Used NEC DF-496 #9375867 for sale

URL successfully copied!

Tap to zoom

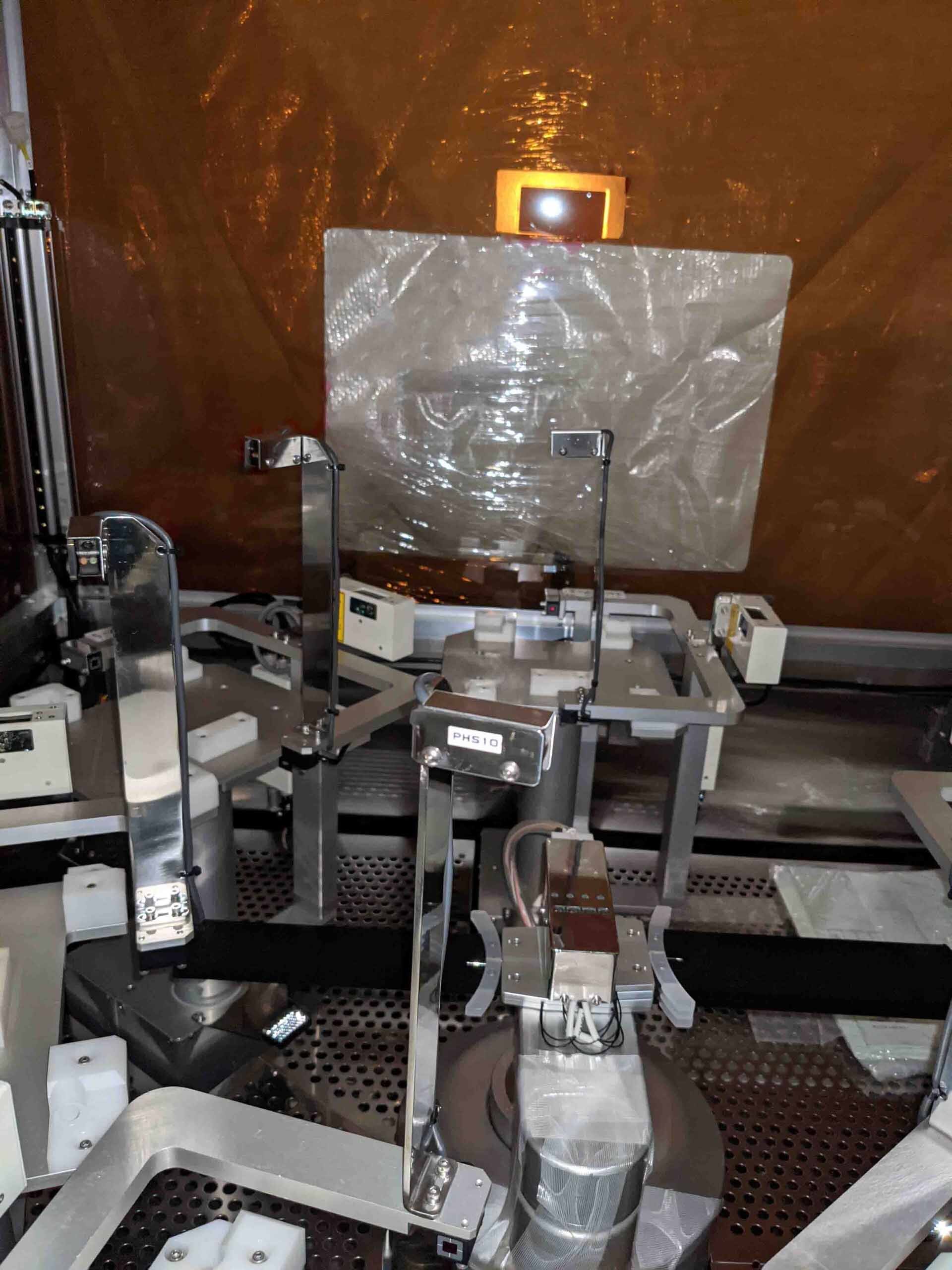

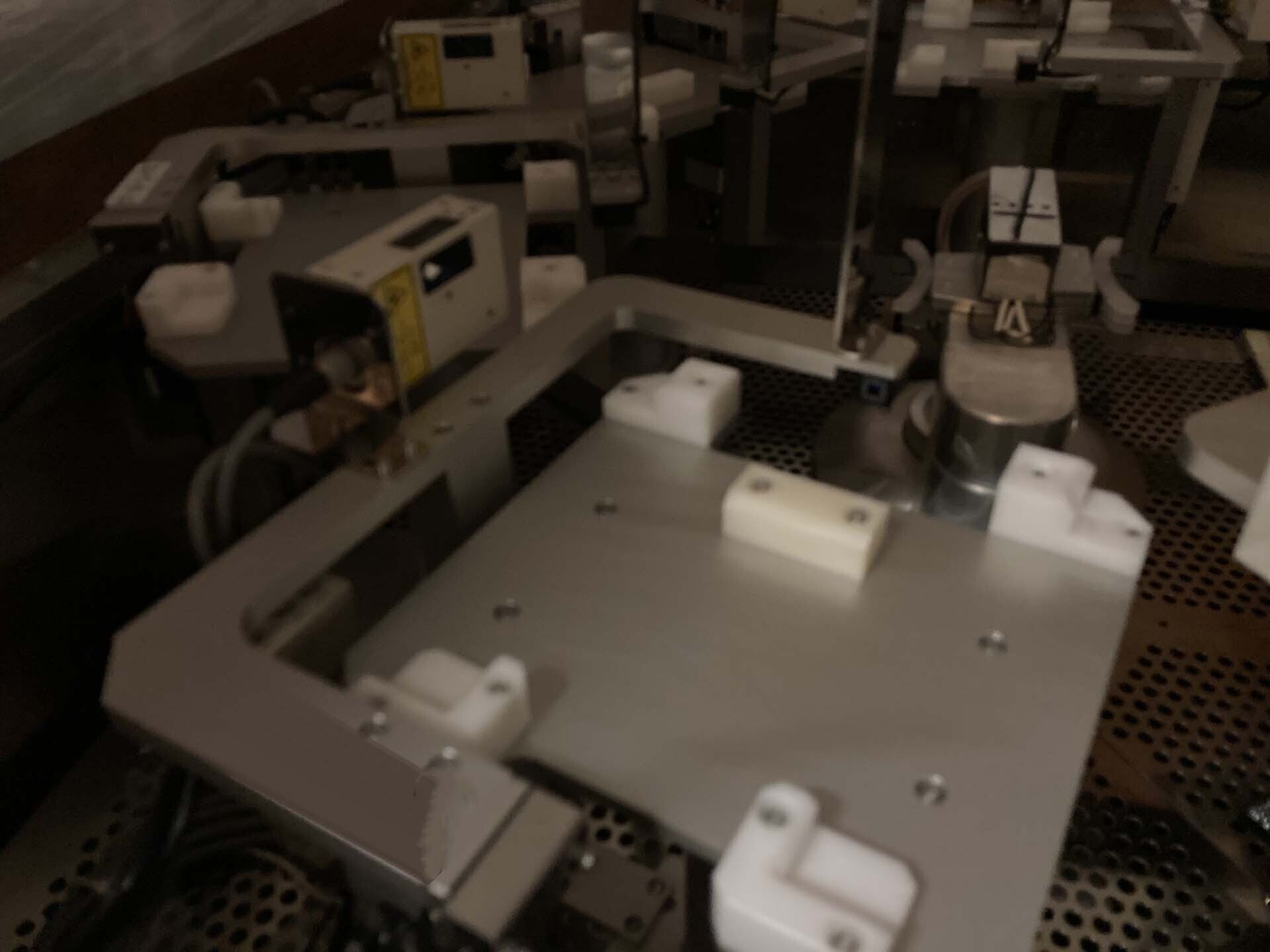

NEC DF-496 is a full-featured wafer processing equipment designed to meet the needs of high-volume and cost-sensitive semiconductor processing operations. This state-of-the-art system offers a number of unique features that enable robust and reliable processing of wafers with advanced features. The core of DF-496 includes an advanced multi-axis robotic arm for precise positional alignment of wafers, ensuring accurate positioning during all operations. The unit also includes an integrated vision machine, which allows wafers to be accurately located prior to processing. This tool is also capable of controlling multiple tools, which can be used in a variety of wafer processes such as dicing, wet/dry film coating, bus bar wiring, electroless plating, etching, and chemical processing. NEC DF-496 also includes advanced software and controller for precise control of all asset components, as well as integration of third-party software for maximum flexibility. The controller is also linked to an LCD touchscreen, allowing end users to configure the model with ease. The equipment is designed to handle a range of wafers, such as quartz, glass, hard quartz, and sapphire. The system supports a variety of substrates, including foil, niobium (Nb), nickel (Ni), aluminum (AL), and copper (Cu). DF-496 also supports manual feeders, automatic feeders, and wafer mounters to accommodate a variety of needs. The unit is easy to use, making it ideal for a variety of applications such as semiconductor wafer production, integrated circuit (IC) fabrication, and flat panel display (FPD) production. The machine is capable of handling high-volume and cost-sensitive processes, and its advanced features enable superior and reliable performance. NEC DF-496 is a reliable and feature-rich wafer processing tool that can meet the demands of high-volume production. With its advanced robotic arm, integrated vision asset, and flexible controller, the model ensures reliable and precise wafer processing for a variety of processes.

There are no reviews yet