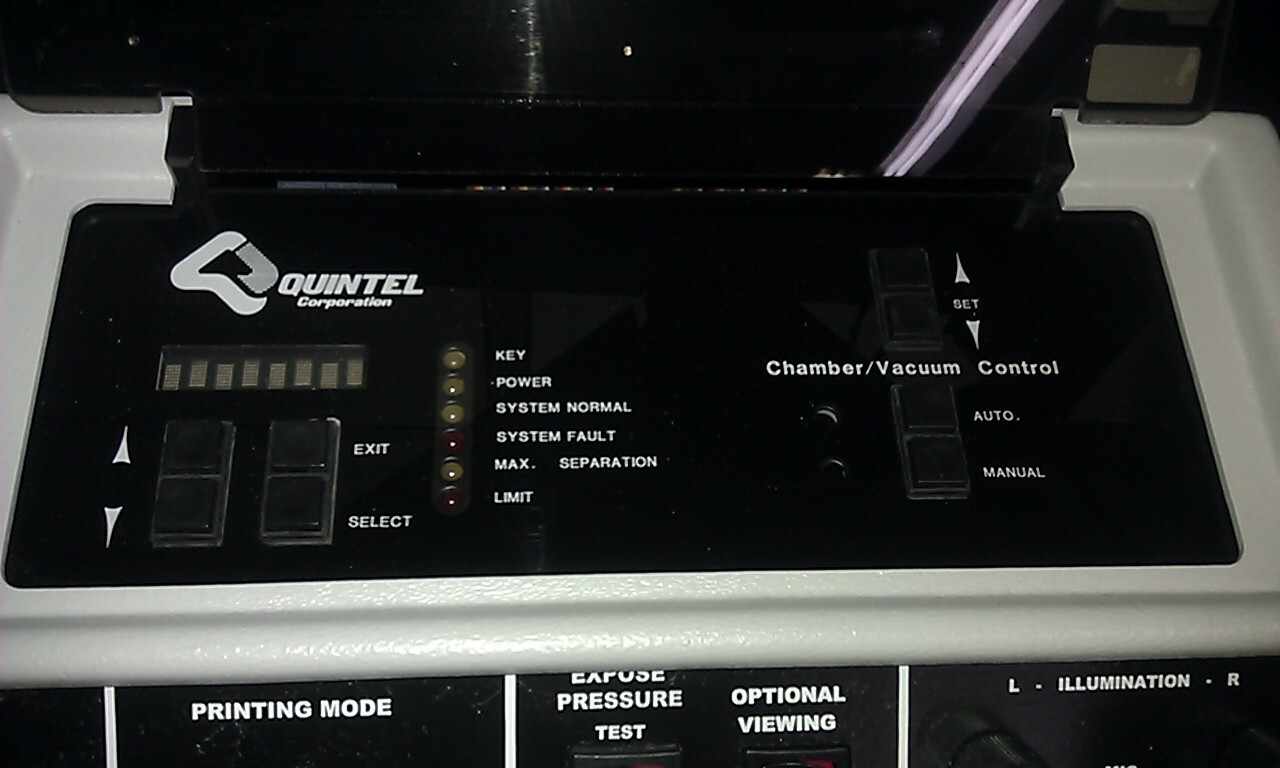

Used QUINTEL / NEUTRONIX 7000 #9058228 for sale

URL successfully copied!

