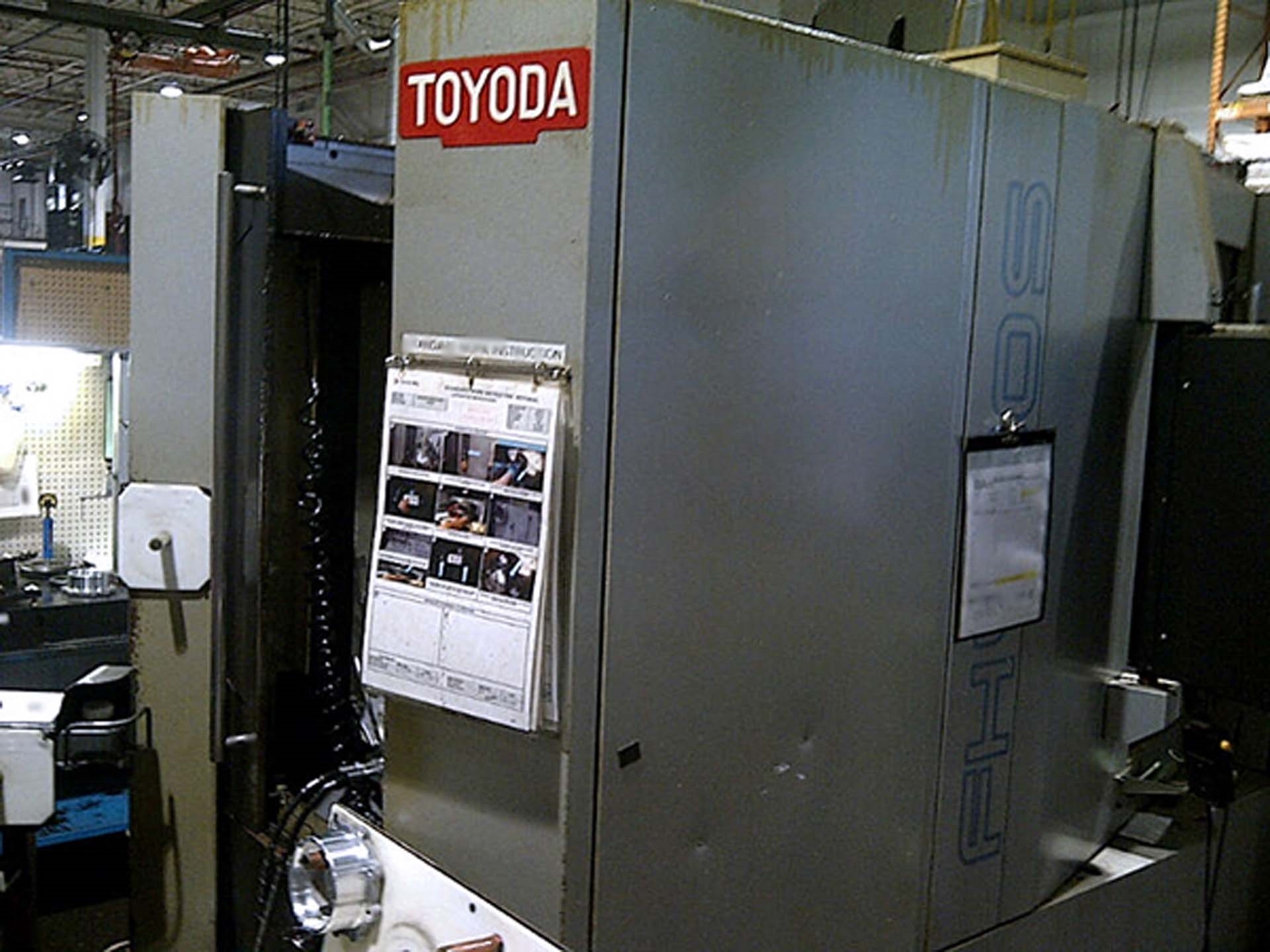

Used TOYODA FH-450S #9262371 for sale

URL successfully copied!

