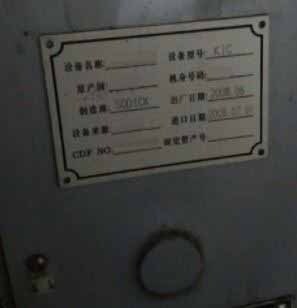

Used SODICK KIC #9168870 for sale

URL successfully copied!

Tap to zoom

SODICK KIC machine tool is considered to be one of the world's leading state-of-the-art CNC machining centers. The design of KIC is based on a high rigidity cast-iron base integrated with a full-size linear motor table. This ensures maximum accuracy, speed, and repeatability, allowing users to quickly produce precision parts. SODICK KIC is a 5-axis CNC machining center featuring a large-stroke, powerful 25HP spindle and high-accuracy linear motors. Its rigid twin-column design also provides enhanced accuracy and prevents deflection due to cutting force. Additionally, it has an intelligent mirror-image option for symmetric milling operations. With its powerful and fast spindle, KIC can handle a wide range of materials. SODICK KIC's spindle is designed to provide maximum precision and high speed cutting, making it suitable for a wide range of applications. Its high torque spindle prevents vibration and allows for more accurate cutting, so it can handle hard, tough materials as well as precise materials. The spindle can also be programmed to move in both horizontal and vertical planes to achieve greater precision. It also features a full-function hand-held pendant for easy machine control. KIC also has an intelligent use of casting materials in its base. This helps to dampen noise, vibration, and thermal deformation and ensures that SODICK KIC runs smoothly and accurately. Additionally, the powder-coated base helps protect the machine from rust and damage, so it lasts for many years. Advanced 5-axis machining controls and advanced CNC software programs offered by KIC, make it a versatile tool. It not only provides maximum speed and accuracy, but can also handle complex machining operations. It's also easy to learn how to operate, shortening the learning curve for an operator. Overall, SODICK KIC is one of the leading CNC machining centers in the world, providing high accuracy, speed, and repeatability. Its rigid twin-column design ensures maximum stability, while its intelligent use of casting materials decreases both noise and thermal deformation. Its powerful spindle enables it to handle a range of materials and applications, while its high torque spindle allows for increased accuracy and reduced vibration. Finally, advanced 5-axis machining controls and an intuitive user interface make it a great choice for both experienced and novice operators.

There are no reviews yet