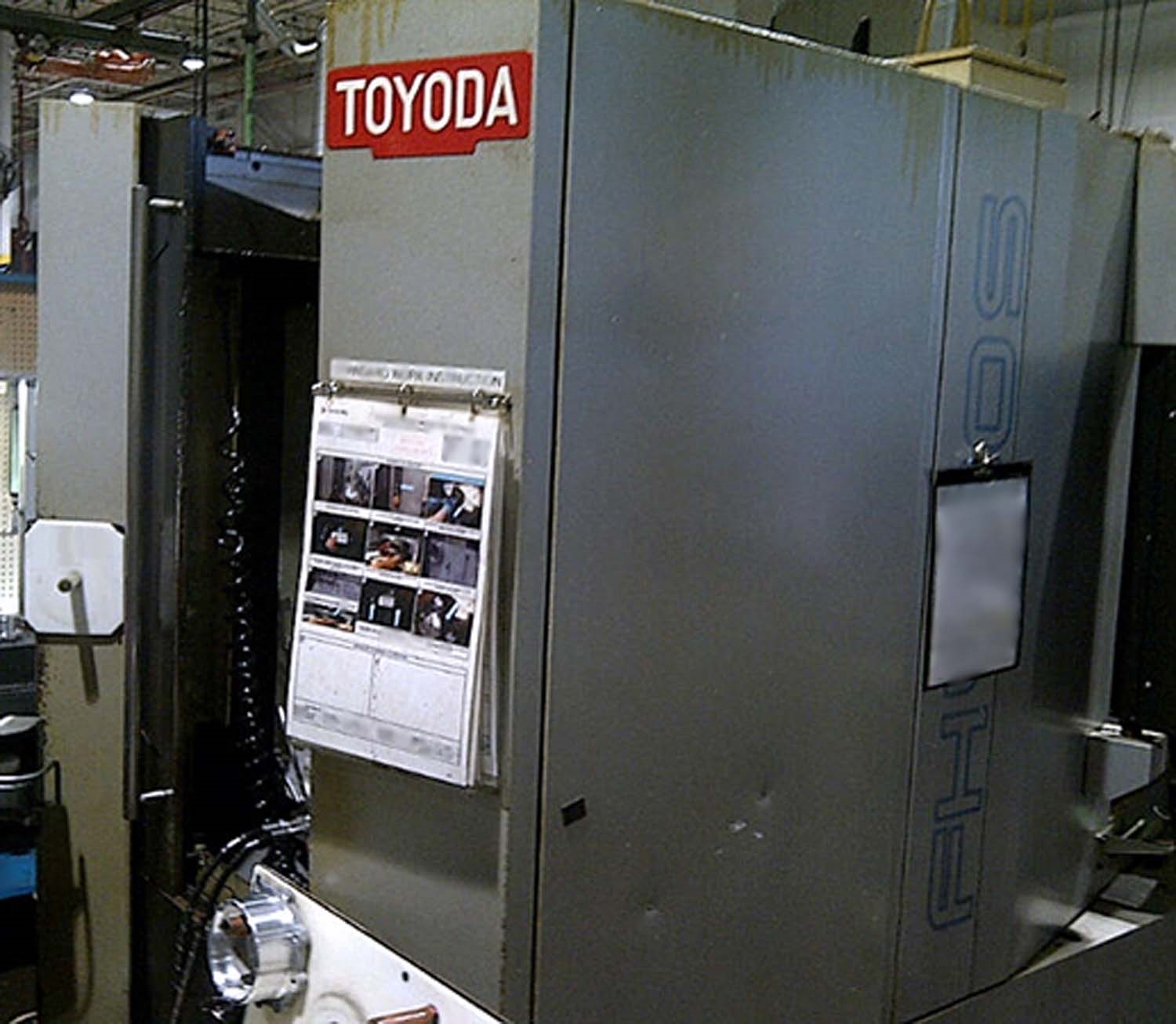

Used TOYODA FH-450S #9262378 for sale

URL successfully copied!

