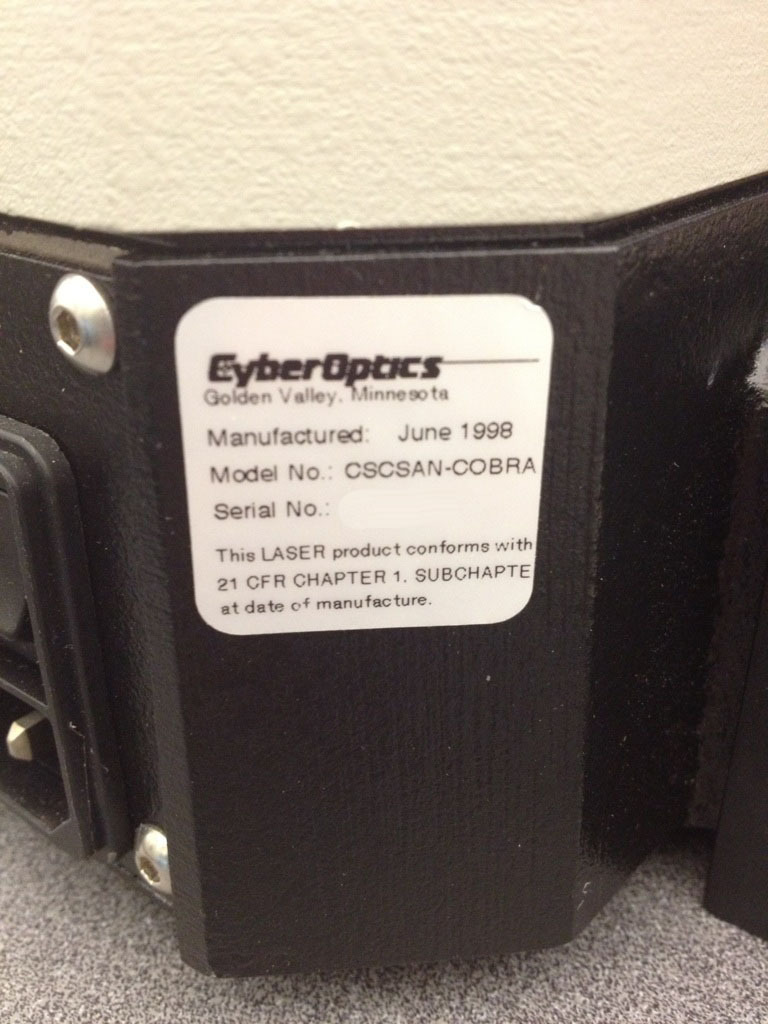

Used CYBEROPTICS Cyberscan Cobra #135777 for sale

URL successfully copied!

Tap to zoom

ID: 135777

Vintage: 1998

Laser Non-Contact Surface Profiler

Main unit: 50.8mm arm travel

Micrometer travel: 50.8mm focus

RMS stage flatness full travel: 2um

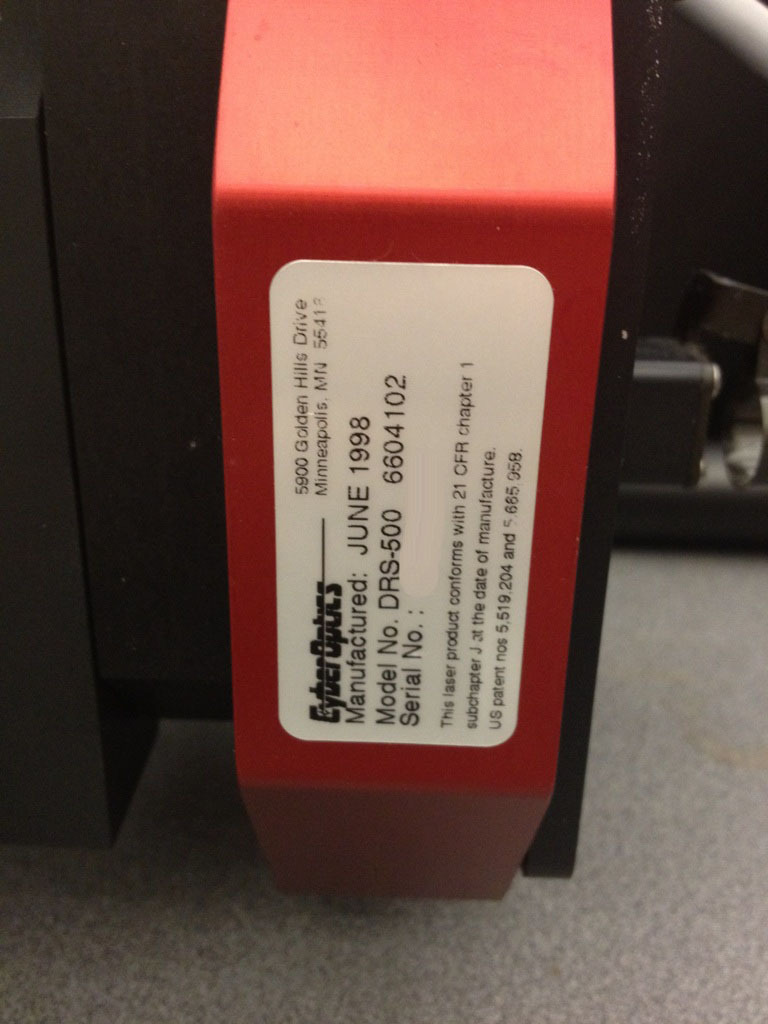

Keyence DRS-500 sensor:

Resolution: 0.125um

Accuracy: 1um

Standoff: 17mm

Spot size: 16 to 23um

Software not included

1998 vintage.

CYBEROPTICS Cyberscan Cobra is an automated mask and wafer inspection equipment used in the semi-conductor industry. It is designed to provide rapid, accurate and repeatable inspection of optical masks and wafers for defects. The Cobra consists of sophisticated optical inspection technology and a powerful software system for feature identification and characterization. The Cobra is based on state-of-the-art optics and illumination systems, providing the highest quality imaging. The unit features an telecentric optical design, utilizing large field of view optics for improved image resolution and a large field of view for reduced acquisition time. The imaging machine has integrated automated gain and offset compensation for consistent image quality over extended periods of time. The illumination source provides uniform illumination of the sample, enabling consistent imaging on all parts. The Cobra features advanced pattern recognition algorithms, enabling it to rapidly identify known defects, as well as determine the characteristics of any potential new defects. This tool provides a comprehensive defect identification, analysis and reporting asset including an advanced graphical user interface, comprehensive data analysis tools and comprehensive template and report generation capabilities. The Cobra is compatible with the leading semi-conductor fabrication equipment, and can be deployed with minimal disruption to existing process flows. It supports a wide range of applications, including last-stage defect identification and review, as well as identification of new, unidentified defects. The model incorporates capability to continuously learn new defects, cutting edge vision libraries, robust process integration and an intuitive user interface. The Cobra is designed to meet the most demanding standards for semiconductor production and mask lithography. It is capable of scanning samples at speeds of up to 2,000 parts per minute, ensuring fast, accurate and repeatable results. The equipment is designed for long service life and low maintenance requirements, and comes with a variety of performance options to meet specific customer requirements. Overall, Cyberscan Cobra is an advanced and powerful system for mask & wafer inspection, capable of providing rapid and accurate results with minimal disruption to existing processes. The unit is suitable for a wide range of applications and provides reliable performance in the most demanding semi-conductor fabrication environments.

There are no reviews yet