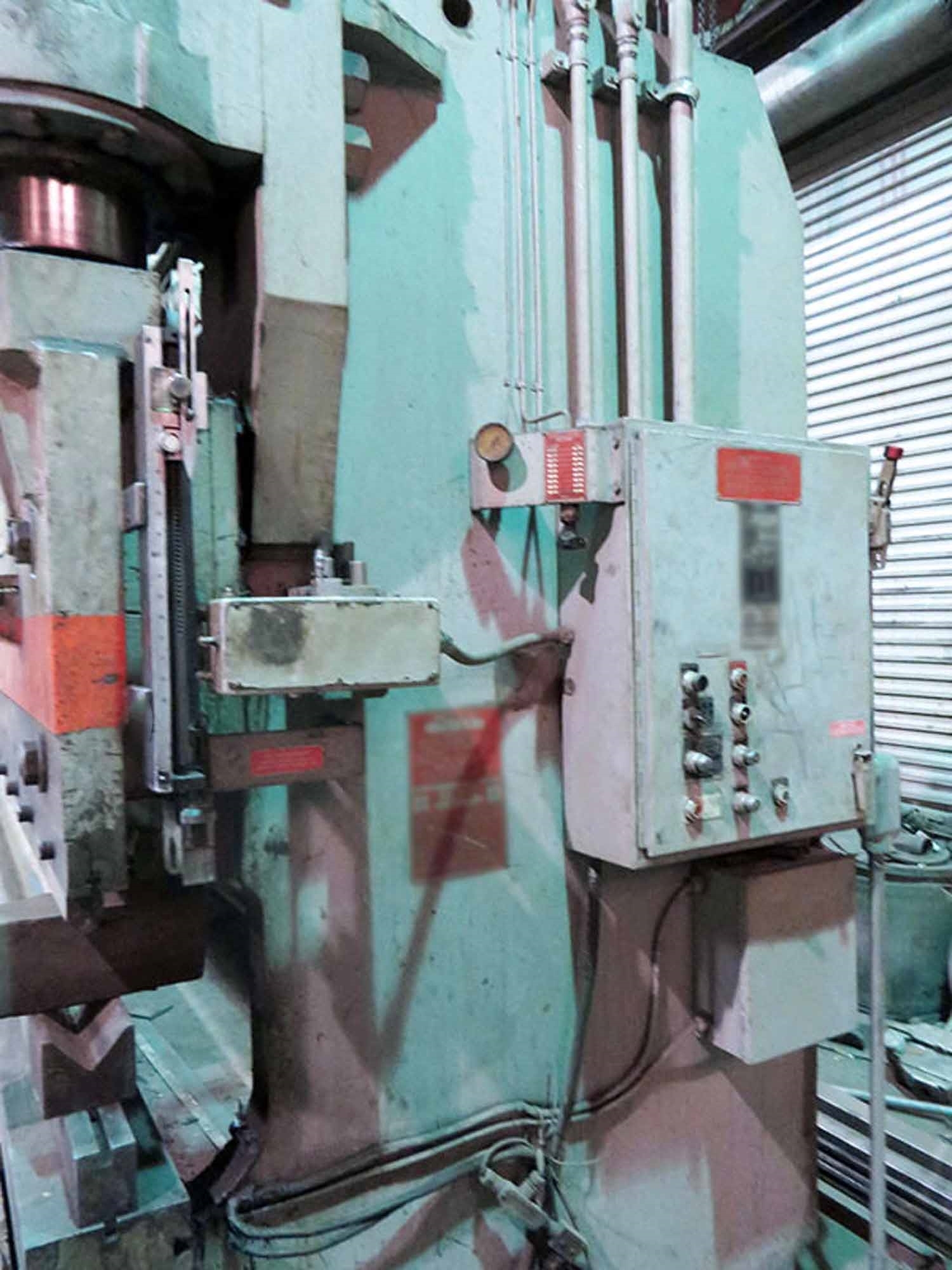

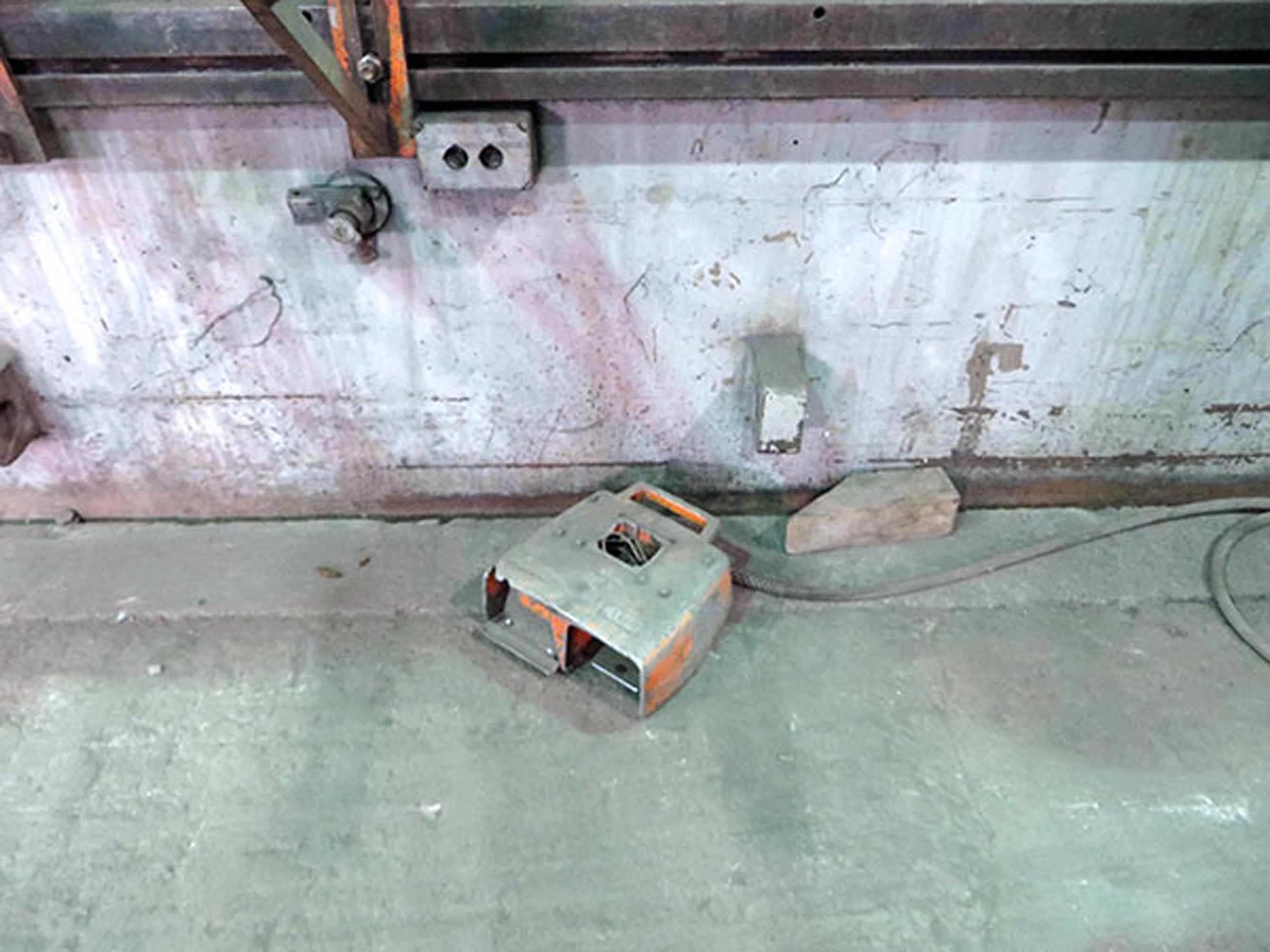

Used PACIFIC K350-18 #9212757 for sale

URL successfully copied!

Tap to zoom

ID: 9212757

Vintage: 1978

Press brake

Stroke: 12"

Open height: 20"

Throat: 10"

Distance between housings: 16' 5"

Cycle top height above floor: 118"

Platen height above floor: 32"

Bed protection below floor: 49"

Maximum ram height above cylinder: 15"

Stroke of ram: 12"

Closed height: 8"

Throat height: 15"

Throat depth: 10"

Platen width: 8"

Spindle motor (HP): 30 HP

Rapid speed: 56 IPM

Normal speed: 27 IPM

Return speed: 58 IPM

Options / Equipped with assorted dies

1978 vintage.

PACIFIC K350-18 is a heavy-duty CNC boring and machining center designed for the most exacting and demanding of industrial applications. It offers a high performance solution for those who require precise and accurate machining. K350-18 machine tool is a two piece machining center consisting of a heavy-duty base and an overhead gantry. The overhead gantry is equipped with an 18-tool ATC (Automatic Tool Changer) which allows for quick and easy tool changes during the machining process. This ATC also reduces tool change times which increases the machine's production efficiency. The machine is fitted with three drives for its operation; two rectified AC digital servo motors power the X and Y axes and a DC torque motor powers the Z axis. All axes are driven with low backlash and feature a high level of accuracy and repeatability. The bed of PACIFIC K350-18 is built from high strength cast iron, precision machined and clamped together to make a machine of the highest precision. This rigid construction reduces vibration, assuring accurate long-term machining results. A Fanuc 30iB CNC controller is used to control the machine with a 15" touch screen for easy operation and programming. The controller has an open architecture allowing it to be interfaced with many different software programs making K350-18 a very flexible machine. In addition to its robust construction, PACIFIC K350-18 also offers superior thermal stability. High-power electric spindle motors are used to drive the tool head, providing ample torque and speed to get the job done. The spindle is cooled using a forced air-cooling system, ensuring accurate and stable machining. K350-18 can used to machine a wide range of materials, including steel, aluminum, titanium, and plastics. The machine has the capacity to perform a number of operations ranging from drilling to milling, reaming, tapping, facing, and grooving. PACIFIC K350-18 is a serious piece of equipment for those looking for flexibility, accuracy, and reliability in a heavy-duty machining center. It is well suited for many machining jobs and can handle the most exacting demands and most rigorous applications. With its superior build quality and thermal stability and its ability to handle a multitude of materials and operations, K350-18 is sure to be a valuable asset for any industrial company.

There are no reviews yet