Tap to zoom

ID: 9262371

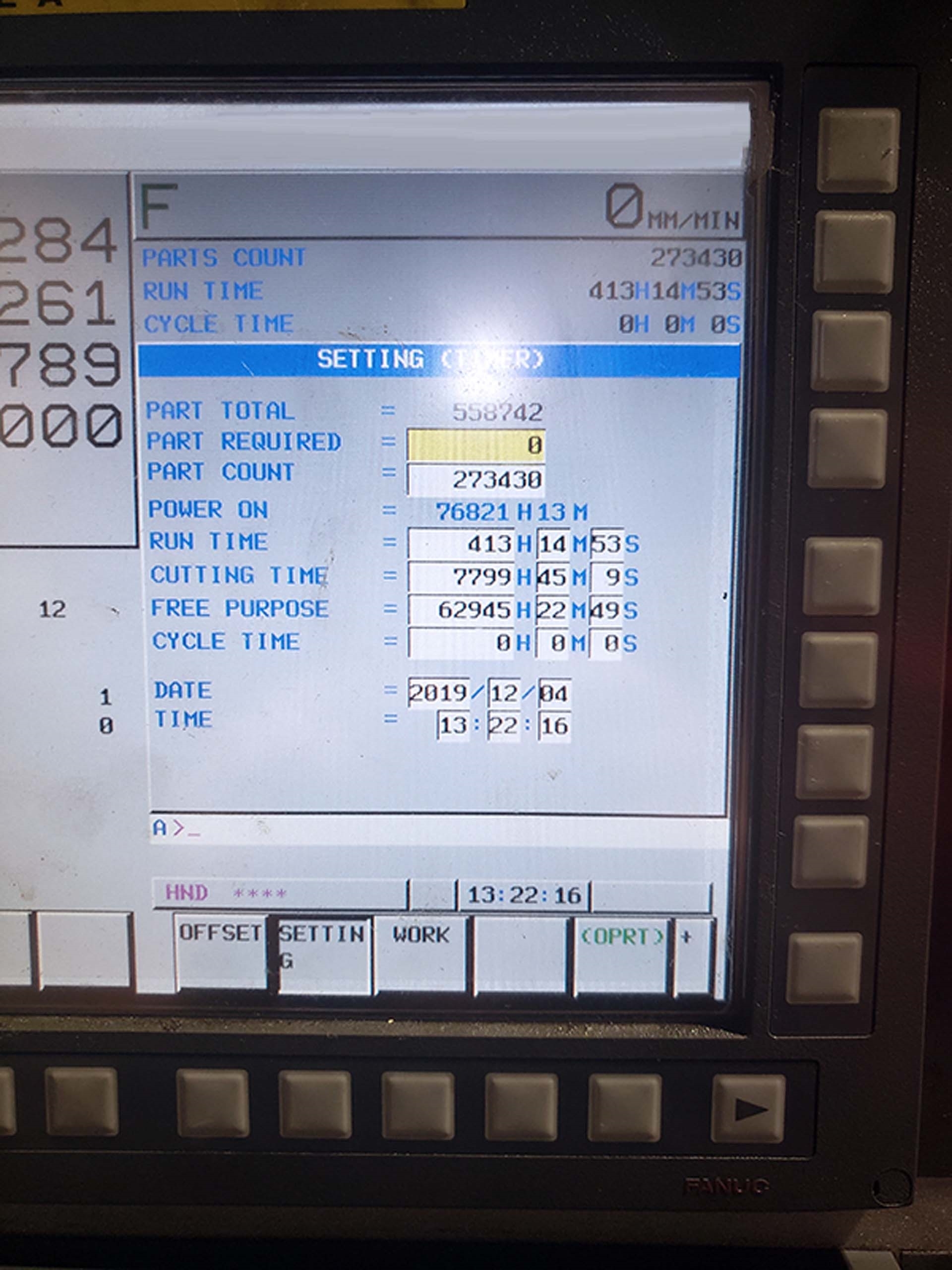

Vintage: 2008

Horizontal machine center

