Used OKK HM-4 #197851 for sale

URL successfully copied!

Tap to zoom

ID: 197851

Vintage: 2002

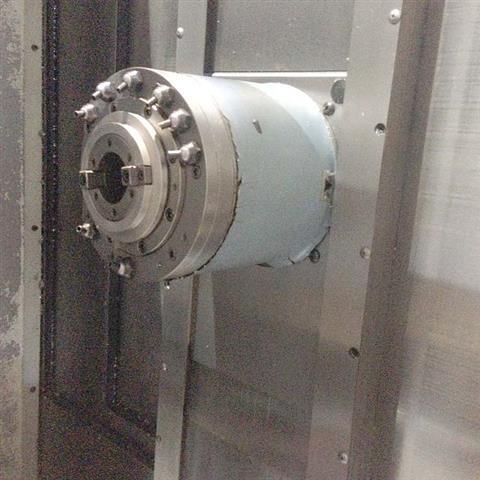

Horizontal Machining Center

Fanuc 21i CNC

14" Color CRT

(2) 15.7" x 15.7" Pallets

1°Indexing pallet rotation

40-Position automatic tool changer

RS-232 Port

Full coolant enclosure

Automatic hydraulic

Part clamping system

Chip conveyor

High pressure thru spindle

Coolant system

Specifications:

Longitudinal travel (x-axis): 22"

Vertical travel (y-axis): 20"

Spindle travel (z-axis): 22"

Pallet dimensions: 15.7"x 15.7"

Maximum pallet load: 3000 lbs

Number of pallets: 2

Number of index positions: 360

Feed rate, all axes: .04-1575 ipm

Rapid traverse, all axes: 1575 ipm

Spindle horsepower: 30 hp

Spindle speed range: 30-10,000 rpm

Spindle taper: #40 cat

Number of tool stations: 40

Electrics: 220/3/60

2002 vintage.

OKK HM-4 is a heavy-duty vertical machining center that is designed to produce precision parts with consistent product accuracy and repeatability. This milling machine comes with a highly efficient spindle with a maximum spindle horsepower of 15HP, and the spindle speed range is up to 12,000 RPM. The tooling configuration of the machine tool ensures smooth and reliable cutting. The cutting accuracy is maintained by using the standard direct-drive design. This is a CNC machine tool with a traveling column design, and includes three axes, X, Y, and Z. The solid square box bed has a base area of 4,300 mm x 2,500 mm with a maximum height of 1,050 mm, and maximum weight capacity of 4,500 Kgs. The Z-axis travel is a standard 900mm, with options up to 1,500 mm. The table has a size of 2,500 mm x 1,300 mm with a maximum loading capacity of 1,500 Kgs. The ATC has a tool capacity of up to 20 tools and 20 pallet locations. For greater productivity, the machine can be operated in conjunction with the optional Automatic Pallet Changer. HM-4 has an enhanced user-friendly CNC control with a 15" Color LCD Touch Panel, made in Japan. The control is equipped with advanced processing functions such as skip function, circle-function, mirror image, and multi-axis machining. This facilitates efficient operations, resulting in improved productivity. Furthermore, the machine comes with the WinLink NC, which is a standard feature that provides networking capabilities with the machine controller. The machine features a large-capacity flood coolant system and a chip conveyor for easier disposal of chips. Moreover, the machine also has a unique oil mist collectors to collect oil mist that is generated when drilling or milling. The machine also has a peripheral extractor system, which is optional and allows efficient collection of chips and cooling lubricant from the machining environment. OKK HM-4 is designed for customers looking for improved productivity, consistent product accuracy, and reliable cutting performance. It is a machine that can handle large-scale, complex machining operations with its powerful spindle, high accuracy, and wide range of cutting options. The machine is well suited for the automotive, aerospace, and medical industry.

There are no reviews yet