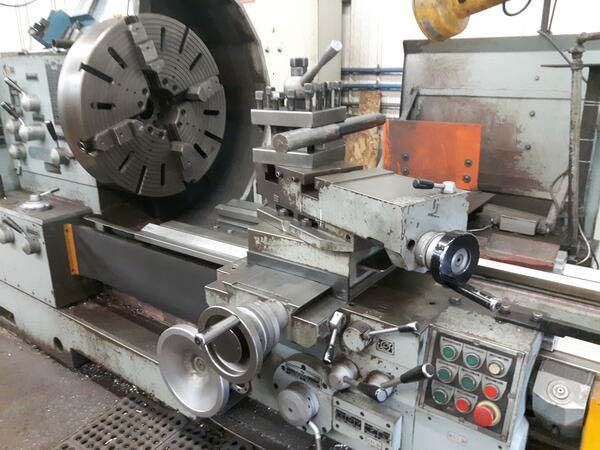

Used POREBA TPK-90A1-3M #9396884 for sale

URL successfully copied!

Tap to zoom

ID: 9396884

Vintage: 2000

Manual engine lathe

Swing over bed: 36 1/2" (927 mm)

Swing over cross slide: 25"

Swing in GAP: 49"

Length of GAP: 17"

Distance between center: 120" (3048 mm)

Spindle bore: 3 3/4"

Spindle nose: A1-11

Spindle motor: 20/30 HP

Spindle speeds (2 Ranges): 7.1-710 RPM

(122) Feeds-Long: 0043-5 IPM

(122) Cross: 0021-25 IPM

Top slide: 001-125 IPM

Threading: 1/4-30" TPI

Metric: 1-120 MM/REV

Cross slide travel: 18 1/2"

Top slide travel: 11 3/4"

Rapid traverse - Long / Cross: 260/130 IPM

Top slide: 65 IPM

Tailstock:

Drilling diameter: 5 1/8"

Drilling length: 40"

Taper: MT 6

Travel: 11 3/4"

2000 vintage.

POREBA TPK-90A1-3M is a universal heavy-duty machine tool designed for precision machining of medium and large workpieces. It is equipped with a set of modular and specialized components to make a wide variety of operations and give excellent accuracy. TPK-90A1-3M features a heavily ribbed, stable, and thermally symmetrical cast iron base, providing for maximum rigidity and thermal stability. The machine is equipped with an infinitely variable disk type wheel head drive, allowing for smooth and exact adjustment of cutting speed with full protection against overload. The wheel head is driven by two high-torque AC motors, with up to 3000rpm. POREBA TPK-90A1-3M travel ranges in X, Y, and Z axes are 900x900x1000mm (35.4"x35.4"x39.4"). It is equipped with precision hardened and scraped precision ground slides and precision ground ball screws for high accuracy and smooth operation. The spindle is driven by a powerful AC motor and has a maximum speed of 3000 rpm, and a maximum spindle power of 22kW. It includes a high-precision grinding spindle and is capable of grinding on the Ø500mm (19.7") table with a maximum static load of 10000kN. TPK-90A1-3M is equipped with a 12 position turret, with manual rapid advance capabilities, for extremely fast and precise cutting cycles. It is capable of working with various tooling, including faced cutters, face milling cutters, drill bits, and taps as well as grinding wheels. The machine is controlled by a CNC system, allowing for precise machining of intricate parts as well as ready-to-use graphic programs, multi-axis synchronization, and user-defined macros. The inbuilt control software enables easy programming and offers a wide range of features for development of complex machining programs. POREBA TPK-90A1-3M is renowned for its robustness and reliability, coupled with superior cutting performance. This machine provides excellent levels of accuracy, with +/- 0.005mm (0.0002") repeatability and +/- 0.008mm (0.0003") positioning accuracy. Its high rigidity and thermal stability make it an ideal choice for heavy-duty applications, such as grinding and milling operations. In summary, TPK-90A1-3M is a versatile and highly accurate machine tool that is suitable for a wide range of machining operations. With a high power spindle, strong base, and precise CNC control, POREBA TPK-90A1-3M ensures maximum machining performance, repeatability, and accuracy.

There are no reviews yet