Tap to zoom

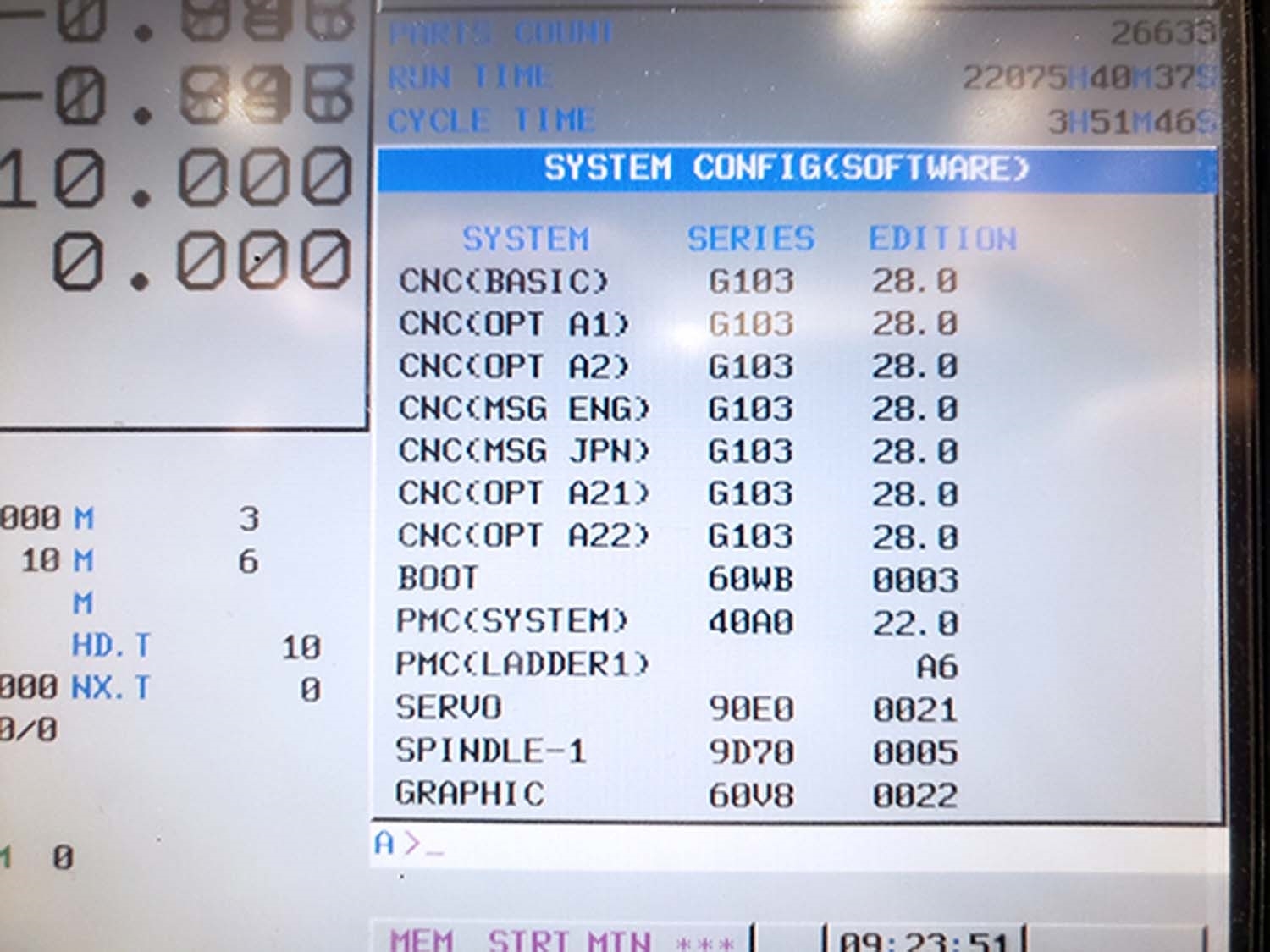

ID: 9262378

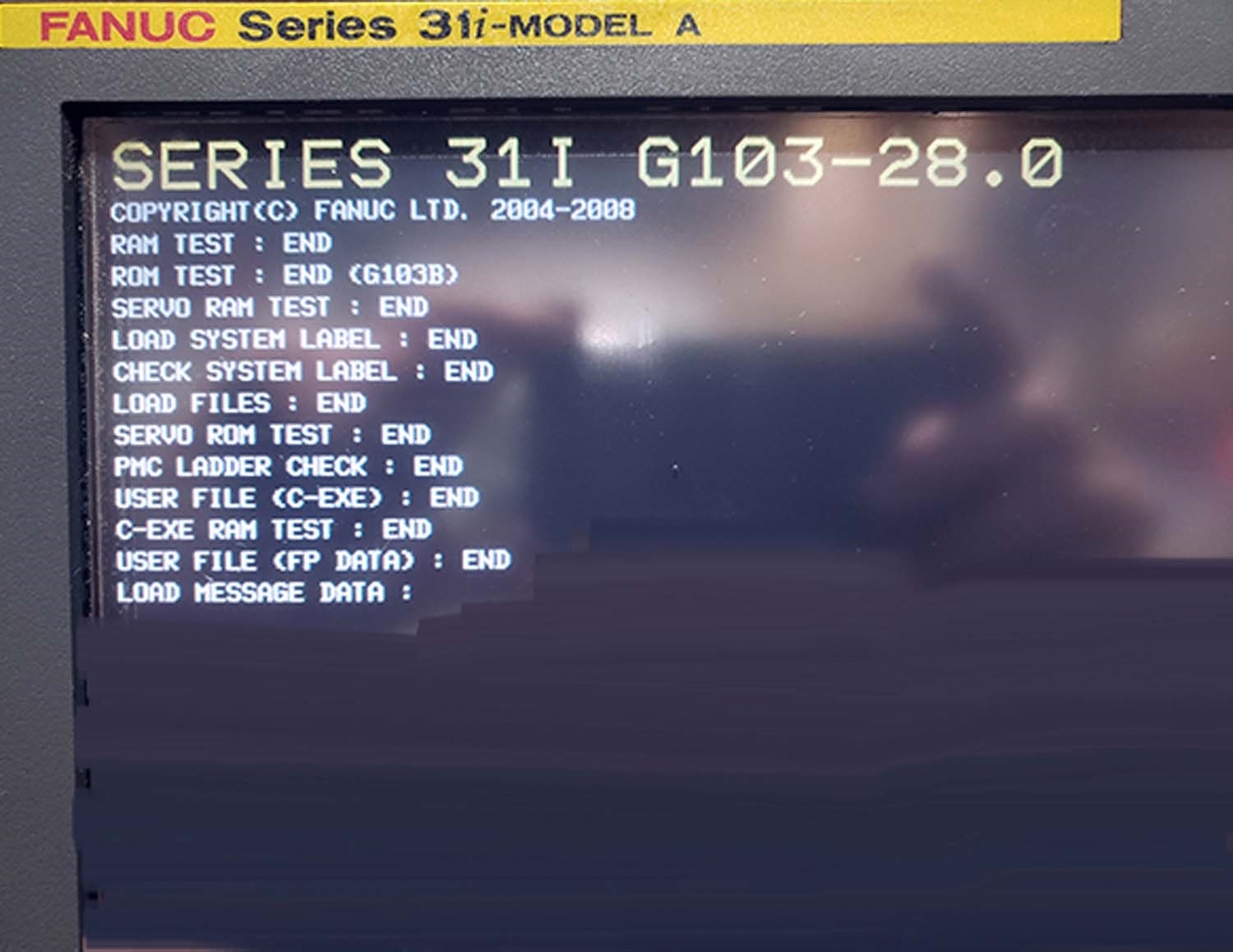