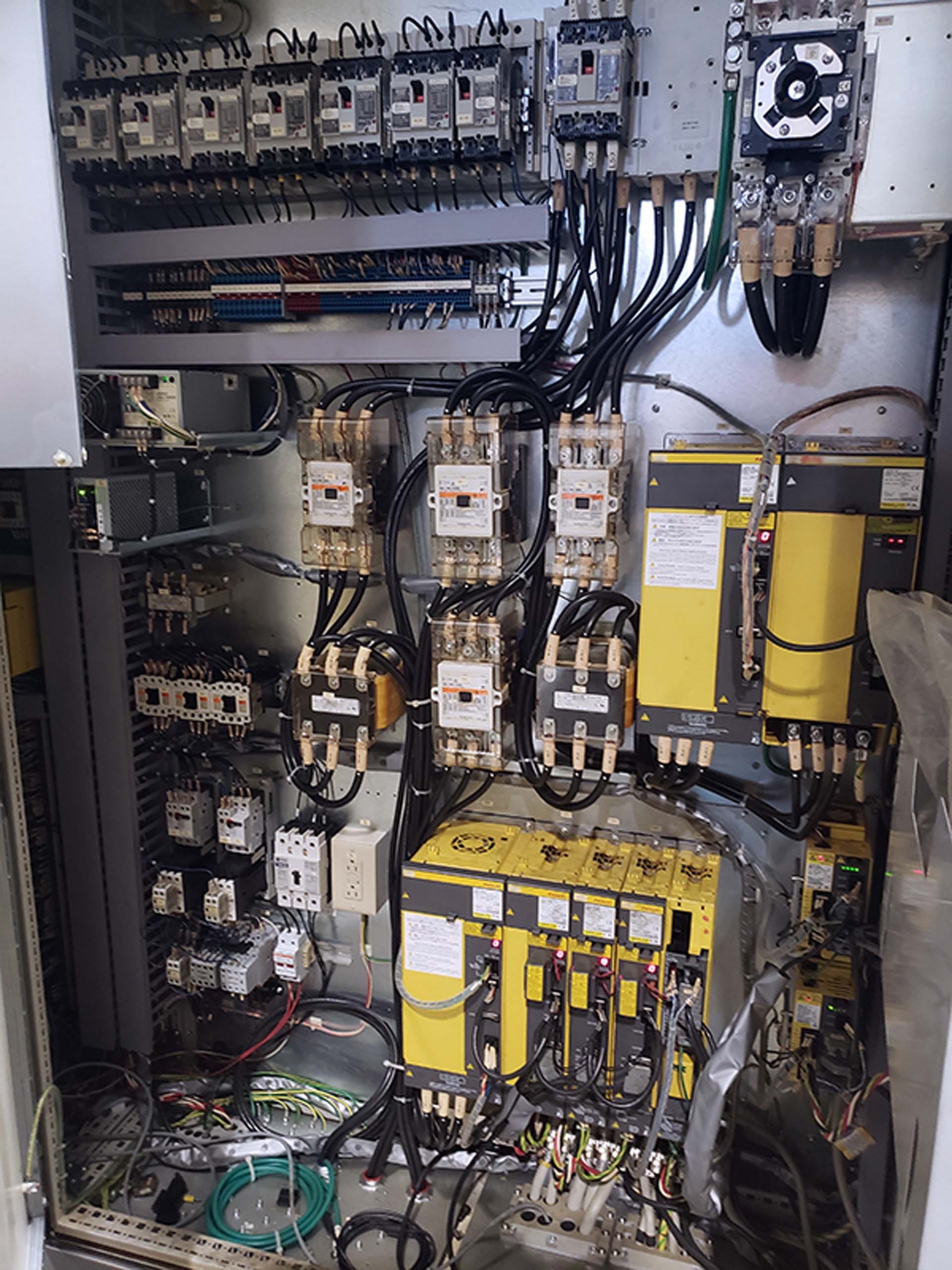

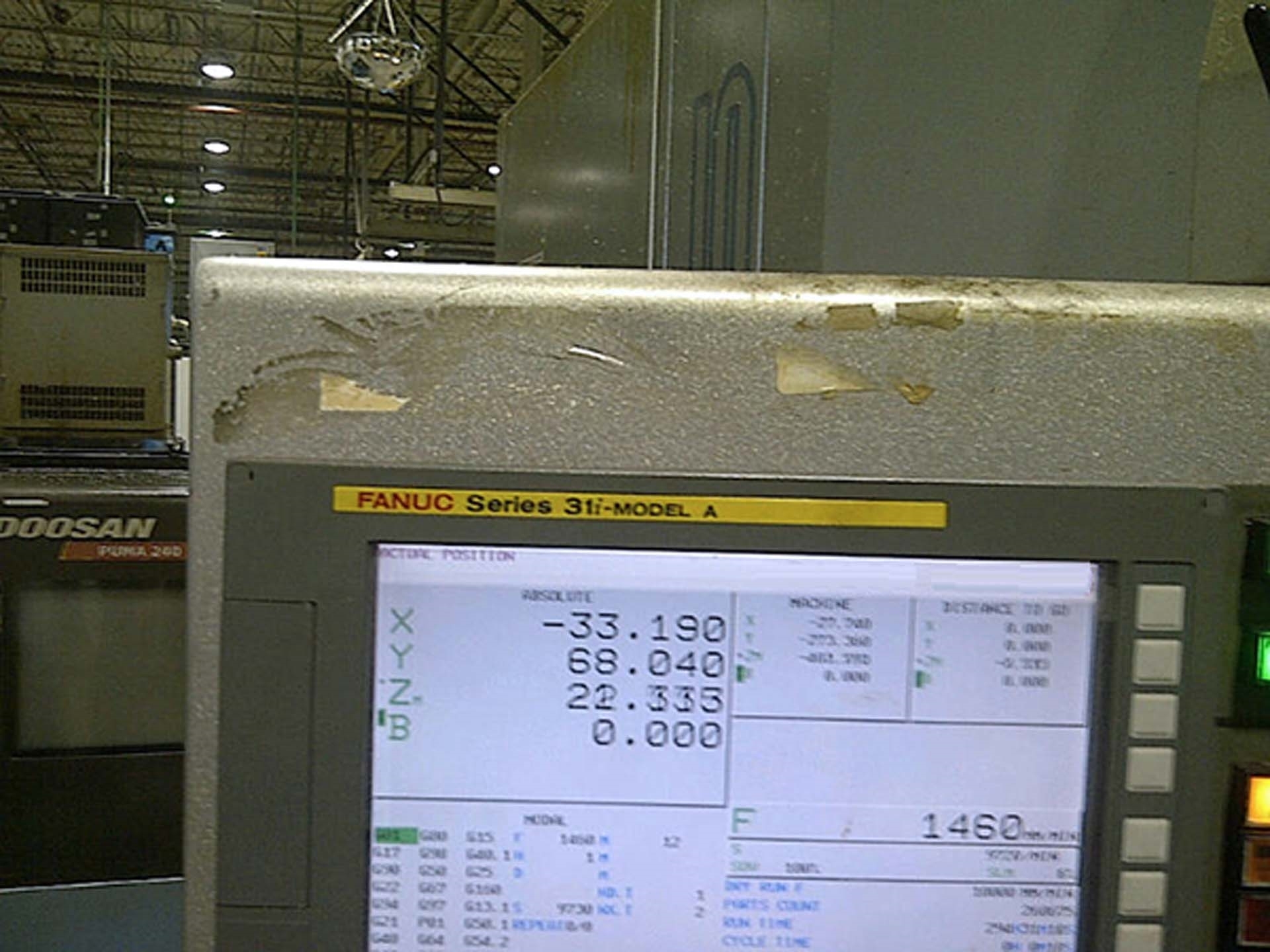

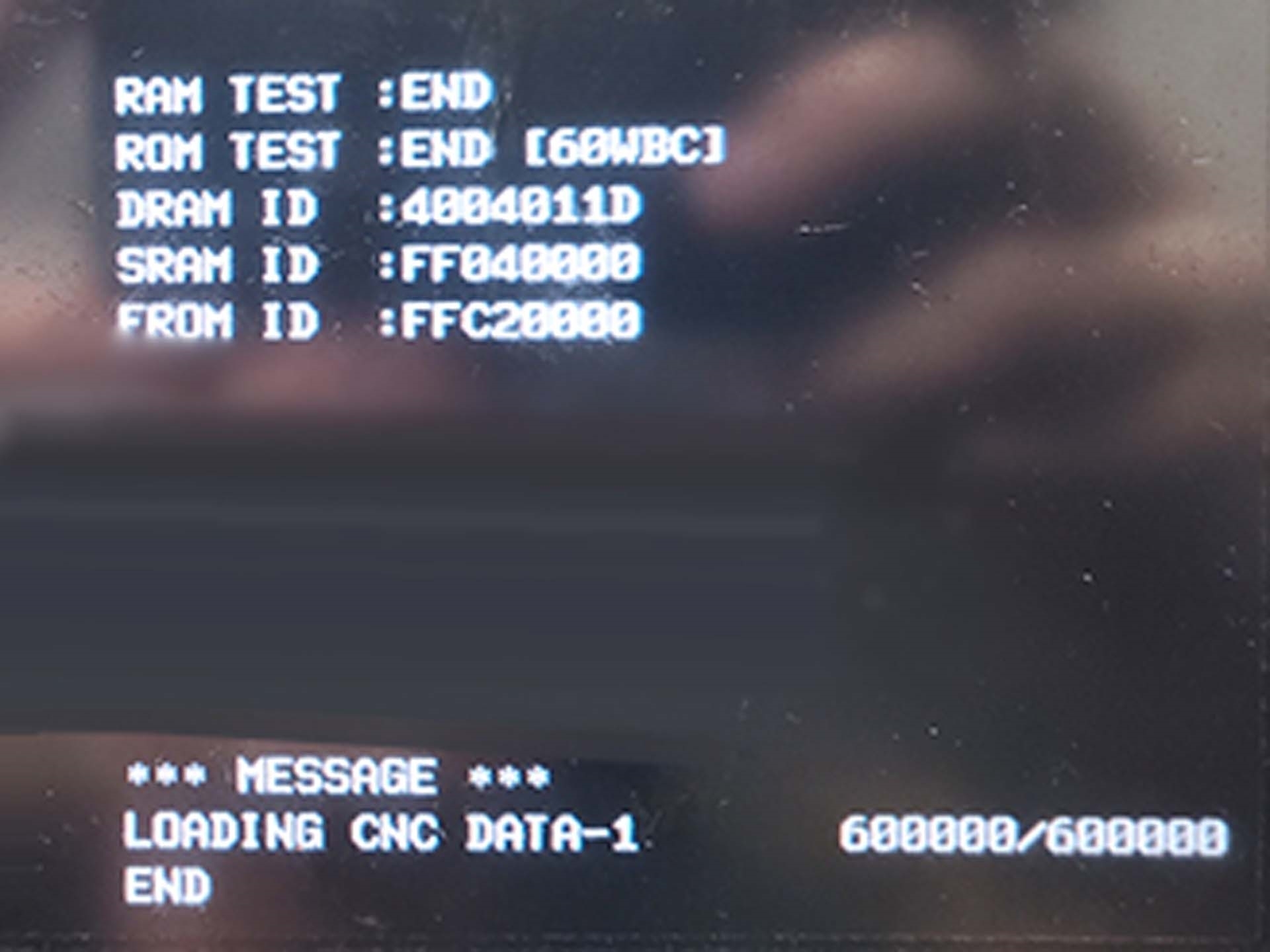

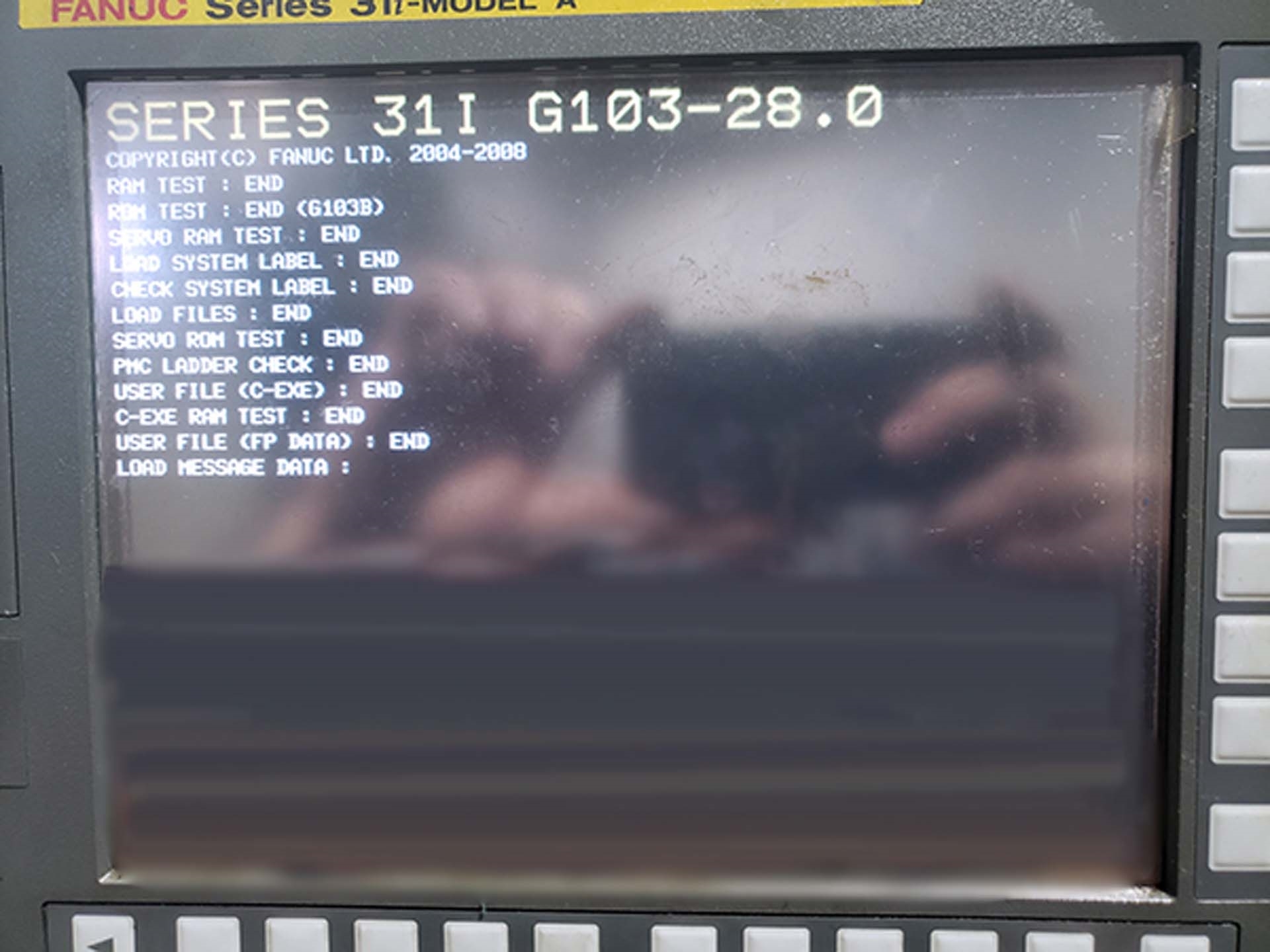

Controller: Fanuc 31i

X-Axis travel: 23.62"

Y-Axis travel: 23.62"

Z-Axis travel: 23.62"

Pallet size: 17.7" x 17.7"

Maximum workpiece swing: 24.80"

Maximum workpiece height: 35.43"

Maximum workload on pallet: 880 lb

Spindle output torque: 123 FT-LB

Spindle motor: 30 HP

Spindle taper

15000 RPM Spindle

HSK63 Taper

Rapid feed rates X/Y/Z: 1,968 IPM (50 m/min)

