 x 55.12 inches, and a Z-axis travel of 24.4 inches. The device also includes a programmable coolant nozzle and an oil mist lubrication system. This machine tool comes with a Heidenhain iTNC 530 wired interface which helps operators to monitor and control ongoing processes, as well as set, store, and recall machining programs. With its touchscreen user interface, the machine can be operated intuitively, without the need for complex language commands. JOHNFORD TC-75 is a powerful and efficient tool designed to make high-precision machining and part production easy. With its advantages in ease-of-use, powerful cutting capabilities, and robust construction, it has become a go-to choice for many businesses in the manufacturing industry.

There are no reviews yet