Vintage: 2008

Horizontal machine center

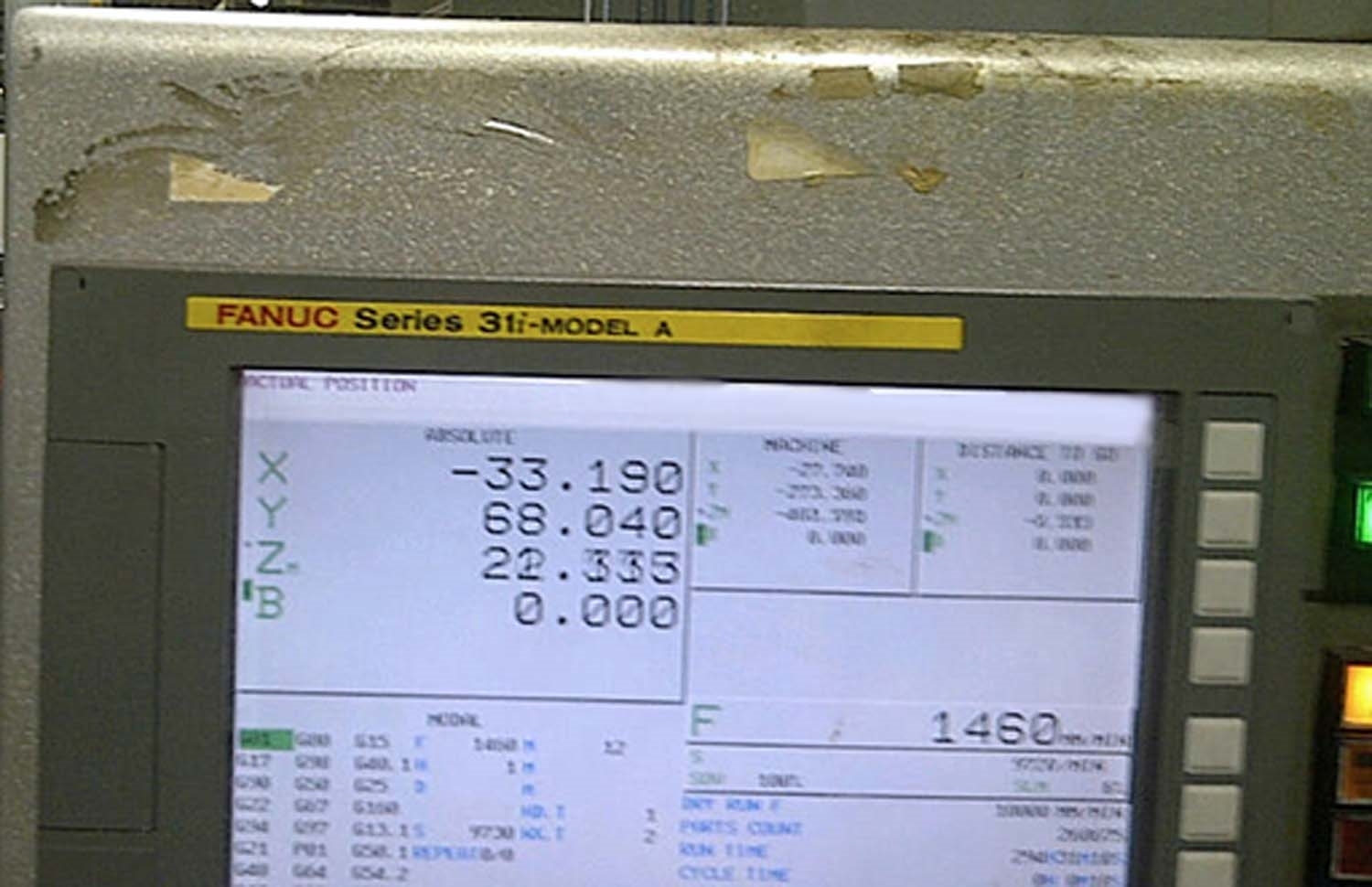

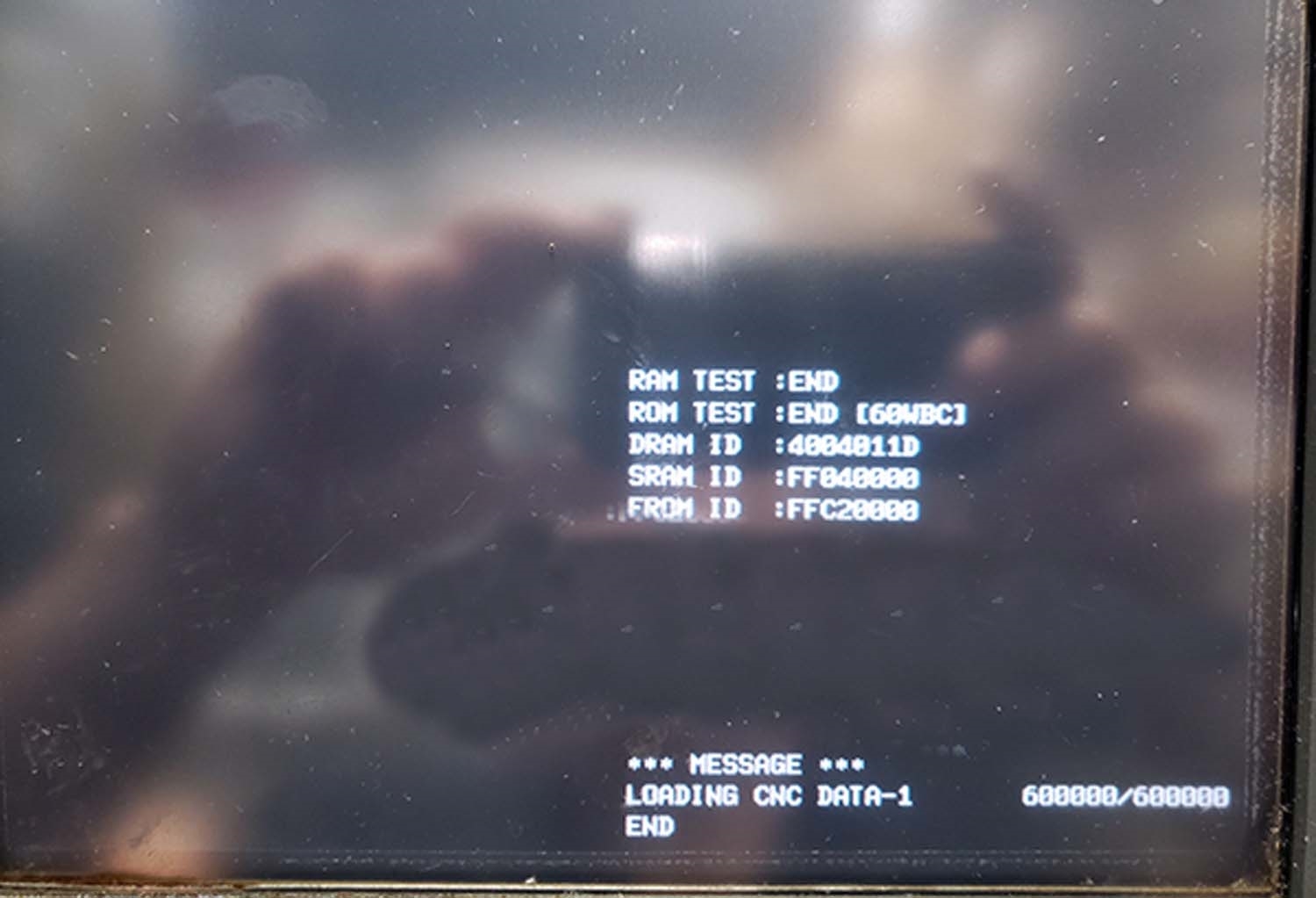

