Used MATSUURA MC-1000V5 #9083457 for sale

URL successfully copied!

Tap to zoom

ID: 9083457

Vintage: 1983

Vertical Machining Center

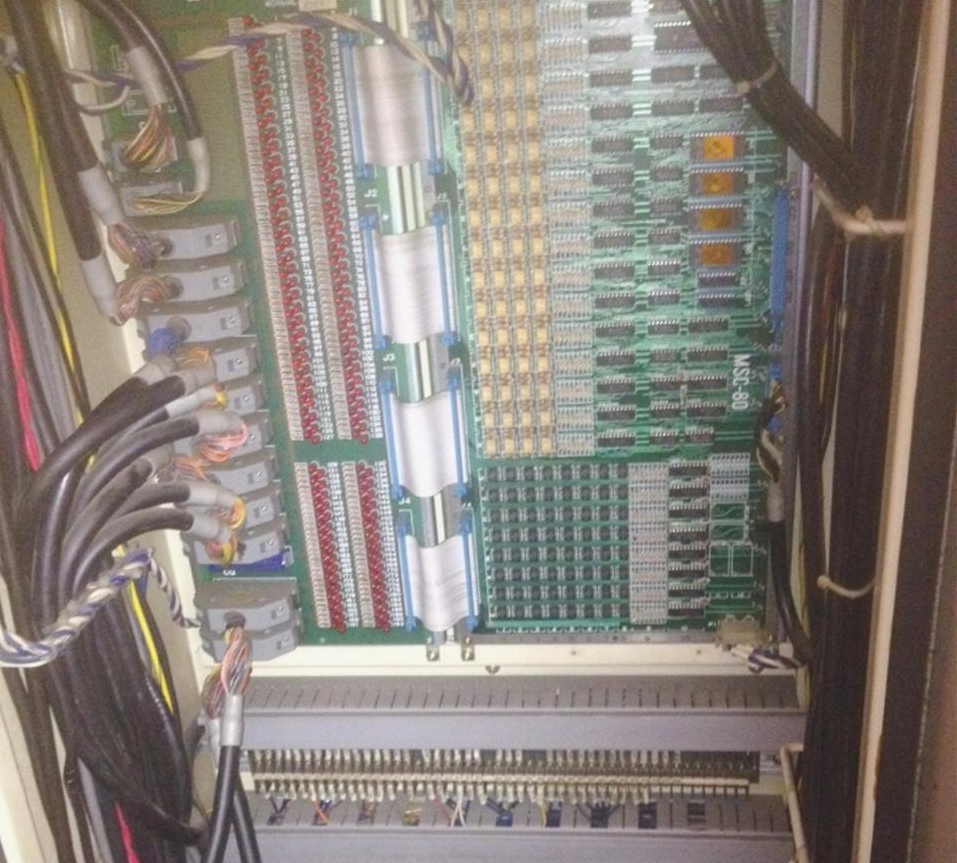

Fanuc 6MB

Specifications

Table Size : 55.1" x 19.7"

Table Load Capacity: 2,200 lbs.

X-Axis Travel: 41.3"

Y-Axis Travel: 20"

Z-Axis Travel: 22"

Spindle Taper: BT # 45

Spindle Motor: 20 HP

Spindle Speed: 20 - 3,580 RPM

Tool Magazine Capacity: 35 Position ATC

Max. Tool Diam./Length/Weight: 5.91"/15.7"/33 lbs.

Rapid Traverse Rates: X, Y / Z 472 IPM / 394 IPM

Machine Dimensions : 62" x 138" x 122"

Machine Weight: 16,100 lbs.

Equiped with:

