Used OSI Microvision 15 #5921 for sale

URL successfully copied!

Tap to zoom

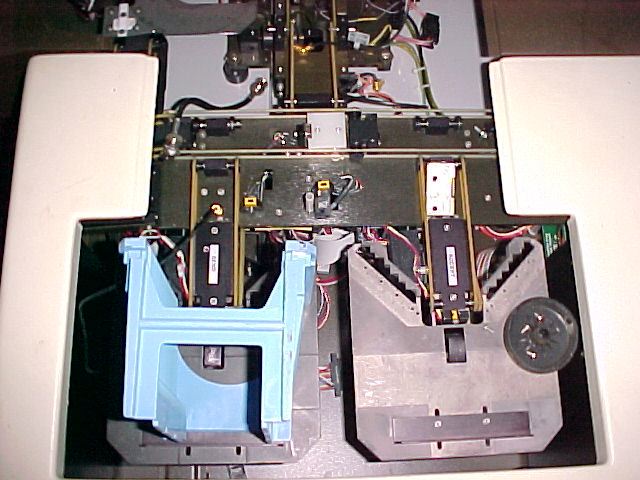

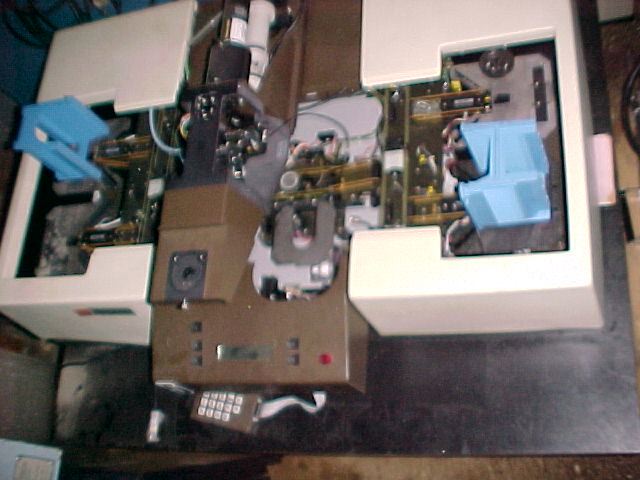

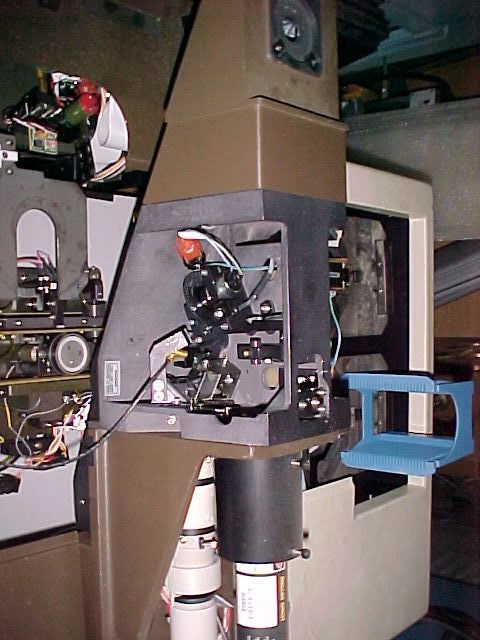

OSI Microvision 15 is a complex and powerful mask and wafer inspection equipment designed to detect, analyze and categorize defects across a range of semiconductor devices. Its advanced algorithms and imaging capabilities enable it to automatically identify and classify repairable and unreparable defects, thereby enabling quick and accurate maintenance and quality assurance operations. The system comprises a motorized, synchronized wafer transport unit, a high-resolution microscope, an acquisition subsystem, and a defect detection subsystem. The microscope, with a 5x zoom capability, is capable of magnifying defects up to 1000x. This allows the operator to see and record defects in unprecedented detail, as small as 0.20 microns! The acquisition subsystem, in conjunction with the microscope, allows the imaging of the entire wafer in a single scan. It utilizes several uses multiple CMOS and CCD cameras and bright-field, dark-field and oblique-angle imaging technology to accurately capture the fine details and nuances of wafer features. The defect detection subsystem is a powerful combination of pattern recognition technologies, ProgRama 's unique field-based defect products, and Metrosight's proprietary machine-vision algorithms. These technologies enable the machine to perform inspections, identify pattern defects, classify defects and separate them for further analysis. The collected data is then analyzed and classified by the tool's defect categorization tool, enabling quick and accurate sorting of key defects. After this, the data is exported to a patch-based defect review station, which provides the operator with detailed defect images, data analysis, and classification reports. With the reporting tools, operators are able to generate comprehensive reports with actionable information to identify and document defective wafers quickly and accurately. Overall, Microvision 15 makes up a comprehensive asset for automated mask and wafer inspection. With its advanced imaging and defect detection technologies, it can accurately identify, measure, and categorize any possible defects. In addition, it offers powerful reporting capabilities that allow operators to swiftly and accurately analyze defects and take corrective action. It is the perfect choice for any high-performance quality assurance operation.

There are no reviews yet