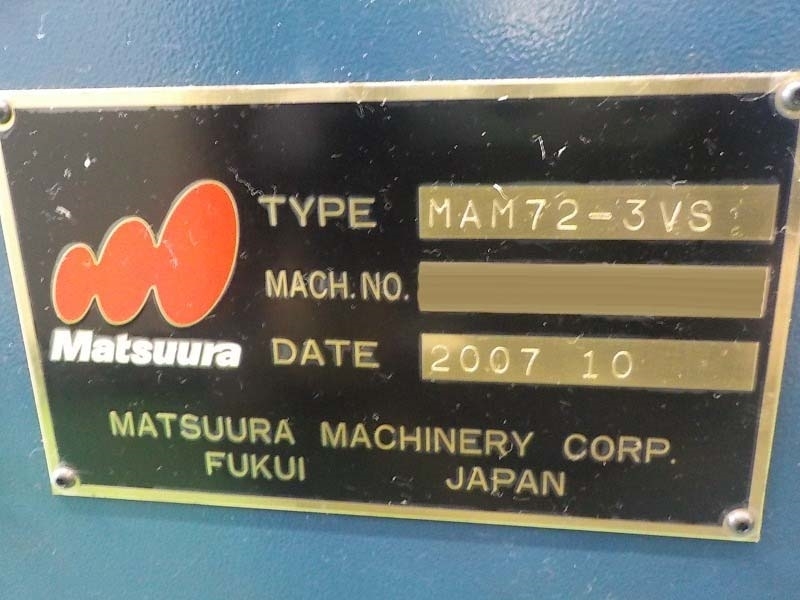

Used MATSUURA MAM72-3VS #9284476 for sale

URL successfully copied!

Tap to zoom

ID: 9284476

Vintage: 2007

CNC Vertical machine center

Control: G-Tech 30i

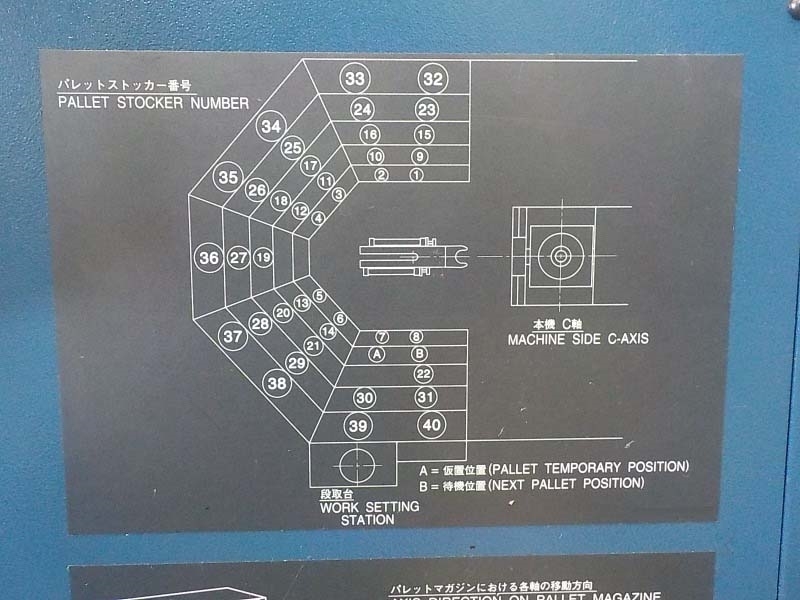

Table size: 130 mm (40 APC)

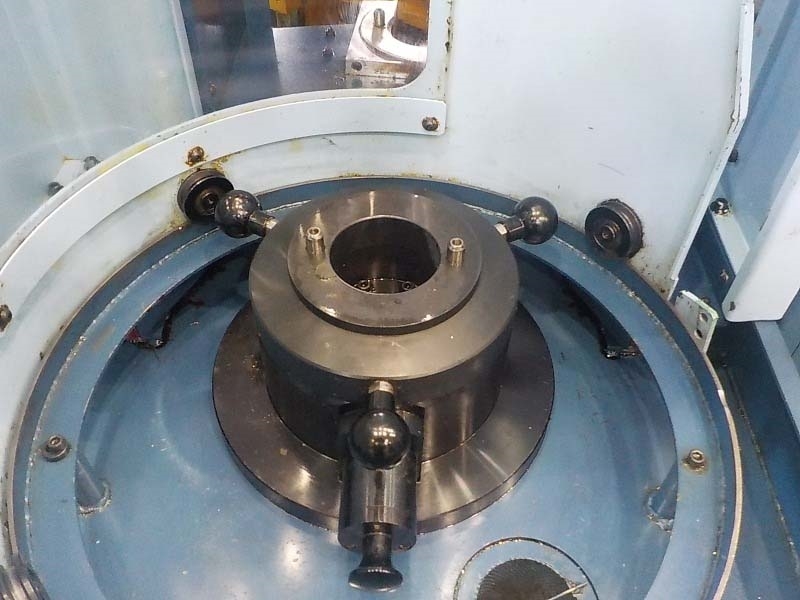

Working size (Maximum): 300 (Diameter) x 250 (Height)

Maximum loading weight: 60 kg

Stroke (X, Y, Z): 680 mm x 400 mm x 625 mm

B-Axis: +65° / -110°

C-Axis: 360°

Table indexing: 0.001°

Spindle speed: 15,000 rpm

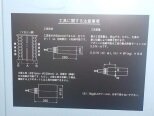

BT40

ATC: 90

Scale feedback (B/C)

HEIDENHAIN Scale (X, Y, Z)

Cutting oil oilcon (200 L tank)

Left front lift-up conveyor

In-flight chip controller

5-axis package

2007 vintage.

MATSUURA MAM72-3VS is a highly efficient and reliable three-axis vertical machining center from MATSUURA Machinery, a Japanese manufacturer well-known for producing reliable and powerful machine tools. It is commonly used in a range of industries including automotive, aerospace and electronic production. MAM72-3VS is a single-column, solid cast iron machine that offers powerful reliable machining in a compact, space-saving design. The machine is equipped with a 15 hp spindle motor and a high-accuracy direct-drive spindle technology that delivers speeds of up to 12,000 RPM with highly precise positioning. It also features a 24" x 16" worktable with a 721 lb. capacity, and a 40-pocket tool changer for automatic tool exchange. Additionally, MATSUURA MAM72-3VS is equipped with a thermal displacement compensation system that helps to maintain precise machining over coupled axis movements and varying temperatures. MAM72-3VS is designed with a wide variety of features to help ensure optimal performance and accuracy. It is equipped with dual contact linear guided ways for high speed, repeatable, and accurate positioning. The machine also features a base with heavy ribbing to reduce vibrations and ensure greater accuracy, as well as hand-scraped linear bearings to minimize friction and extend its accuracy over longer machining periods. Additionally, the machine has a highly rigid power head and an integrated in-line spindle motor that increases torque and reduces vibration for even greater accuracy. MATSUURA MAM72-3VS is ideal for achieving tight tolerances on a wide variety of materials. It is capable of producing complex parts with high precision in a short amount of time, making it an efficient and cost-effective machine for any production environment. It is also equipped with a variety of safety features including a dual hand safety-pultrusion control system and emergency stop buttons to protect operators and ensure safe operation. Overall, MAM72-3VS is a reliable and powerful three-axis machining center ideal for any production environment. Its highly efficient and accurate production capabilities make it an excellent choice for machining a wide variety of materials quickly and precisely. Its robust construction and wide-ranging safety features make it a reliable choice that produces parts with highly accurate results.

There are no reviews yet