Used HTG 84-3 #9198923 for sale

URL successfully copied!

Tap to zoom

ID: 9198923

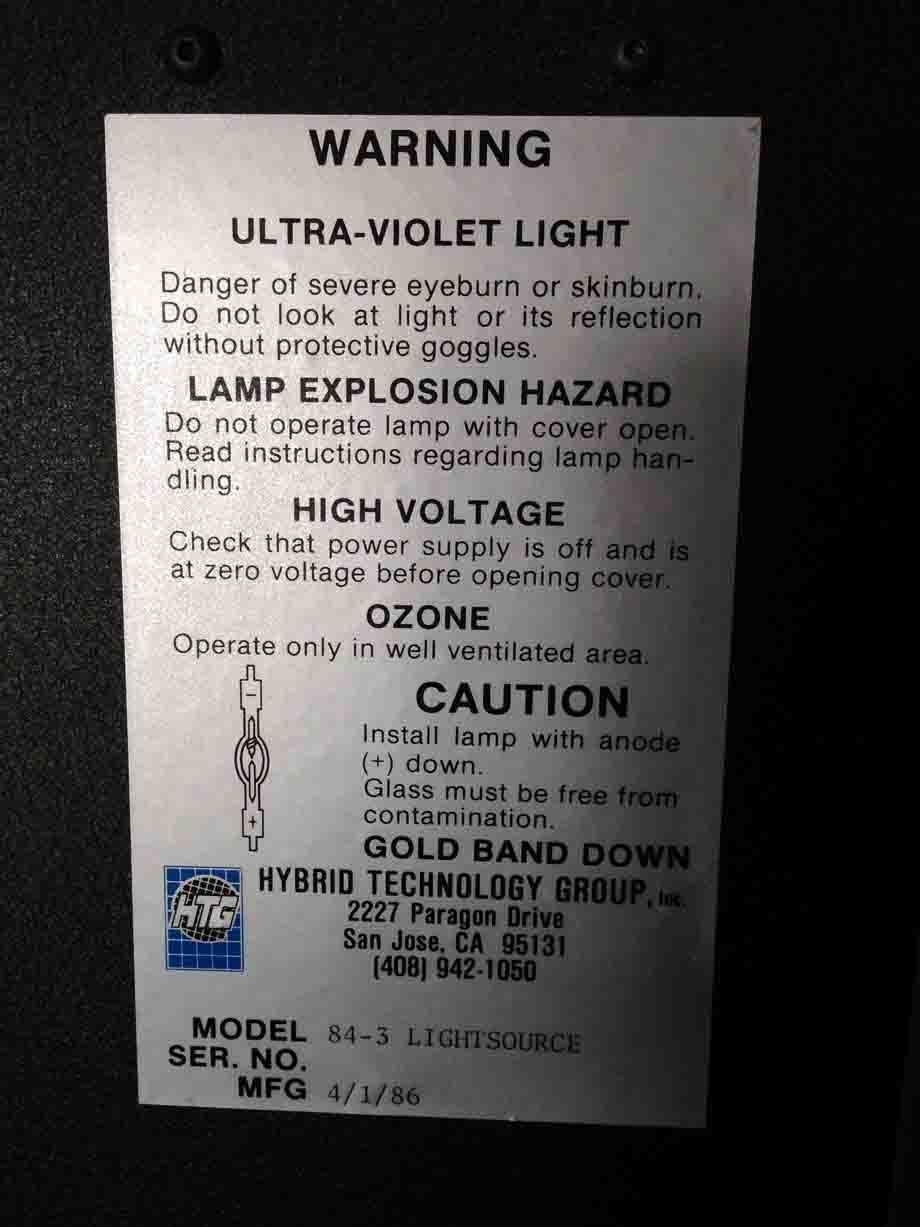

Vintage: 1986

