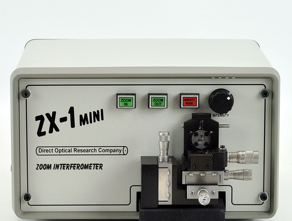

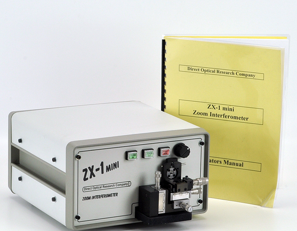

Used DIRECT OPTICAL ZX-1 Mini #127986 for sale

URL successfully copied!

Tap to zoom

ID: 127986

Zoom interferometer

Specifications:

Bare fiber holder chuck with X/Y/Z and tilt micrometers

Radius of curvature:

Reproducibility: 1 sigma: 0.25%

Repeatability: 1 sigma: 0.10%

Apex offset:

Reproducibility: 1 sigma: 2.0µm

Repeatability: 1 sigma: 0.5µm

Fiber height:

Reproducibility: 1 sigma: 1.5 nm

Repeatability: 1 sigma: 1.0 nm

Radius of curvature: 3mm Flat

Apex offset:

0-500µm (value calculated if outside of captured frame)

Fiber height: ± 6µm (with extended range option)

MICHELSON Interferometer (non-contact system)

Measurement Speed: less than 1 second

Magnification:

X85 to X550 using 12" monitor

X60 to X400 using a 15" XGA monitor and the digital zoom turned off

Operating wavelengths: 665nm (545nm with extended range)

Power requirements: 100 to 120V AC, 50 / 60Hz.

DIRECT OPTICAL ZX-1 Mini is a precision optical mask and wafer inspection equipment ideal for use in semiconductor manufacturing. Built with state-of-the-art technology, the system is designed to provide highly accurate measurements by analyzing the shape and topology of the masks or wafers being inspected. The highly-sensitive unit incorporates the latest optical technology, featuring a unique, drift-stable illumination machine that ensures maximum image quality and accuracy. The projected line pattern is resolved by the tool's two-channel line-detection method, ensuring an extremely accurate measurement of the device profile. With its low-noise imaging and digital edge enhancement, the asset can easily detect artifacts and other defects. In terms of its optical design, the model utilizes a Dual Column objective lens mounted on a rotatable platform, providing a wide range of magnifications. The combination of both column lenses enables the equipment to inspect the micro-structured device surface topography with high accuracy and provides the precision necessary for the detection of low contrast defects. Furthermore, the system employs a Dual Field Imaging alignment method for quick and accurate centering of the inspected devices. ZX-1 Mini unit is designed to provide repeatable results, making it Vertex's most reliable machine in terms of ease-of-use, accuracy, and repeatability of measurements. Its intuitive user interface allows for easy operation and its flexible software package enables automated operation and measurement. The tool can be used with a variety of masks, including chromium, carbon, quartz, stainless steel, and silver. Additionally, the asset is compatible with a number of wafers, including silicon and gallium arsenide. The model is also compact and lightweight, making it highly portable and ideal for use in any laboratory or on the company-floor. Overall, DIRECT OPTICAL ZX-1 Mini is a reliable mask and wafer inspection equipment that provides superior accuracy, sensitivity and repeatability. Its high-performance optics and advanced software make it an invaluable tool for the semiconductor industry.

There are no reviews yet