Used MITSUI SEIKI H6C #9113786 for sale

URL successfully copied!

Tap to zoom

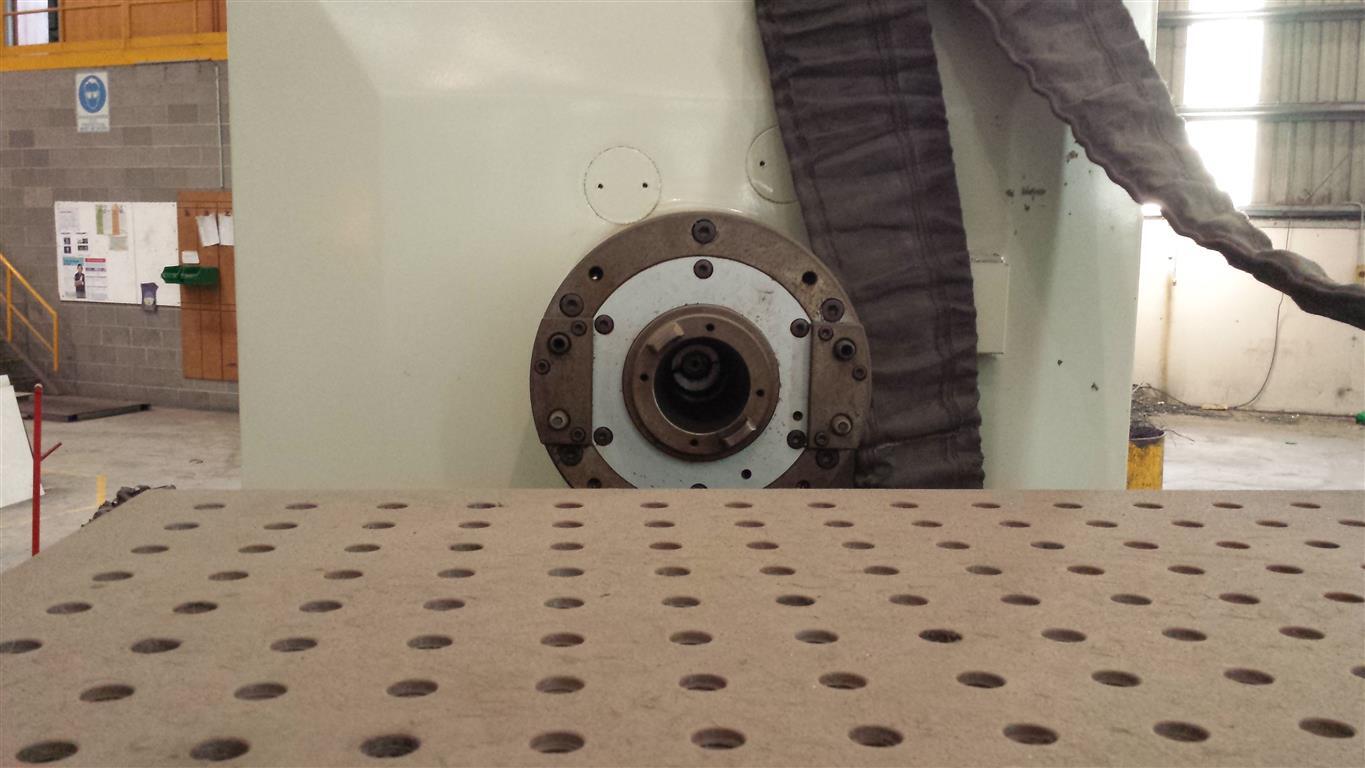

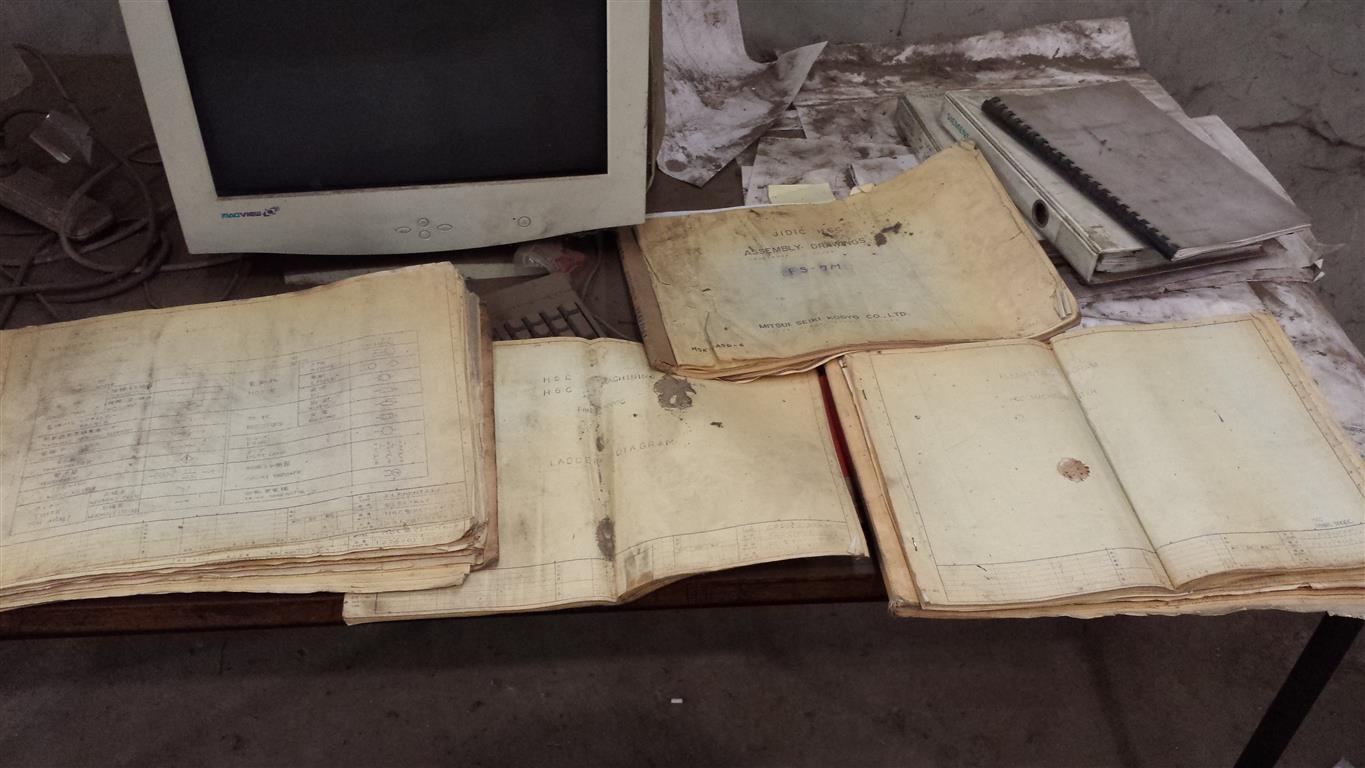

MITSUI SEIKI H6C is a five-axis horizontal machining center manufactured and distributed by the Japanese company MITSUI SEIKI. This machine is designed for the production of parts requiring high precision, superior surface finish, and complex shapes. H6C's orthogonal column structure ensures rigidity and stability, and contributes to accurate and delicate machining. The machine allows for up to six simultaneous axes of motion simultaneously, and a maximum spindle speed of 14,000 RPM. The machine's rapid feedrate of 27.5 m/min makes it suitable for high-speed machining applications. It also has a maximum table load of 1380 kg, giving it a high degree of versatility. Furthermore, MITSUI SEIKI H6C series is equipped with a Fanuc series 33i-C CNC, offering comprehensive isometric drawing production and a user-friendly interface. The CNC can also be facilitated with options such as conversational programming, hole-making, and curve offsetting. H6C machine utilizes a hiwin hydrostatic spindle bearing equipment and a 10,000 rpm spindle motor to reach the highest accuracy and surface quality. This spindle system eliminates cutting force variations, resulting in excellent surface finish and preserving tool life. Additionally, MITSUI SEIKI H6C has an IK05 enclosure that prevents cutting chips and other debris from entering the inner components of the machine. The enclosure also contains a built-in mist collector that cools the workpieces and machine in order to reduce the heat generation during operation. H6C also features a range of tools and fixtures, from cutting tools to workholding fixtures, that make it suitable for a variety of machining processes. This machine is capable of performing operations such as drilling, boring, tapping, reaming, and counter-boring. It can also produce threads from M5 to M50 and T-slots of up to 60 mm in width. MITSUI SEIKI H6C has an advanced lubrication unit for its tools and spindles, controlling the supply of oil to ensure a consistent and efficient performance. Overall, H6C is an advanced horizontal machining center that is designed for the production of complex parts with the highest accuracy and surface finish. This machine includes a range of features such as rapid feedrates, a Fanuc CNC, a hiwin hydrostatic spindle bearing machine, and an IK05 enclosure. The vast range of tools and fixtures makes it ideal for a variety of machining applications.

There are no reviews yet