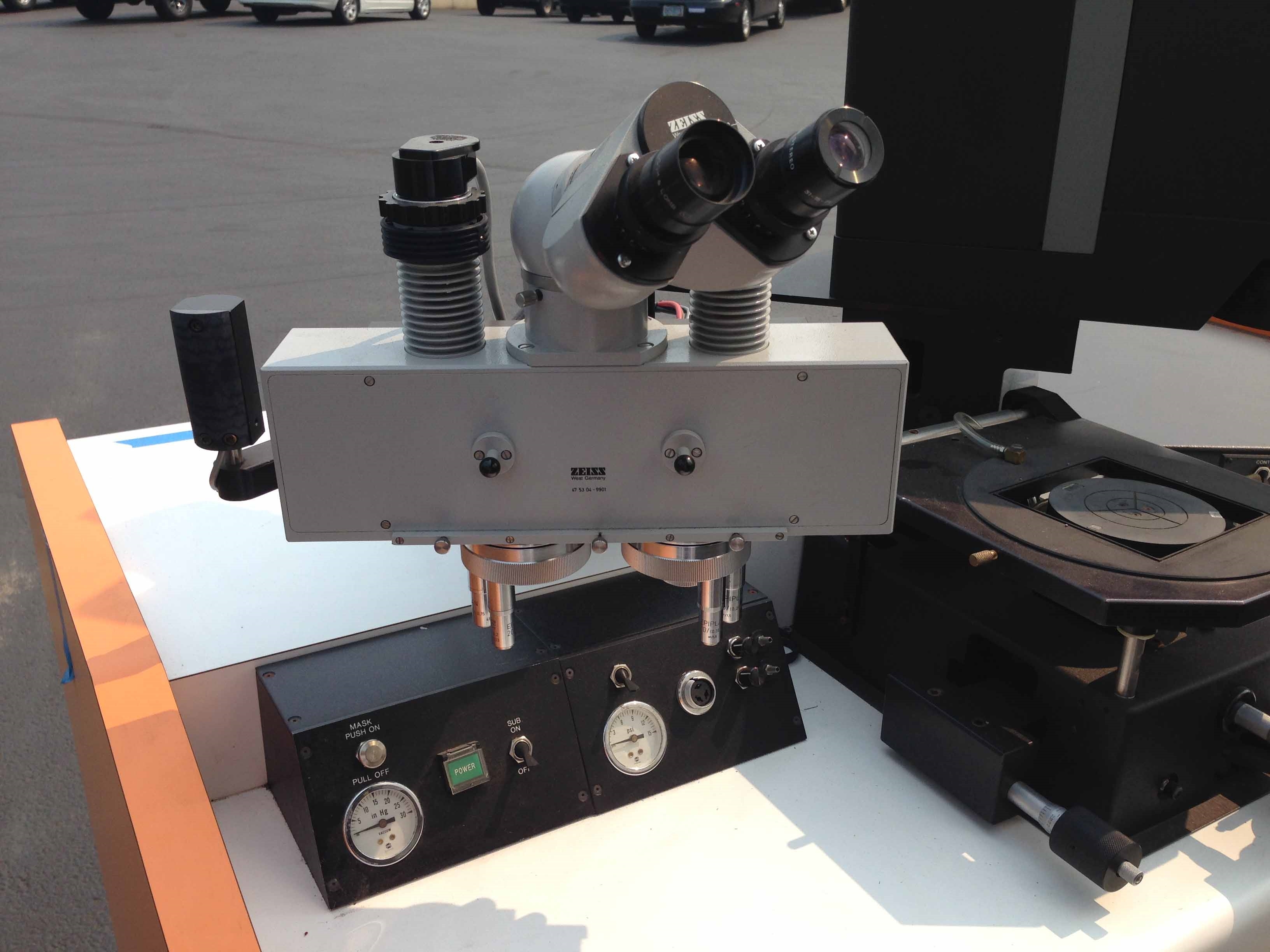

UV Mask aligner

With microscope

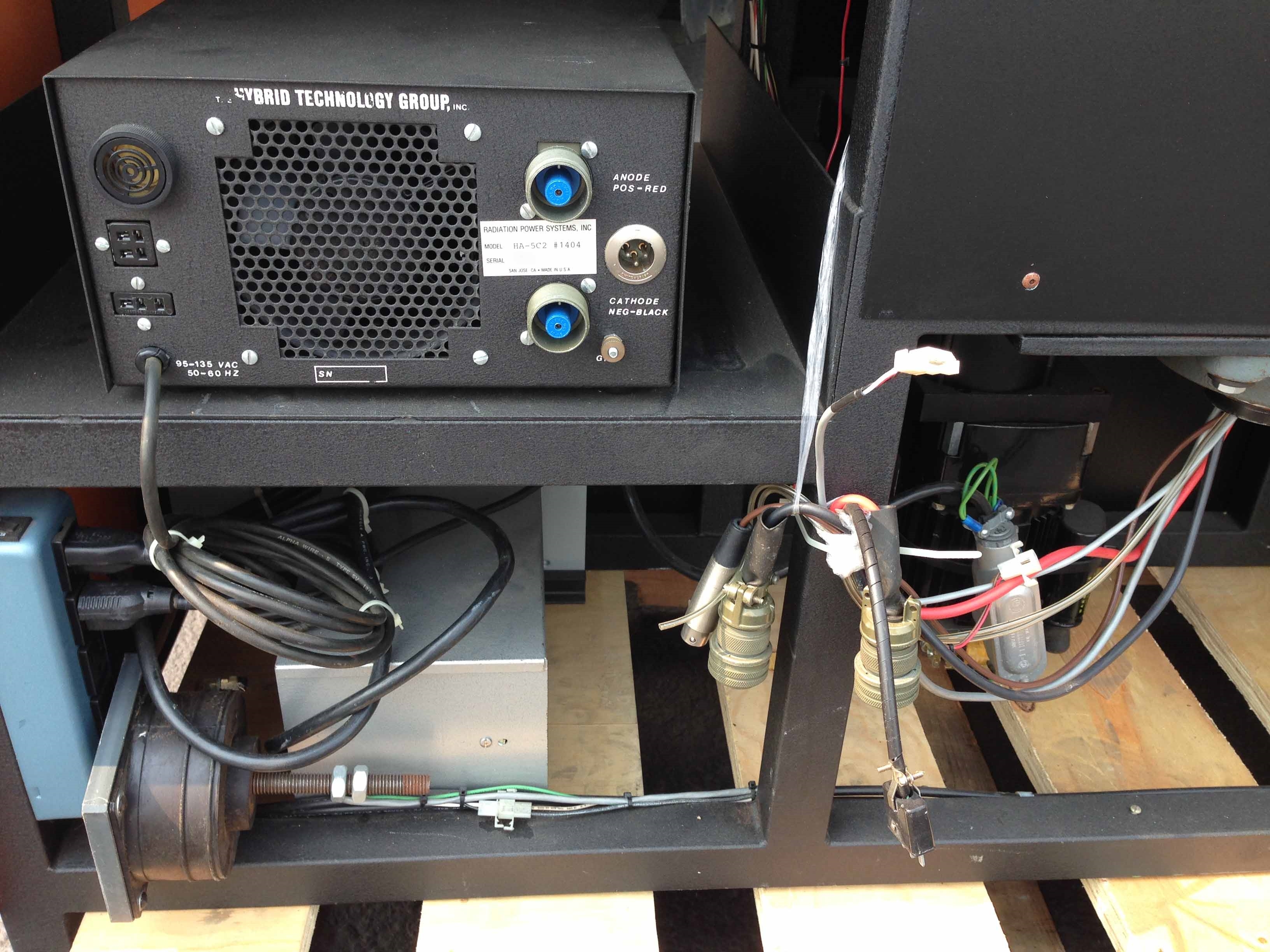

UV Lamp power supply

High resolution

Sub-micron printing

Contact and proximity exposures

Scale production alignment capability

Silicon, GaAs, LiNb, InP

Consistent printing:

