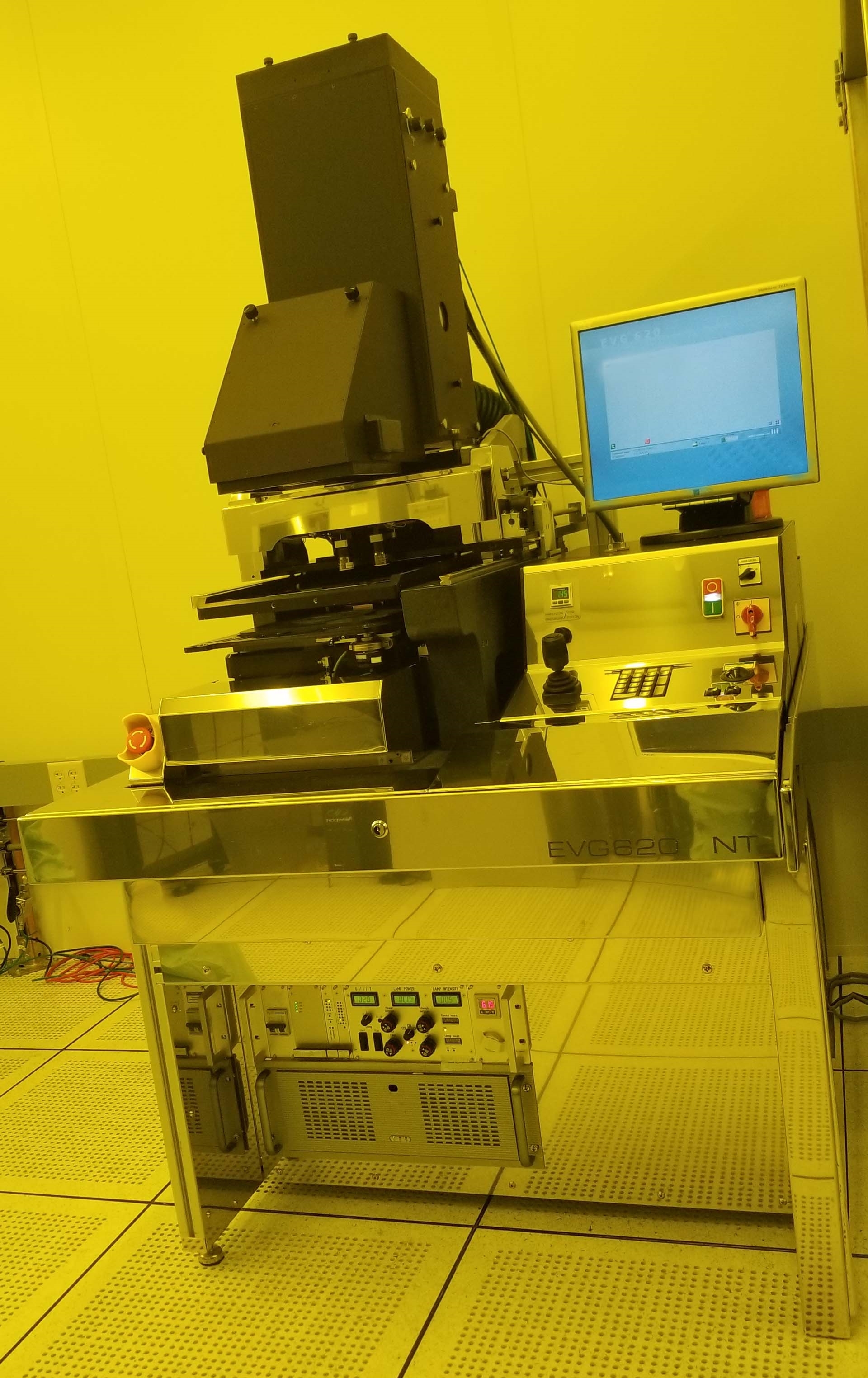

Used EVG / EV GROUP 620NT #9191006 for sale

URL successfully copied!

Tap to zoom

ID: 9191006

Wafer Size: 6"

Vintage: 2011

Automated double side lithography system, 6"

Exposure modes:

Hard

Soft

Vacuum contact

Proximity

Separation distance: 0-300 μm adjustable

Wafer thickness: 0.1-10 mm (For top side configuration only)

Semi automatic loading

Mechanical pre-alignment on chuck

Quick change of mask and chuck

Flat screen for operator interface and alignment functions, 17"

PC Controlled operating environment

Granite base frame construction

Active vibration isolation

Password protected access levels:

Operator

Engineer

Maintenance

Back side alignment of wafers:

Mounted carrier

Deep etched back side alignment marks

Supports measuring of structures

Cross hair distance

Resolution with 10x objectives: 1.1 μm

Light source NUV: 500 W-1000 W

Lamp house: 350 W / 500 W Hg lamp

Optical sets in NUV range: 280-450 nm

Optimized parallel light:

±2%, 4"

±3%, 6"

UV Probes:

Diameter: 44.5 mm

Height: 16 mm

Optical set for wave length: 350 nm-450 nm

Light sources: NUV / DUV

Field lens, 6"