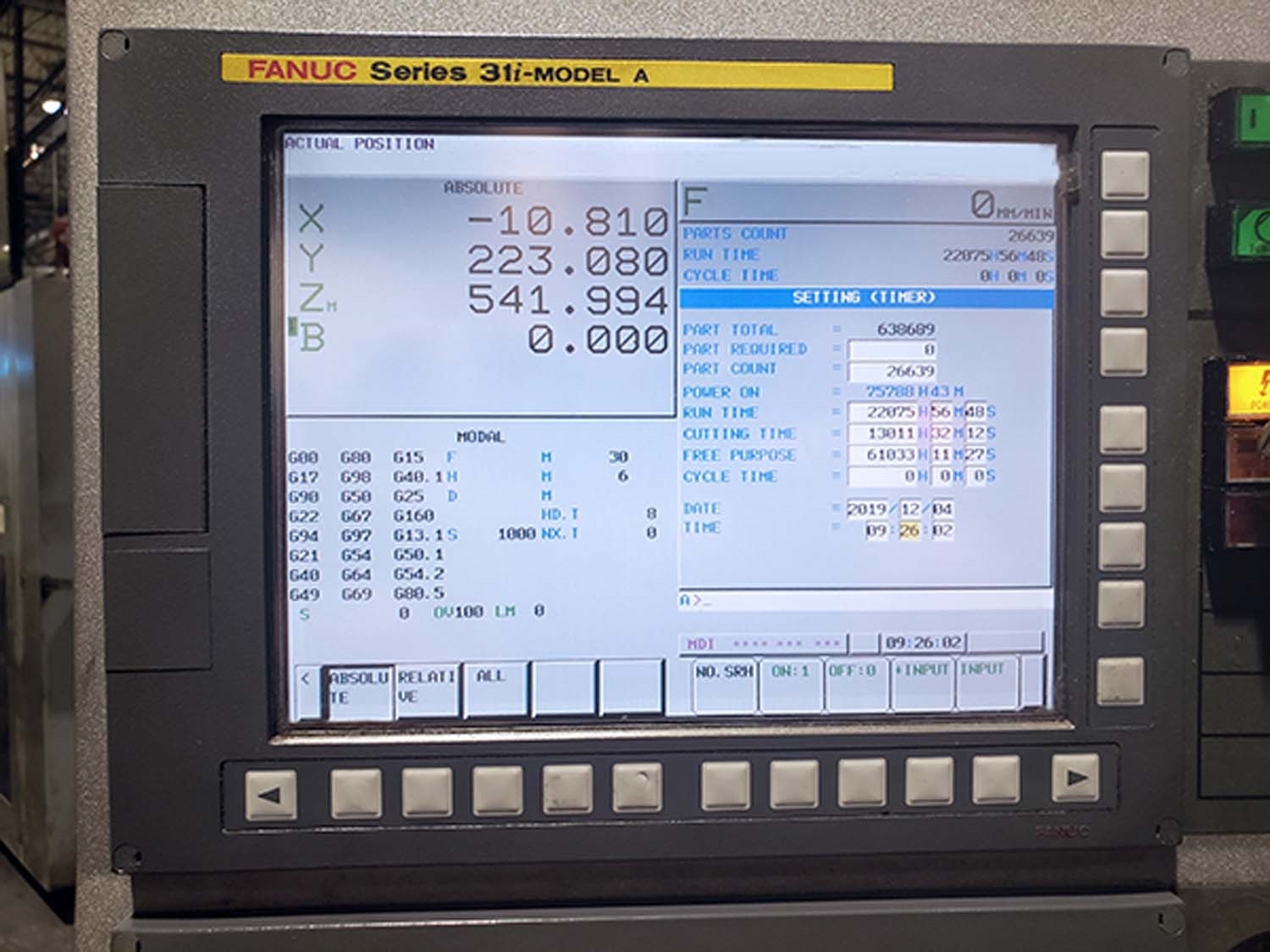

Controller: Fanuc 31i

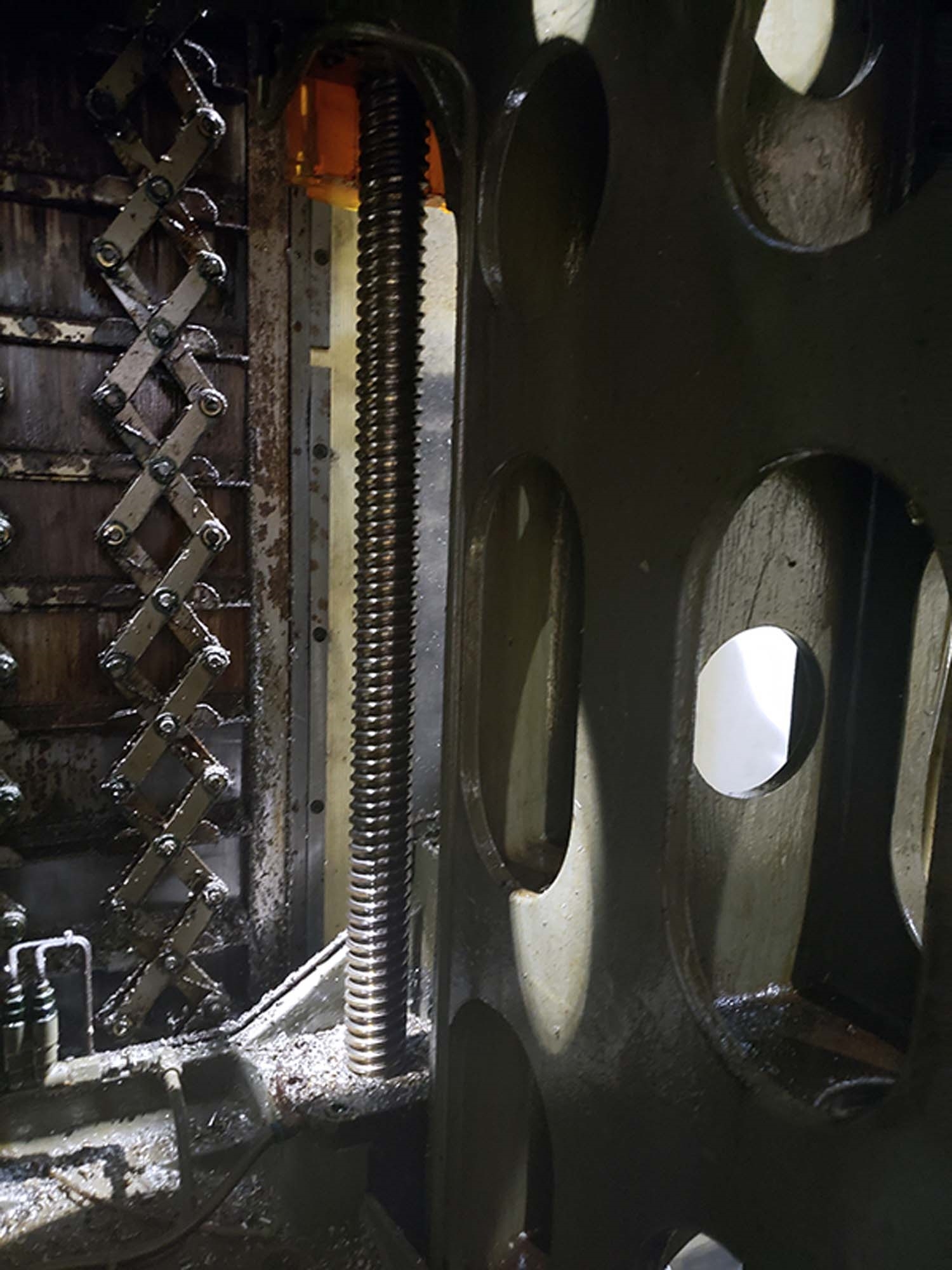

X-Axis travel: 23.62"

Y-Axis travel: 23.62"

Z-Axis travel: 23.62"

Pallet size: 17.7" x 17.7"

Maximum workpiece swing: 24.80"

Maximum workpiece height: 35.43"

Maximum workload on pallet: 880 lb

Spindle output torque: 123 FT-LB

Spindle:

30 HP, 15,000 RPM (0-15,000 IN 1.9 Sec)

30 HP, 20,000 RPM (0-20,000 IN 2.4 Sec)

Rapid feed rates X/Y/Z: 1,968 IPM

Table index: 360,000 Positions

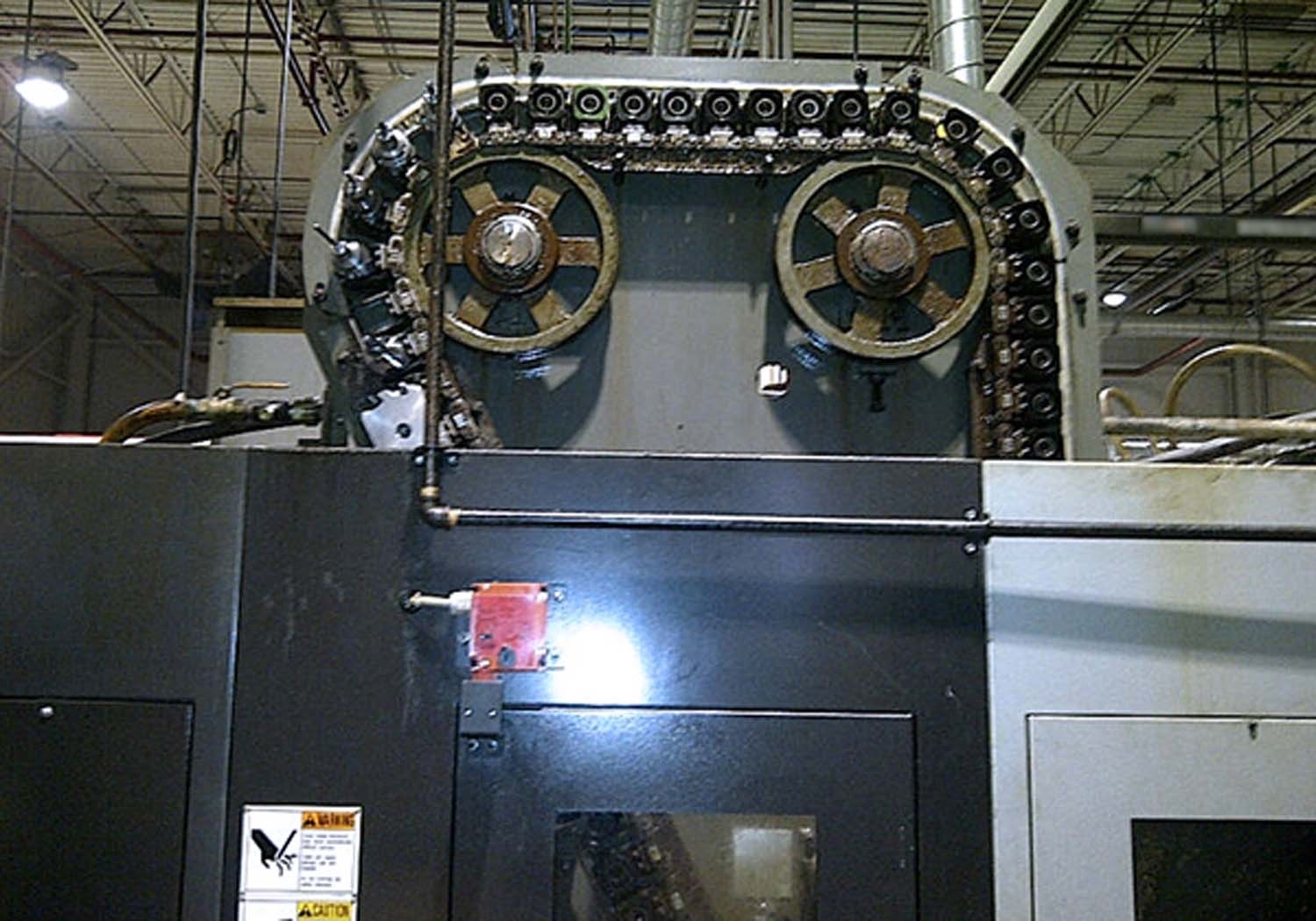

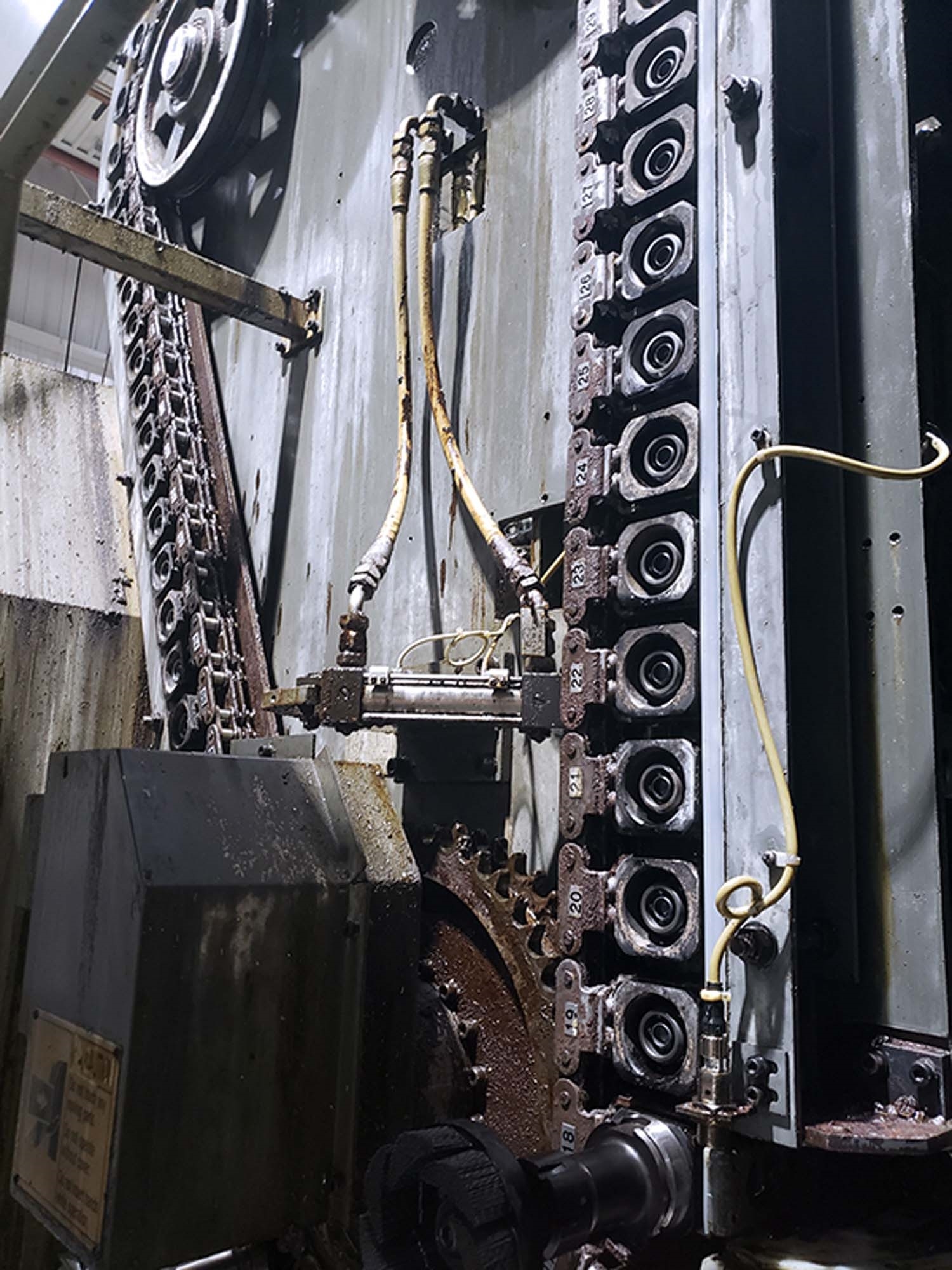

Tool storage capacity: 60

15000 RPM Spindle

(9) Tool Holders

HSK63 Taper

(60) ATC

CTS

2008 vintage.

TOYODA FH-450S machine tool is an ultra-high-precision high-speed machining center with a spindle speed of up to 30,000 rpm. The machine is capable of achieving extremely tight tolerances along with excellent surface finishes. It has a table size of 450mm x 1275mm with up to 24" x-axis travel, 18" y-axis travel and 20" z-axis travel. This allows for the production of complex components quickly and accurately with reduced cycle times. FH-450S is equipped with a 20HP, double-contact high-speed spindle with integral motor, and 9.5" of spindle nose to table height to allow for more clearance for tools. This can be utilized with an ATC with a carousel-style magazine that can hold up to 40 tools and provide fast tool change times. It also has an RS-232 interface for improved communication with CAD/CAM systems, as well as a USB port for easy data transfer. The machine features a high-speed, high-precision feed system that can be programmable to reduce vibration during machining operation, resulting in improved accuracy and slighter surface finish. Through the use of on-board CNC functions, such as rigid tapping, corner R/C and automatic corner control, the machine can efficiently and quickly complete jobs with reduced cycle time. Additionally, the CNC functions also provide a range of spindle speeds and feed rates for a greater range of machining needs with minimal to no programming. TOYODA FH-450S is specifically designed for hard milling and die/mold applications that require superior finish and accuracy, and can also be used to machine materials such as aluminum, steels, titanium, and special alloys. FH-450S has a cast iron frame which helps to reduce vibration and increase cutting stability. The machine is also equipped with a larger way system and heavier ways, which in turn, ensure the highest rigidity of the machine and excellent machining accuracies. Overall, TOYODA FH-450S is an excellent choice for high-speed hard milling and high-precision die/mold machining. The high-speed, high-precision feed system and variety of CNC functions ensure high accuracy and repeatability, while the large table size, rigid frame, hefty ways, and spindle power provide excellent performance. Furthermore, the USB and RS-232 ports allow for easy data transfer and improved communication with CAD/CAM systems. For these reasons, FH-450S machine tool is a great choice for hard milling and die/mold machining, and it is sure to provide an excellent ROI.

There are no reviews yet