Table index: 360,000 Positions

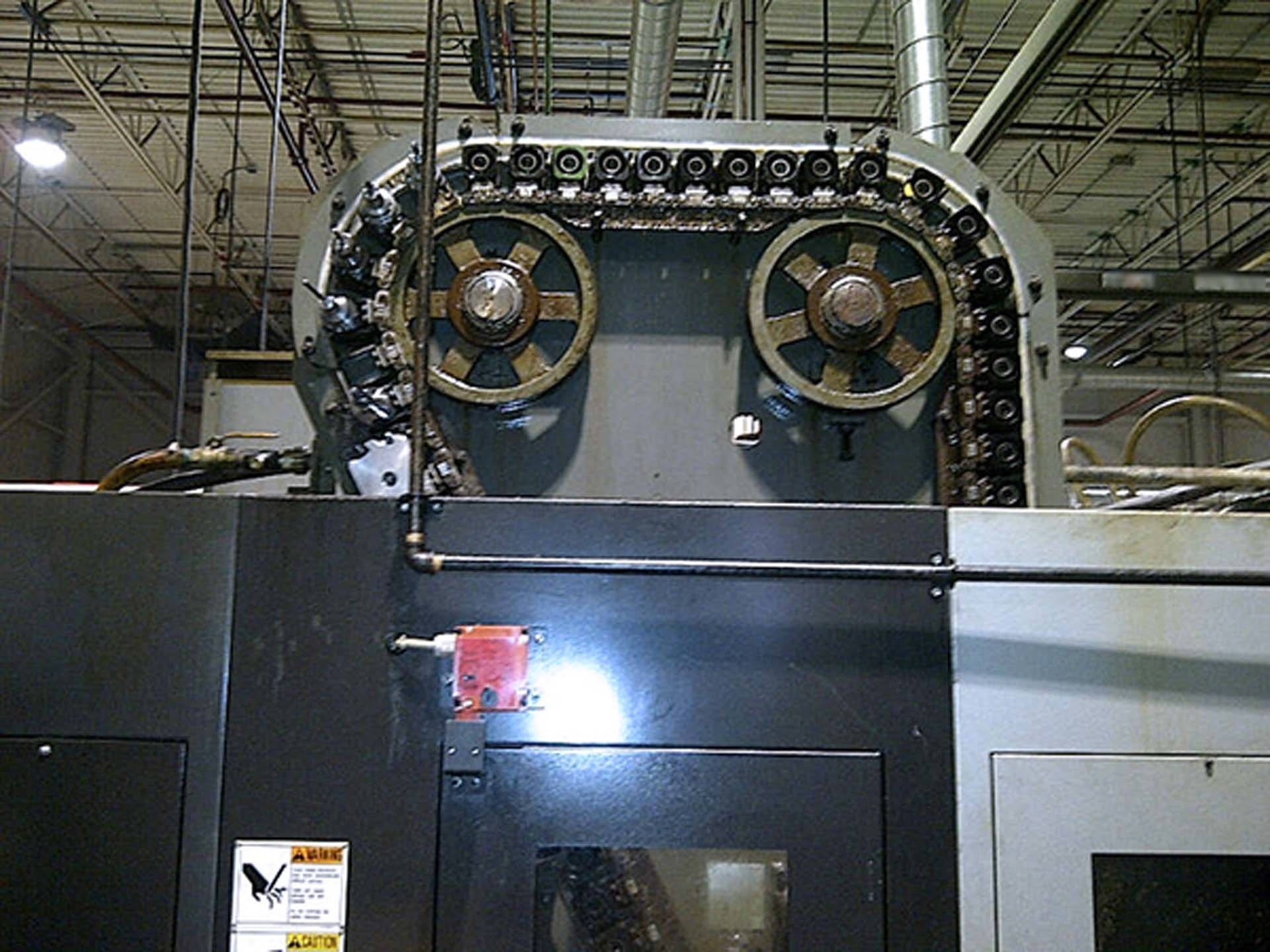

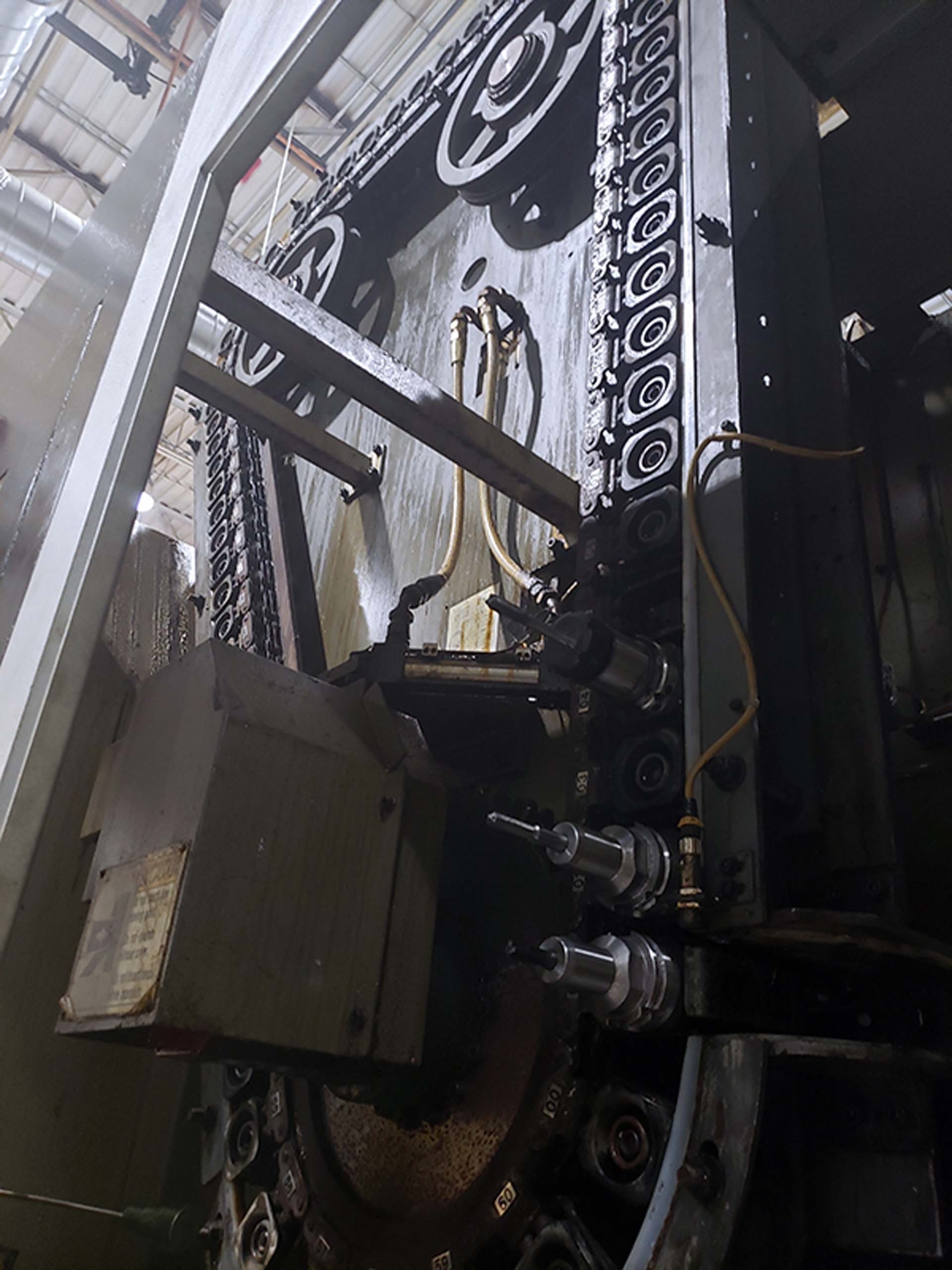

Tool storage capacity: 60

(60) ATC

(9) Tool Holders

CTS

2008 vintage.

TOYODA FH-450S is a high-performance, CNC, multi-axis mill-turn center that offers increased capabilities, precision and quality for manufacturing a wide range of automotive and aerospace components. FH-450S has a large working envelope, allowing for high-speed machining of large parts with a maximum turning diameter of up to 460 mm and a maximum turning length of up to 635 mm. It is equipped with a powerful spindle, rated at 45kW, allowing it to handle complex machining processes with a higher demand on speed and precision. It is also powered by a highly rigid, rigid-bed design and the latest Fanuc 0i-TD Series CNC to provide superior accuracy and smoother cutting. It can also be equipped with an HPCAT automation equipment for increased production efficiency. This automation system utilizes an intelligent tool management unit as well as a simple, automated part preparation process to ensure consistent accuracy and finish. It also features a parts washing and cleaning machine for improved surface finish and contamination-free components. TOYODA FH-450S provides a compact design for large part machining in a smaller space without compromising accuracy, thanks to a modern thermal-symmetric structure, vibration cancelling design, as well as a retractable chip guard for improved cutting flushing. It is also designed with an optional coolant-through spindle for fast chip evacuation and an optional spindle oil cooling tool to ensure better thermal management. FH-450S utilizes advanced digital signal processing and motion control algorithms, providing exceptional and dynamic acceleration for smoother, more precise motion. It also features automatic tool-setting capabilities for reduced set-up time and increased reliability. This advanced mill-turn center equips with the most ergonomic design, industry-leading bed-level accuracy and a high-rigidity spindle. Thus, precision parts with high accuracy and superior surface finish can be produced in the required quantity with consistent quality. TOYODA FH-450S is an ideal machine tool for plants that demand high-speed, precision machining.

There are no reviews yet