Tap to zoom

ID: 9058228

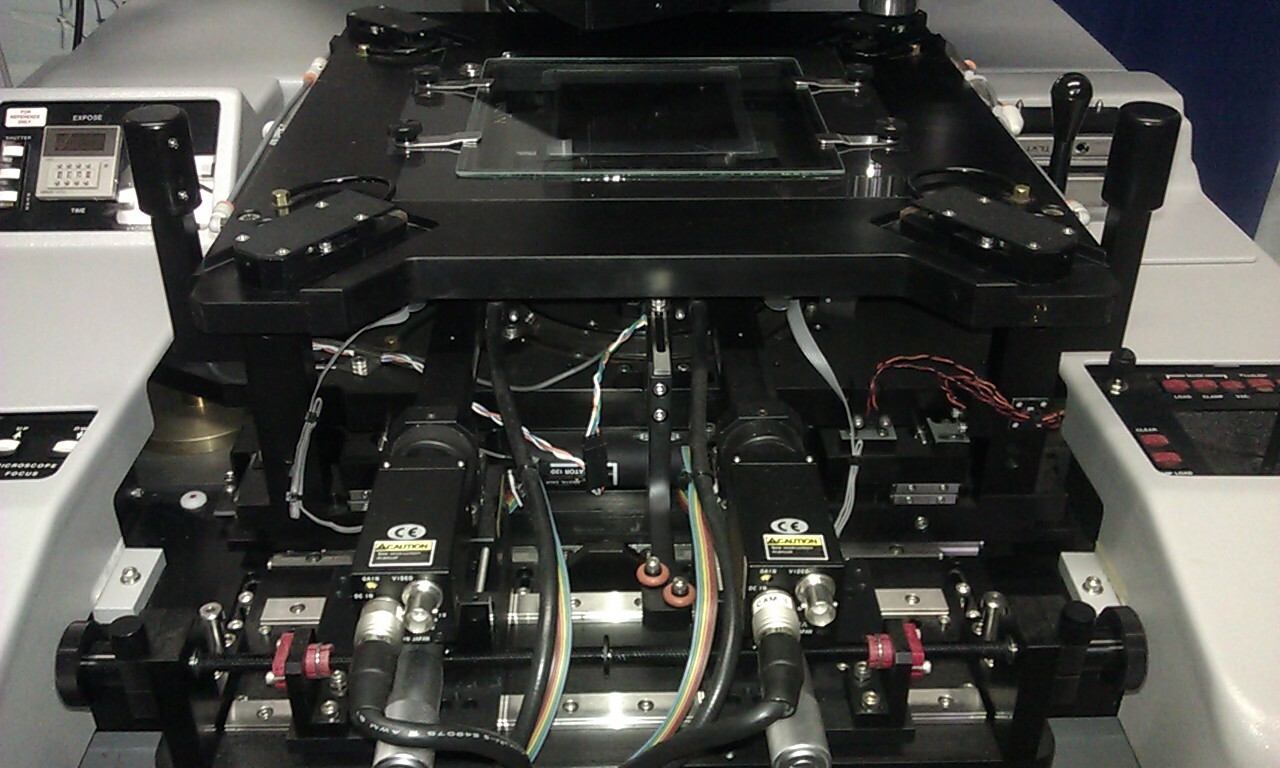

Wafer Size: 6"

High resolution mask aligner, 6"

Backside infrared alignment

Resolution: (1) Micron with vacuum contact.