Wafers

Rectangular substrates

Odd sized / Brittle materials

Single or split field viewing

Up to 600x magnification on the optics

Alignment accuracy: ±1 µm

Precise wafer to mask leveling

Highly collimated UV/deep UV exposure systems

Two channel intensity controlling power supply systems

Stationary alignment tooling

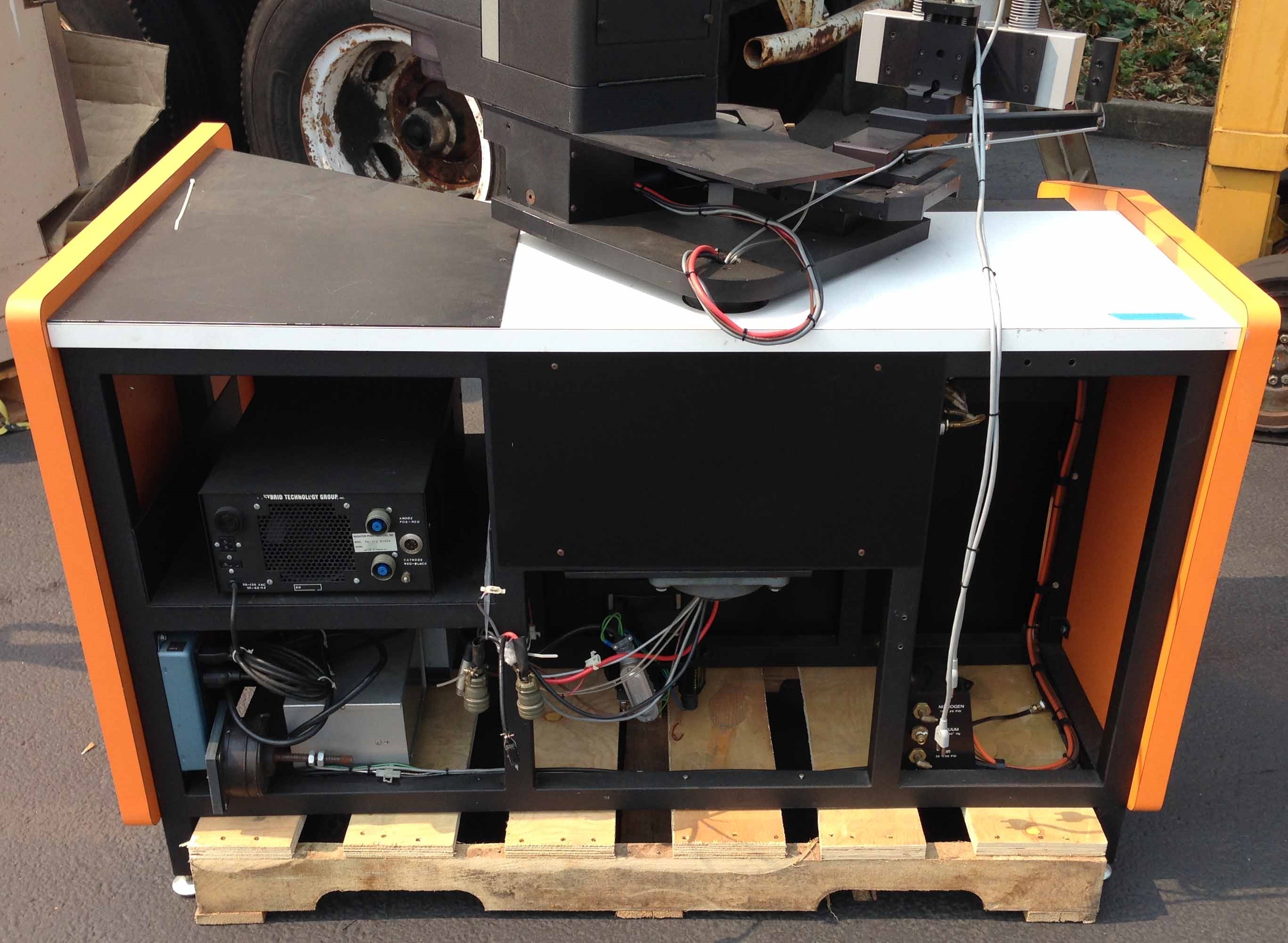

Vibration isolation console

Differential micrometers

Self planarizing chucks

Wafer chuck and mask holder included

Wafer chuck motions:

X, Y, Z and ø (direct drive)

Z-Axis adjustment: ±750µ

Air-bearing planarization system

Wafer / Substrate size: Up to 6.0" wafers / Square substrates

Mask rotation: 180°

Mask size: 7.0" x 7.0"

Vacuum mask clamp

Pneumatic mask assembly lift

Front side alignment accuracy: <0.5µ

Printing resolution:

Near UV: <0.8µ

Mid UV: <0.4µ

Deep UV: <0.3µ

Control functions:

Power

Test

Substrate vacuum

Mask vacuum

Contact vacuum

Expose

Cycle

Skip

Mask lift

N2 Purge

Timer:

000.1 to 999.9 sec

0.1 increments

Gauges:

System vacuum

Contact vacuum

N2

1986 vintage.

HTG 84-3 is a mask aligner used in the manufacturing process of semiconductor devices. It is an advanced tool capable of aligning and patterning semiconductor masks with the highest precision and accuracy. The main components of 84-3 include a mask aligner main unit, a vacuum chamber, and a vacuum equipment. The mask aligner main unit is composed of an X-Y stage, a laser alignment system, and vacuum unit. The mask aligner main unit is responsible for moving the mask, laser projection machine and vacuum alignment stage to the appropriate location within the vacuum chamber. The laser projection tool consists of a laser source, a collimator, and a series of lenses that project laser beams onto the mask and wafer to align them. The laser source is normally a Helium-Neon (He-Ne) laser. The collimator is used to focus the laser beam onto small diameter of the mask or wafer. The laser projection asset also includes an inspection model, which is used to detect irregularities in the positions and shapes of the mask and wafer. The inspection equipment consists of a series of cameras that are capable of capturing images of the mask and wafer, and then comparing the images to pre-programmed data for errors. The vacuum chamber is used to seal the mask and wafer for accurate alignment. The chamber contains a vacuum system, which prevents a pressure buildup that can interfere with the accuracy of the alignment process. The vacuum unit also protects the mask and wafer from contamination by dust particles or other debris. HTG 84-3 is highly precise and accurate and is capable of aligning masks and wafers to within 0.0025mm accuracy. The machine is also fast, capable of aligning a mask and wafer within 0.2 seconds, and can be used for a variety of application, such as contact and non-contact masks. Overall, 84-3 is a versatile and reliable mask aligner that is designed to provide superior performance and accuracy. Its precision and accuracy make it a valuable tool for semiconductor device manufacturing.

There are no reviews yet