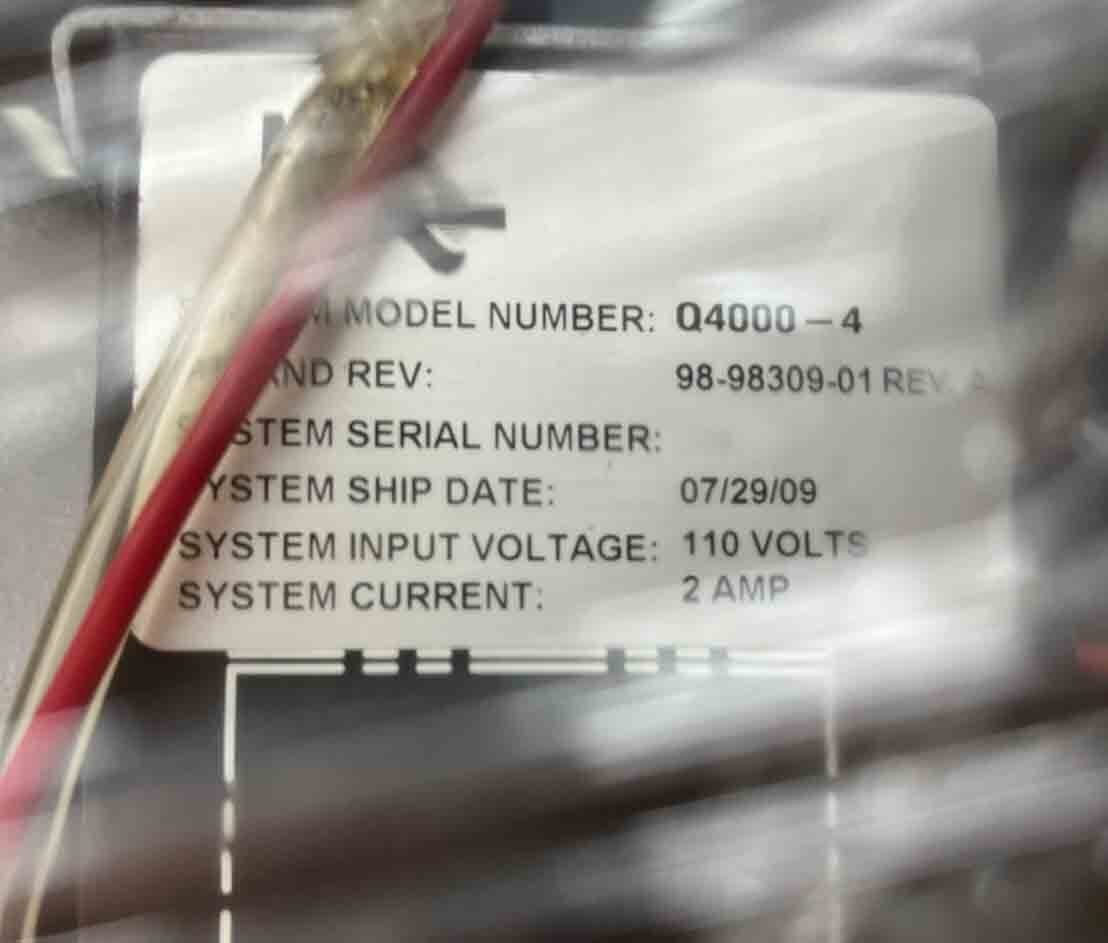

Used QUINTEL Q4000 #293636361 for sale

URL successfully copied!

Tap to zoom

QUINTEL Q4000 Mask Aligner is a high-precision machine used in the fabrication of sub-micron and nano-scale integrated circuits. It is designed for processing photomasks at high speed and high throughput. The equipment can be used for a variety of applications including lithography, etching and deposition. QUINTEL Q 4000 Mask Aligner consists of a number of components including a projection optics system, a mask table, a vacuum unit and a workpiece table. The projection optics machine is used to project an image of the mask onto the workpiece. The mask table holds the mask, which is typically a thin metal plate with an etched pattern on it. The vacuum tool is used to hold the mask and workpiece in place during the alignment process. The workpiece table is where the workpiece, such as a silicon wafer, is placed. To ensure accuracy and precision, the asset includes a highly advanced controller that can rotate, tilt, and adjust the position and size of the projected image. This enables the user to align the pattern on the mask precisely with the material on the workpiece. The model also includes a microscopy equipment, which can be used to inspect the alignment for imperfections and errors during the process. In addition to its precision and accuracy, the system has a high throughput rate. It can process up to 100 masks per hour and can process different mask sizes up to 1.2mm in thickness. The unit does not use harsh chemicals or require manual cleaning, further adding to its efficiency. Q-4000 Mask Aligner is an invaluable tool for the fabrication of sub-micron and nano-scale integrated circuits. Its high precision, accuracy and throughput make it perfect for high-speed processing and the production of complex integrated circuits.

There are no reviews yet