Heavy Duty Boxed Ways

35 Position Side Mounted Tool Changer

All Available Manuals

Coolant System

RS-232 Port for DNC Interface

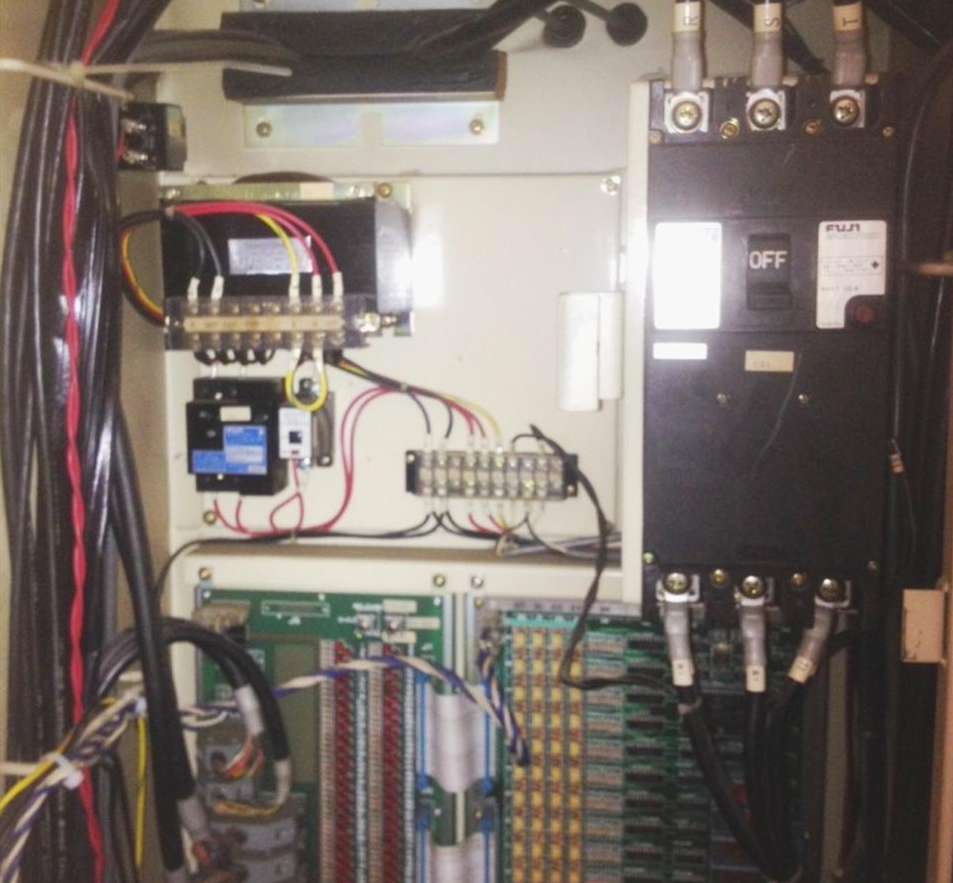

Toolchanger currently not functioning due to a electronic issue, otherwise machine runs fine

Tooling Package w/ Approx. (100) Tool holders

1983 vintage.

MATSUURA MC-1000V5 is an advanced 5-axis CNC machining center designed to provide exceptional performance and reliability for the most demanding machining requirements. It is equipped with a range of cutting-edge automated features, built on a large cast iron base, to provide a solid foundation for production-quality parts. The machine offers a spindle speed of up to 12,000 RPM, a high-speed direct drive, a geared head, and a spindle torque of up to 715 Nm. This combination creates a powerful cutting force allowing for the manufacture of intricate parts and components with fast cycle times. The machine features an innovative, intuitive machine control equipment and a full manual mode to provide operators with easy-to-use control of all the machine functions. The advanced control system is designed to automate operations and provide smooth, high-precision machining operations using the smallest amounts of positive and negative tolerance range with minimal programming effort. MC-1000V5 is also equipped with an automatic tool changer to perform up to 70 simultaneous tool changes. This greatly reduces setup time and improves productivity and production quality. The machine also features the latest probing and vision systems as well as dynamic measurements to ensure accurate part positioning. MATSUURA MC-1000V5 is designed with an open-architecture design to provide compatibility with all of today's CAD/CAM software and CNC controllers. The integrated meshing technology is a user-friendly method that automatically provides 3-D contouring based on the previously programmed machining data and allows for easy customization according to the machining requirements. The machine is also design in such a way to provide the metal-working industry with optimal accuracy, speed, and stability. The utilization of cutting-edge servo technology allows for enhanced dynamic performance allowing it to offer higher machining accuracy and repeatability. For added convenience, MC-1000V5 is equipped with a range of features such as automatic lubrication, an automatic coolant supply unit, and an integrated cooling machine. The machine also has a variety of options to further enhance its performance such as high-pressure mist coolant, spindle coolant, and a 40-position automated tool changer. In conclusion, MATSUURA MC-1000V5 5-axis CNC Machining Center is engineered to provide enhanced operations and productivity for a range of metal-working needs. It features advanced technology, a powerful spindle, and an intuitive CNC control tool to provide the ultimate in precision and quality for the production of intricate components.

There are no reviews yet