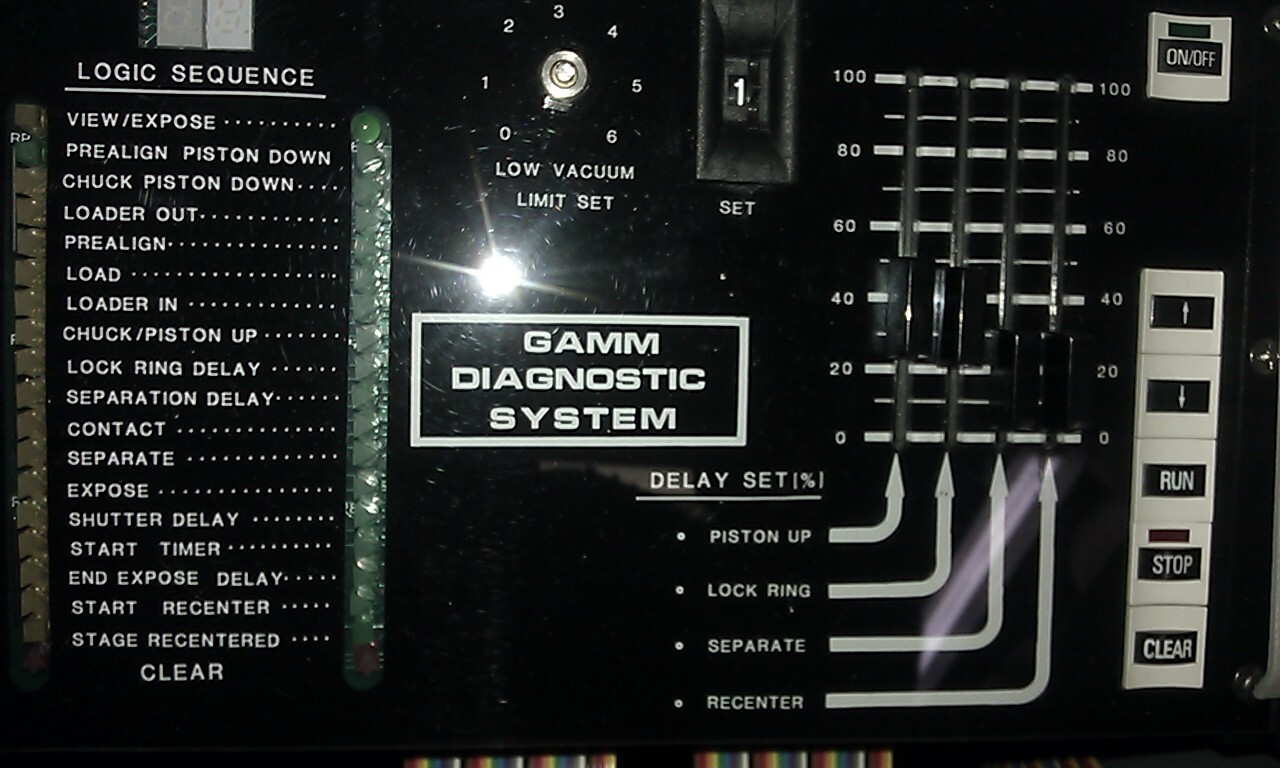

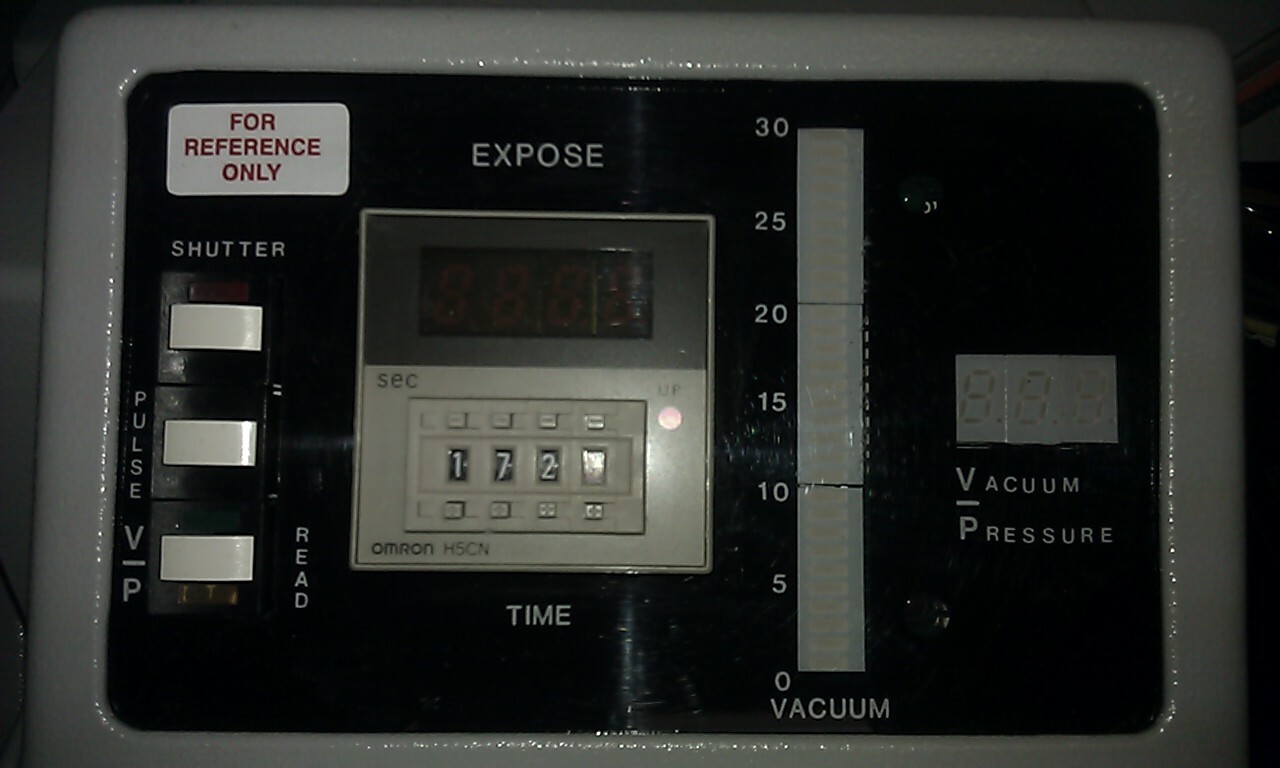

QUINTEL / NEUTRONIX 7000 Mask Aligner is a high-precision, automated machine used for photolithography processes. It is built for producing multiple integrated circuit (IC) designs from a single mask set. The machine consists of a main frame, a stage unit, an optics chamber, a camera, and an X-Y drive equipment. It provides superior alignment precision due to its dynamic two-axis video alignment capability, enabling high levels of accuracy for multi-level IC structures. A high-resolution digital camera provides alignment and focus sensing that is used to drive the stage to align accurately the integrated circuit design on the workpiece. The machine also has a powerful illumination system which uses a strong light source and special optics to minimize aberrations and reflections. Multi-level masks are correctly aligned with the workpiece with the X-Y drive unit, which features a self-diagnostic machine to constantly monitor and adjust for optimal operation. An automated destruction head ensures precise alignment of masks. The machine also has a wafer loader and unloader, which allows for efficient delivery of wafers. Additionally, QUINTEL 7000 is equipped with a built-in software suite which provides control, programming, and review processes. It is also capable of producing up to 15 wafers per hour, with a feature pattern accuracy up to 1.5 microns. Furthermore, the machine provides full support for on-site programming and repair, making it one of the most efficient and reliable mask aligners in the market.

There are no reviews yet