Dielectric mirror

Fly's eye lens

Alignment stage fully motorized

Fully motorized X, Y, Theta & Z alignment stage

With DC motor controllers

Automatic wedge compensation system

Optimized print gap control

WEC Contact force: 0.5-40 N adjustable

Top side microscope:

Motorized split field microscopes in visible light

With high resolution CCD cameras for top and bottom side

Travel range:

X: 30 (8)-150 mm

Y: -70 / +70 mm

Storage of objective positions

Digital zoom: 2x / 4x

Image magnification for fine alignment

(2) Objectives: 10x (3.6x - 20x)

Bottom side microscope:

Motorized split field microscopes in visible light

With high resolution CCD cameras

Bottom side alignment

Travel range:

X: 68 (48) mm-150 mm

Y: ± 12 mm

Digital zoom: 2x / 4x

Image magnification fine alignment with objectives

(2) Objectives: 10x (3.6x - 20x)

Rack unit EVG 620 mask aligner systems:

Integrates EVG 620 desktop alignment system

Vibration isolated

Robotic auto load system

Robot module for auto load cassette to cassette:

Size: 4"-6"

With non contact optical prealigner for wafers

With flat and notch

Standard: With vacuum from bottom side

Robot control fully integrated to EVG 620

Graphical User Interface (GUI)

Cassette station:

Send

Receive

Standby

(5) Cassette stations:

Cassette present sensor

Cassette empty sensor

Semi standard wafer cassette sizes

IR Light source: Bottom side objectives

IR-Transparent substrates

Bottom side microscope: IR Light source manipulation

IR Alignment of wafer to mask using top side microscope

IR Lamp position with recipe

Active cooled IR light source

Manual and automatic alignment processes

Usage of special IR objectives on topside microscope

Reduces bottom side microscope travel range

Pick and place handling option:

Programmable send / receive / standby cassette configurations

Up to 75 wafer processing on handling modules:

(3) Cassette stations

No operator intervention

125 wafer processing on handling modules:

With (5) cassette stations

No operator intervention

Hard UV-Nano imprinting:

UV-NIL Processes with hard stamps (Quartz glass)

Top chuck, 1" stamps (in diameter)

Bottom chuck:

Microscope slides:

10 x 10 mm

15 x 15 mm

25 x 75 mm

Diameter: 2"-4"

Soft UV-NIL and μ-CP:

PDMS Stamp to be mounted on glass back plane (5" square)

Bottom chuck, 4"

Loading frame, 1" Stamp

Contact free wedge compensation with spacers

Adjustable contact force for vacuum printing process

Top chuck with quartz windows for UV curing of resist

Optical alignment of stamp and substrate in two steps:

Separation of stamp and substrate: Rough alignment

Soft contact of stamp: Fine alignment

Vacuum contact: 100 - 850 mbar

Mask holder for 5" x 5" masks with loading frame

Bottom loading system

with automated vacuum transfer

Hard coated & lapped surface finish for mask contact area

Mask holder for 7" x 7" masks with loading frame

Bottom loading system with automated vacuum transfer

Hard coated & lapped surface finish for mask contact area

Universal wafer chuck, 4"

With spacers

For automated handling

Hard coated & lapped surface finish for wafer contact area

Universal wafer chuck, 6"

With spacers

For automated handling

Hard coated & lapped surface finish for wafer contact area

Manual filter changing unit without filter / carrier

Includes:

Bond alignment

Signal tower

Does not include cassette load

2011 vintage.

EVG / EV GROUP 620NT is a mask aligner designed to support advanced ionizing radiation (e-beam) and optical lithography requirements in semiconductor fabrication and other industries. Its aligner provides precise alignment of photomask patterns to the wafer surface, ensuring accurate replication of features and uniformity of performance of the device. EVG 620NT features an advanced two-beam equipment, which enables targeting and positioning of a wide range of patterns with subpixel accuracy and rock-solid stability. Its wide-angle optics provide unmatched field of view and allows alignment of large areas of patterns in one go. In addition, the system provides an efficient working environment with a modern GUI and several tools for easy operation, including robotics for handling of mask and wafer. The performance of theEVG EV GROUP 620NT is further enhanced by its high-resolution imaging unit, which features a 12k x 12k-pixel CCD area scan camera that captures images using nanometer-level resolution. An integrated micron-level auto stage is capable of providing tight registration accuracy and repeatability, so patterns can be positioned within a single-digit nanometer accuracy over the entire field of view. 620NT is built with expandable modular components, which allows users to easily upgrade or modify the equipment when needed. Innovative architecture and dedicated data communication lines offer extremely fast imaging, with scan speeds of up to 10 megapixels per second. To keep up with the rapid changes in device manufacturing, further advances in the imaging machine are possible with an upgradeable hardware platform. EVG / EV GROUP 620NT is a powerful and reliable tool for those involved in the challenging task of creating and replicating advanced semiconductor features. Its combination of cutting edge optics, high precision imaging, rock solid platform, and upgradable hardware ensures an efficient working experience and a uniform, defect-free performance of the device.

There are no reviews yet